Shot Blasting Equipment

Shot blast equipment utilizes repeatable blast angles to provide consistent quality finishes in an automated blasting environment. The unique engineering of this equipment provides full surface shot blasting or shot peening for a wide range of parts. Shot blast machines provide an economical approach to automation and remove the blaster from the blast room.

Shot blasting equipment is designed for metal cleaning, shot peening and deburring.

Spinner Hanger Shot Blast Machine

Spinner Hangers provide ideal solutions for batch blasting parts that are either too fragile or awkward for other methods of automated finishing.

Table Shot Blast Machine

Table Blasters provide full blasting coverage on parts weighing up to 10,000 pounds, with diameters up to eight feet, and heights exceeding four feet.

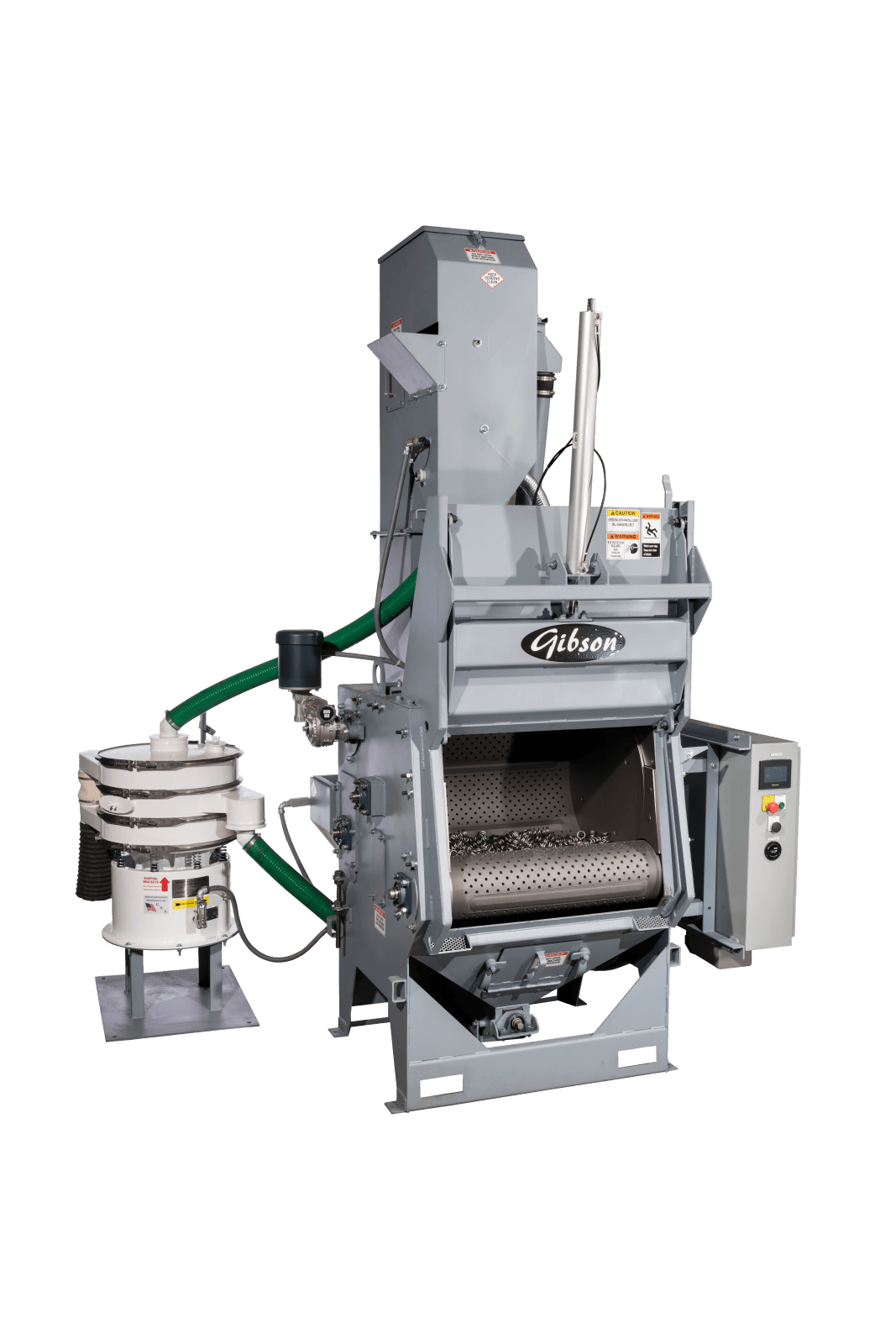

Tumble Shot Blast Machine

Tumble Blasters process multiple small to medium size parts, with a level of speed and efficiency unmatched by other types of equipment.

Monorail Shot Blast Machine

Monorail blast systems are fully automated blast systems designed for 24 hour production. They blast heavy parts at a high rate.

Mesh Belt Shot Blast Machine

Wheel blast systems with a manganese mesh belt conveyor help automate the blast process and reduce high labor costs.

Pipe Shot Blast System

Pipe Wheel Blast Systems are fully automated machines that remove rust, mill scale and create a surface profile for coating adhesion.

Shot Blast Parts

We carry a selection of replacement shot blast parts for Gibson Wheel Blast Equipment and high wear parts for other major wheel blast brands.

Replacement shot blast parts include:

- Blades

- Buckets

- Elevator Belts

- Feed Hose

- Liners

- Tune Up Kits

- Valves

Shot Blast Equipment Repairs

Midvale Industries offers industrial maintenance and repair services for shot blast equipment. Our technicians are trained to work specifically with wheel blast equipment. Repair services provided:

- General Maintenance & Repairs

- Motor Rebuilds

- Auger Repair & Replacement

- Separator Optimization

- Blast Pattern Optimization

- Dust Collector Maintenance & Repair

- Machine Retrofits & Upgrades

- Blast Wheel Tune Up

Custom Shot Blasting & Peening Solutions

Let our team help engineer the best solution for you!

Learn More About Gibson Shot Blast Equipment

Midvale Industries is a proud partner of Gibson Abrasive Equipment for all shot blast solutions. Find more details and literature at the Gibson Abrasive Equipment website.