How To Maintain An Efficient Blast Media Work Mix

How To Maintain an Efficient Blast Media Work Mix

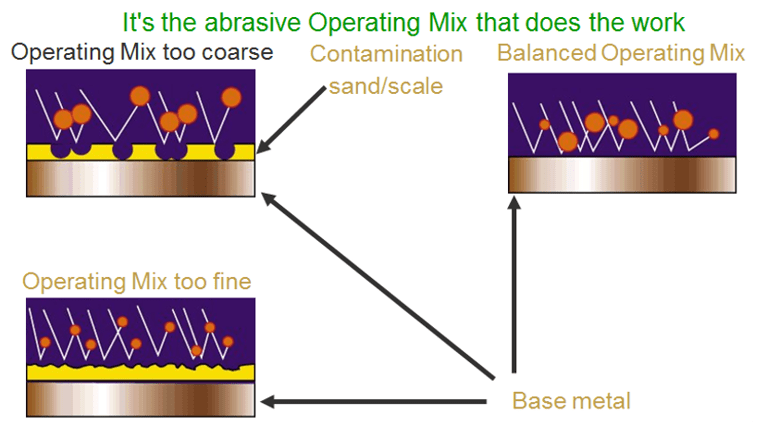

If you are reclaiming and reusing your blast media, then you need to maintain a healthy blast media work mix. Having too coarse or too fine of a work mix can cause inconsistent or damaged surface finishes. The best way to ensure a consistent and quality surface finish is through maintaining a healthy blast media work mix.

Signs of A Bad Work Mix

Process is moving slowly.

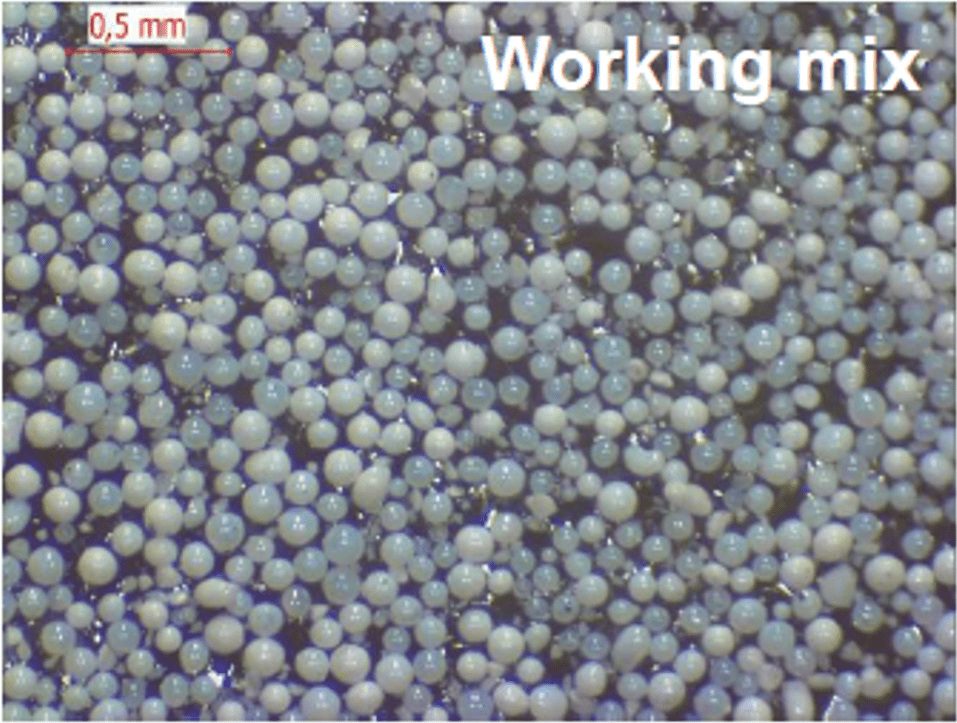

A proper work mix contains a mixture of various sized abrasives. This distribution of sizes provides for maximum cleaning in the shortest amount of time.

There is a lot of dust in your process.

The fine dust particles are not being pulled out by the reclaimer/dust collector properly.

Inconsistent surface finish.

Whether the part is needing a smooth finish or being prepped for coating, having an even surface is important. If your blasting is producing an inconsistent finish, you should check your media mix by screening.

Benefits of Using A Healthy Blast Media Mix

There are many benefits to utilizing a blend of sizes in your blasting operation. Some of those benefits include:

- Reduce waste of your blast media by ensuring it is working as efficiently as possible, ultimately saving you money.

- Produce high quality finishes on a consistent basis.

- Increase productivity through a quicker blasting operation. An efficient work mix will achieve the desired finish faster than an inconsistent mix.

