Pipe Shot Blast Equipment

Pipe Shot Blast Equipment

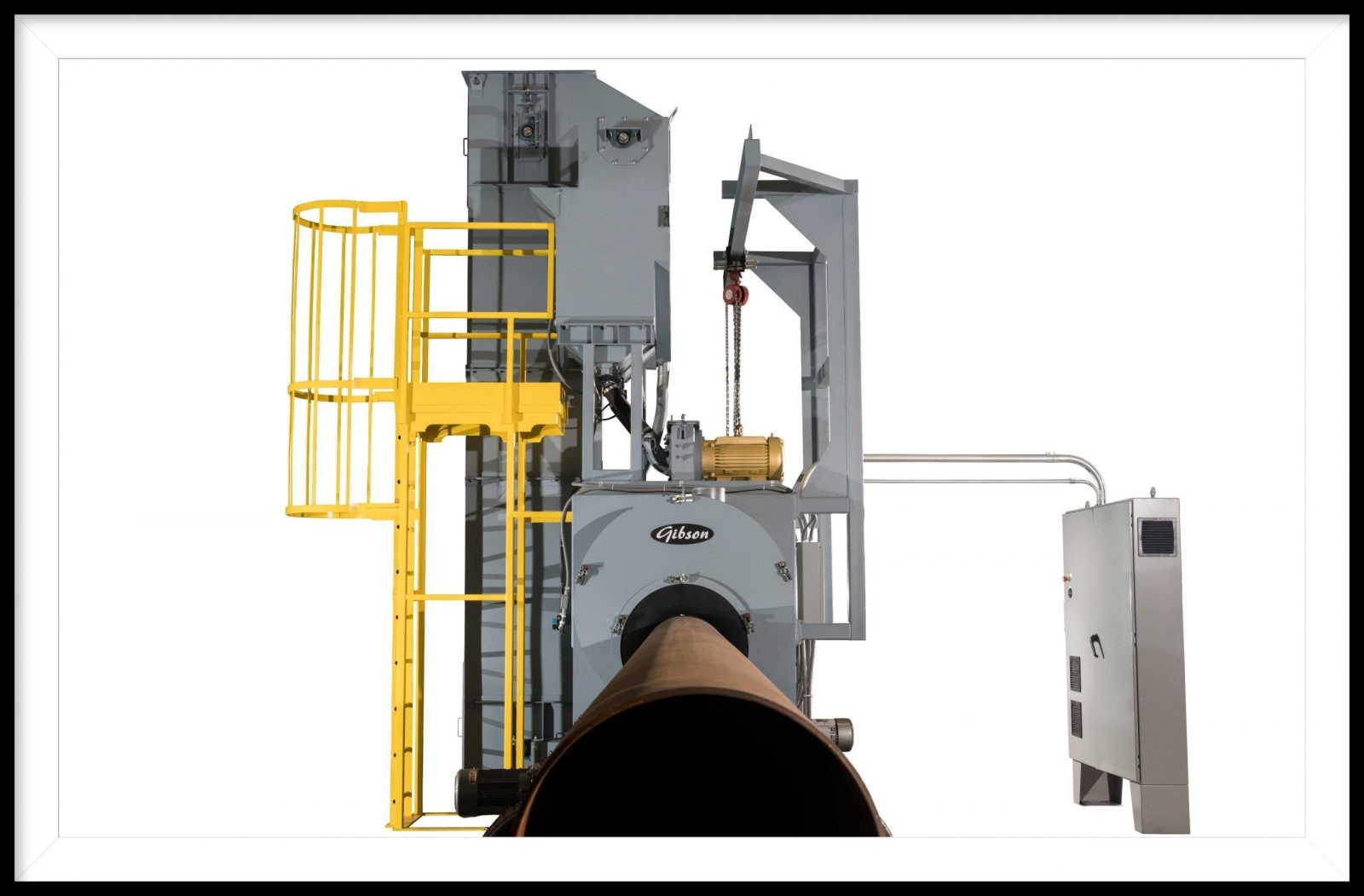

