Cellular Blasting Equipment

Cellular Blasting Equipment

Cellular Blasting Equipment

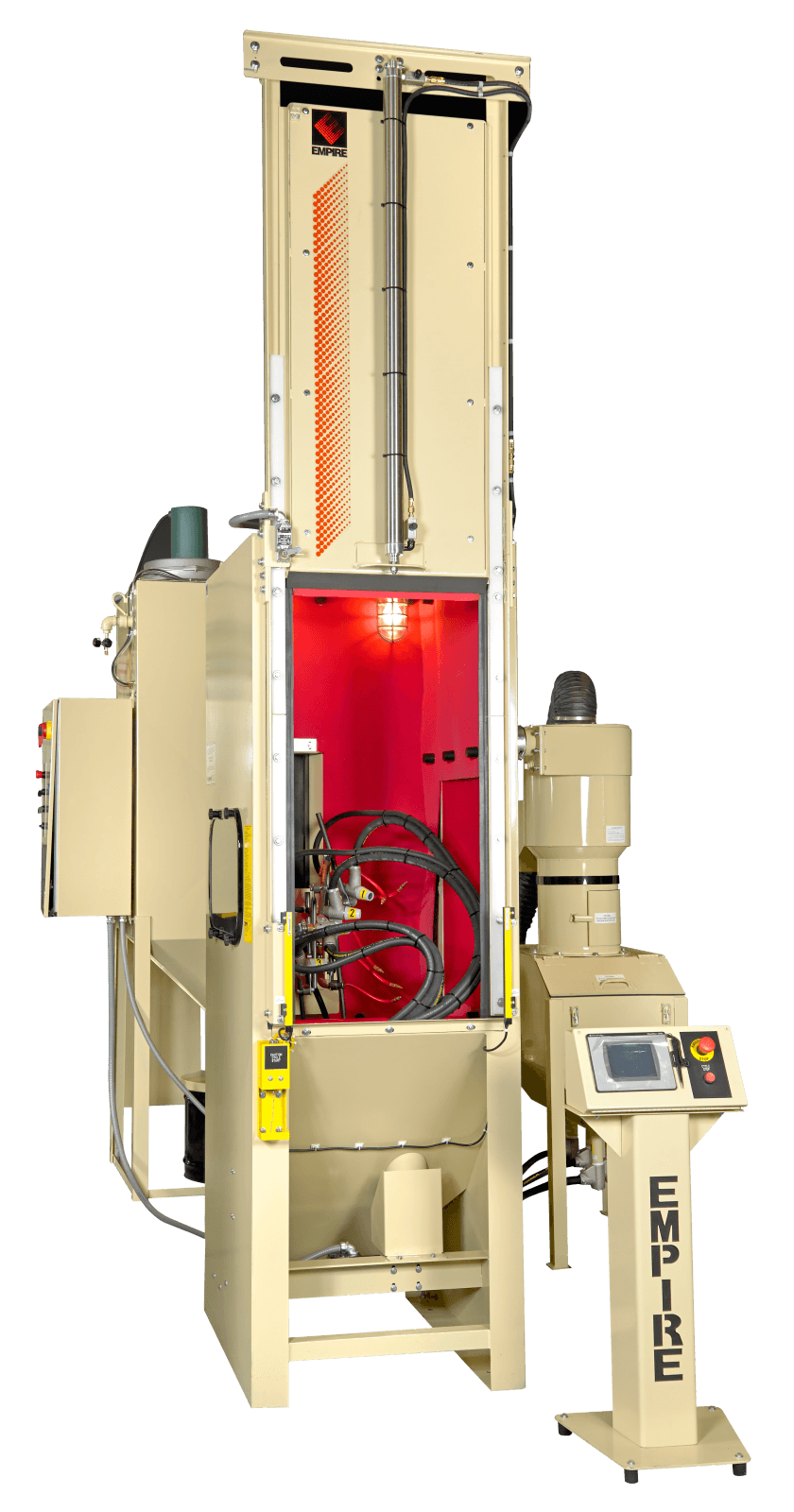

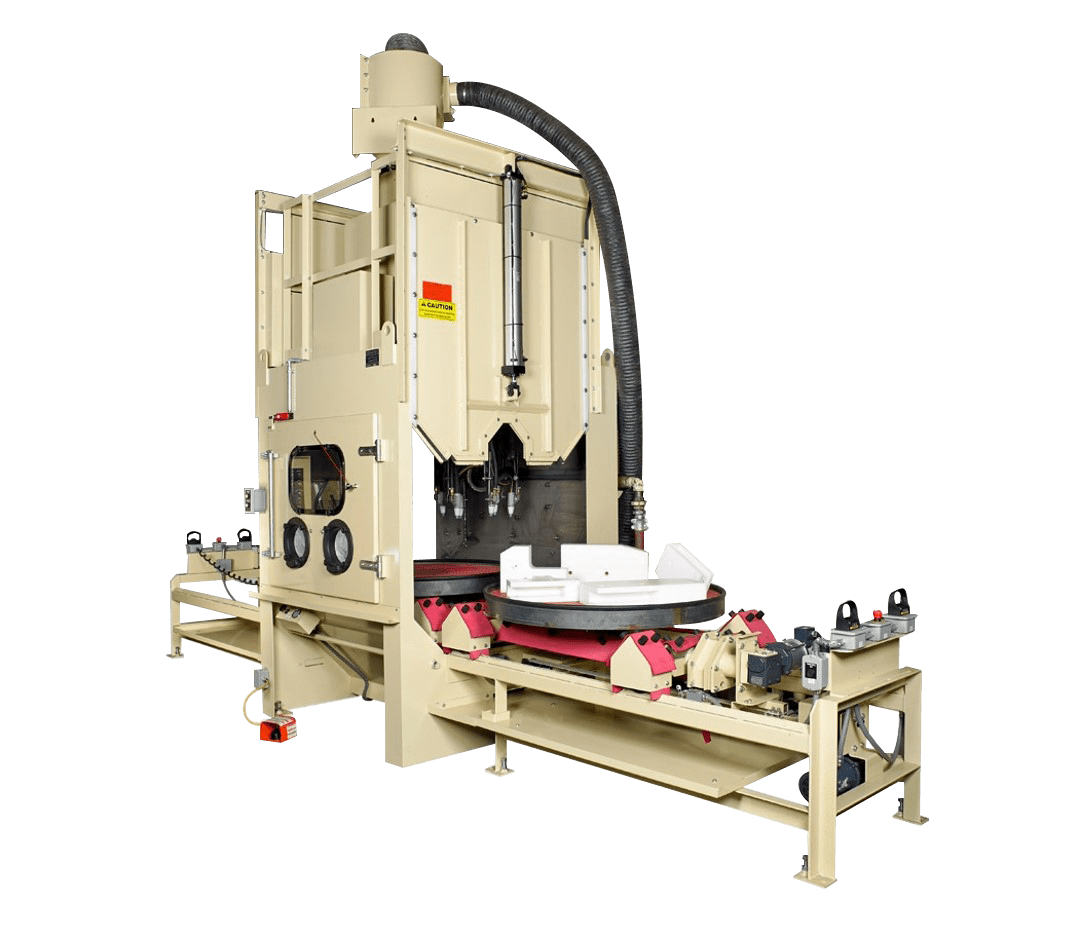

Cellular blast equipment provides economical automation single-station for blasting small parts. The blast enclosure is large enough to process a variety of parts within a produciton facility, making it ideal for short runs on multiple parts. The cellular machine has a small footprint, freeing up valuable floor space within the facility. Each sized unit comes with media reclamation and dust collection, providing air quality and return on media investment.

Size Options

- 38″ Deep x 30″ Wide x 65″ High Cabinet

- 24″ Deep x 24″ Wide x 30″ High Cabinet

Key Benefits

- Small Footprint

- Economic Automotion

- Multiple Part Capabilities

Have A Question?

Contact us today to talk to a LIVE representative. We can answer your questions, set up a site visit, or work out details for a trial of our products! Our team of technically trained sales representatives are backed by years of industrial knowledge and practice to help develop the best processes for your applications.

Recent Comments