How To Achieve & Maintain An Efficient Work Mix

Monitor your work mix through regular screening

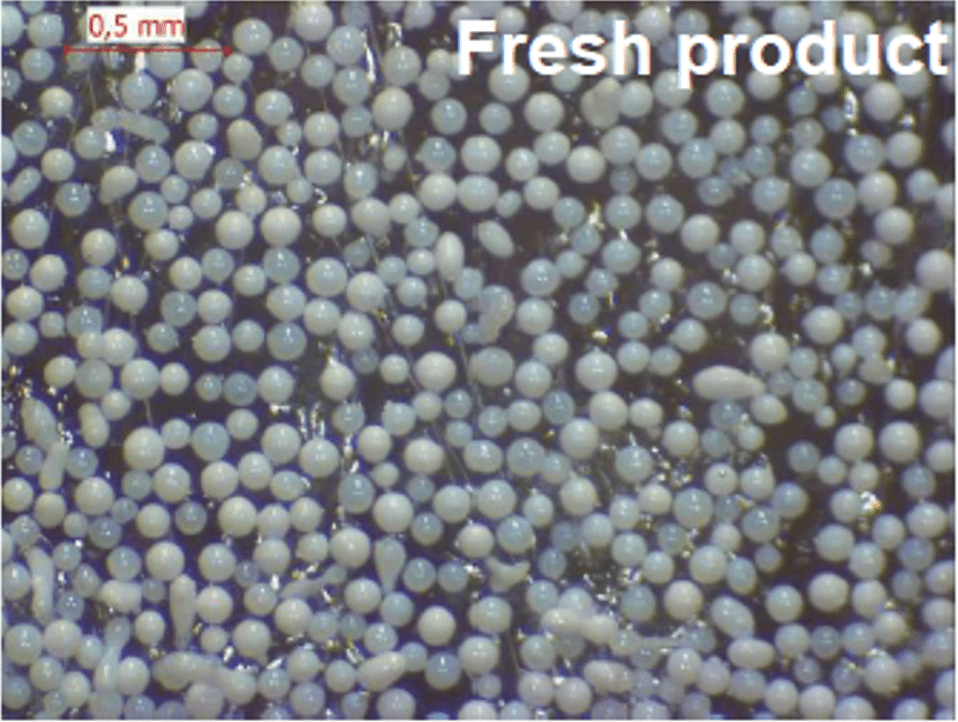

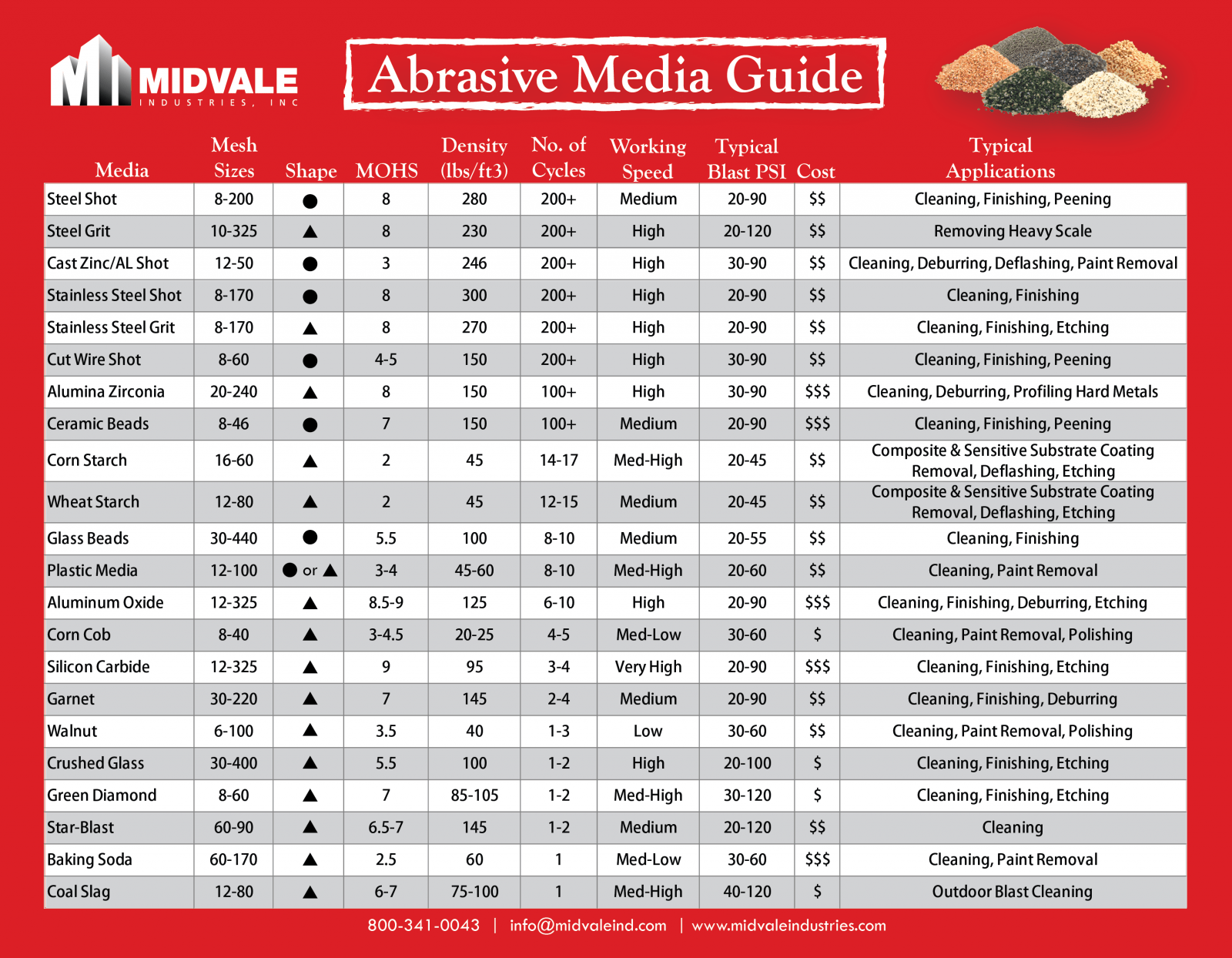

There are a lot of factors that cause a media to break down quickly or slowly such as the type of abrasive used, the starting particle size and PSI used while blasting. Since there can be many factors that affect the rate of media breakdown, it is a good idea to regularly screen your media so you can tell where your system stands. This is turn will help you make adjustments that will provide a consistent quality finish.

If you don’t have screening capabilities, we can help at our lab at Midvale Industries.

Regularly add new media to the mix

Frequently adding small media additions will keep larger particles fed into the system to replace the spent media that is being removed. The amount of blasting you do per day will help determine how frequently you should add new media.

Adding a large amount of new media at the end of the current media cycle will throw off your work mix. This creates an inconsistent mix and results.

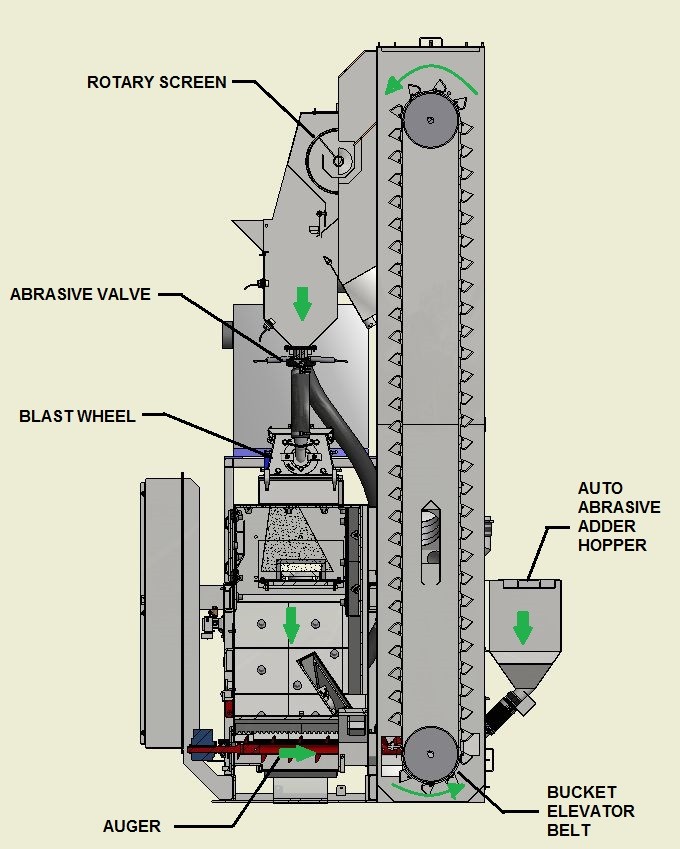

Check your dust collector