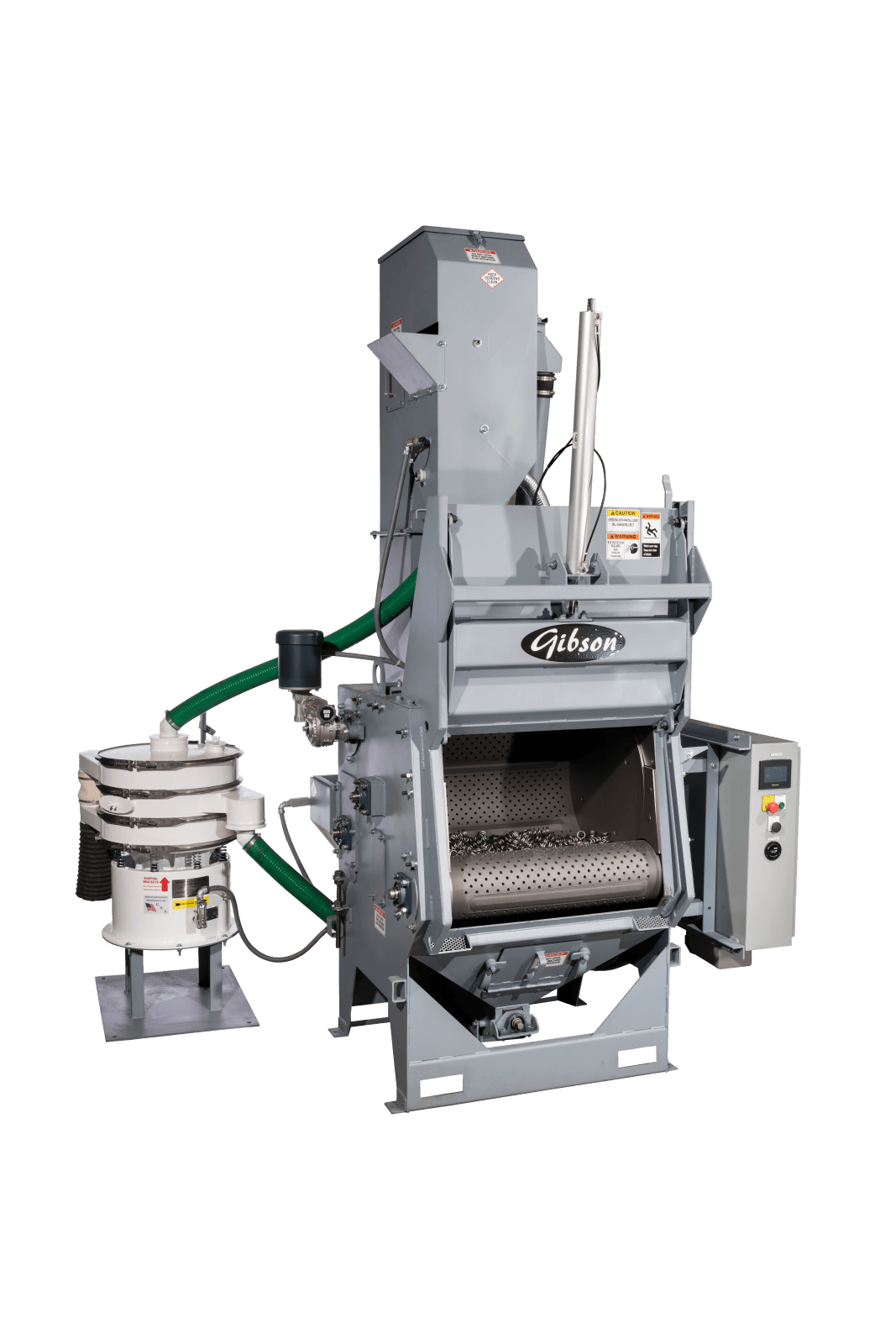

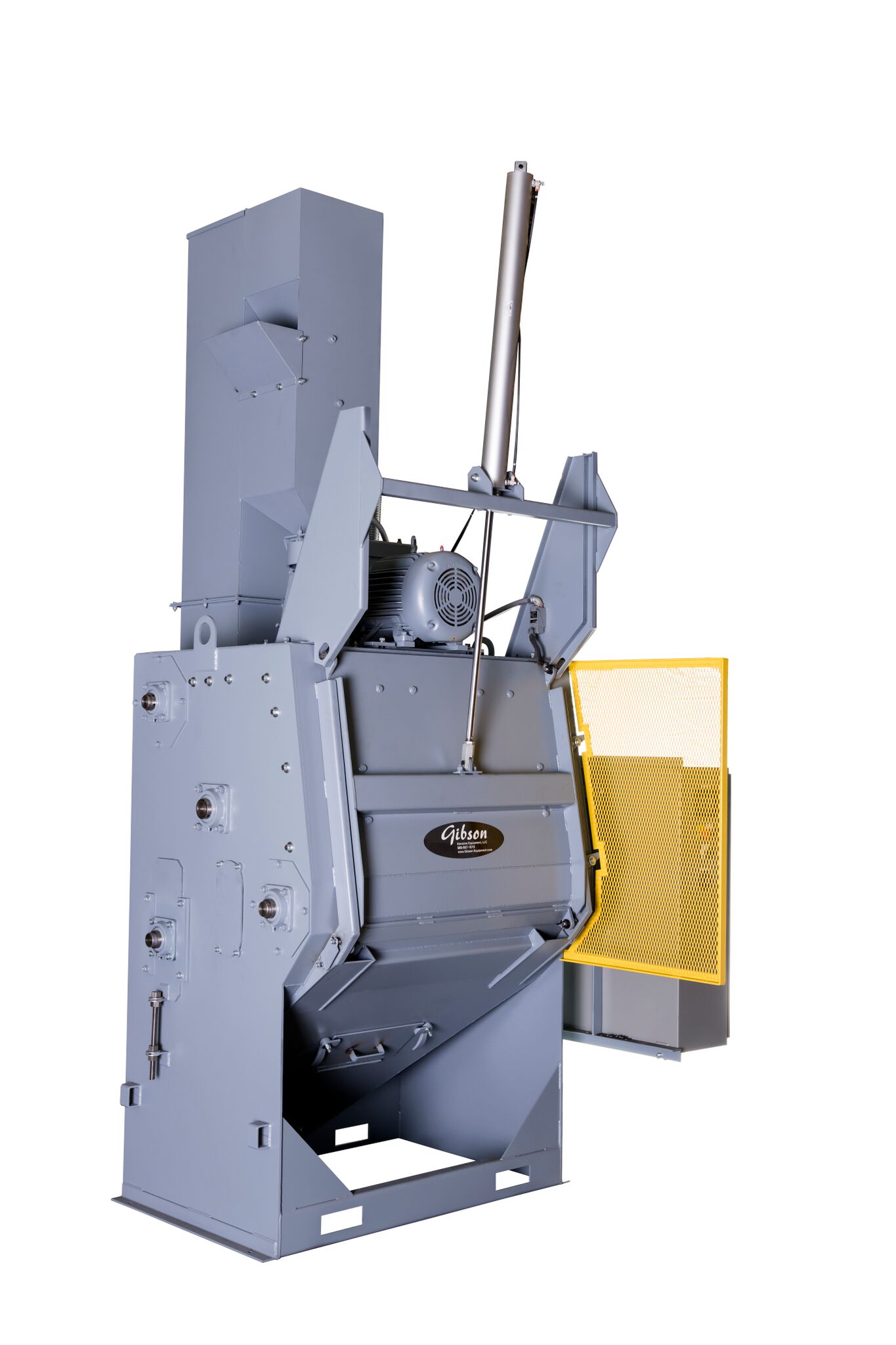

Pipe Shot Blasting Machine

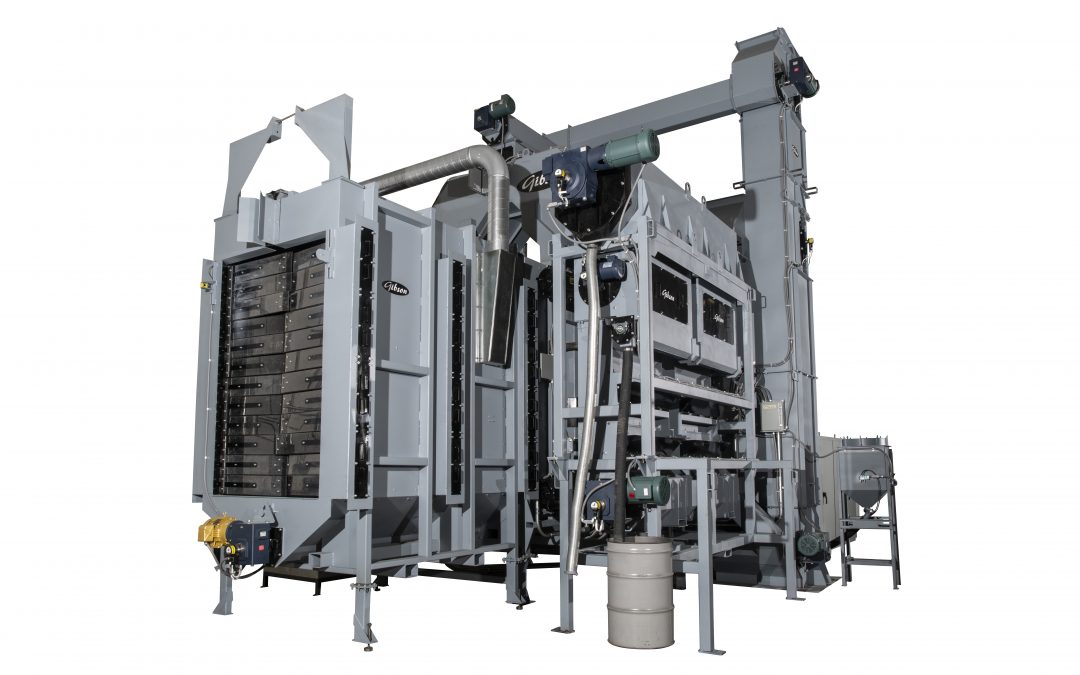