If you find usable media in the dust collector, make adjustments to the reclaimer and/or dust collector that will dampen the system and stop pulling good media through.

Is there dust in your work mix?

Then it’s time to adjust the reclaim/dust collector system the opposite way and pull spent media and other dusts out of the system.

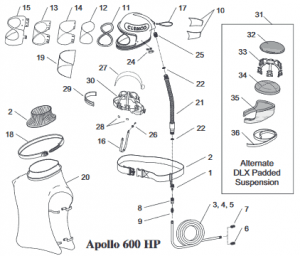

Whether you are new to blasting or have been around for a little while, it’s helpful to the names of the parts of your blast helmet. This will help you when ordering new parts for your helmet and also to understand better what the various components do. To the left is a sample breakdown of an Apollo 600 Blast Helmet (a best seller in the blasting industry). See pdf links below to see labeled parts breakdown of the Apollo 600 blast hood HP and LP models.

Whether you are new to blasting or have been around for a little while, it’s helpful to the names of the parts of your blast helmet. This will help you when ordering new parts for your helmet and also to understand better what the various components do. To the left is a sample breakdown of an Apollo 600 Blast Helmet (a best seller in the blasting industry). See pdf links below to see labeled parts breakdown of the Apollo 600 blast hood HP and LP models.

Recent Comments