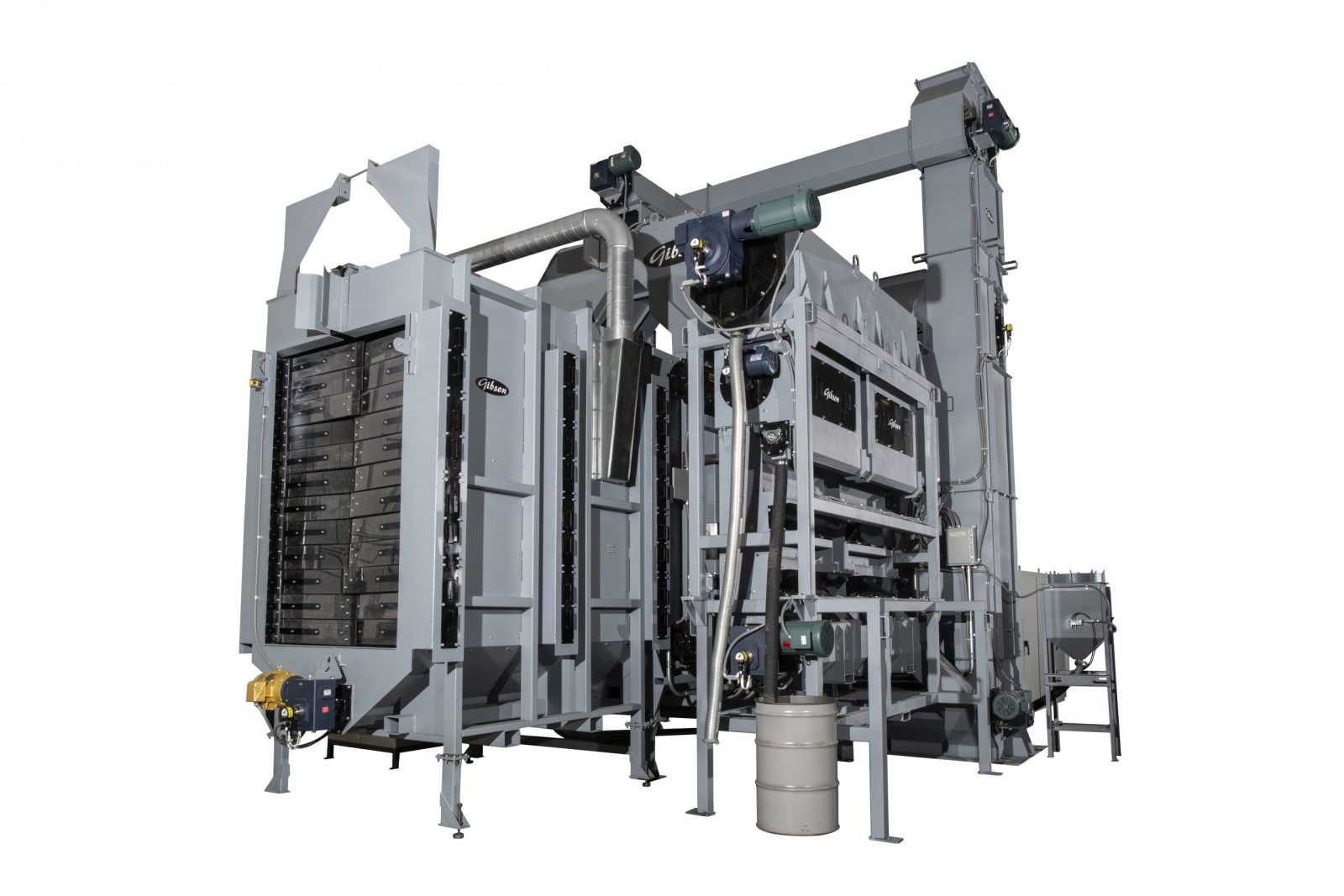

Midvale Industries offers fully automated pipe shot blast equipment for the removal of rust, mill scale, and to create a surface profile for proper coating adhesion.

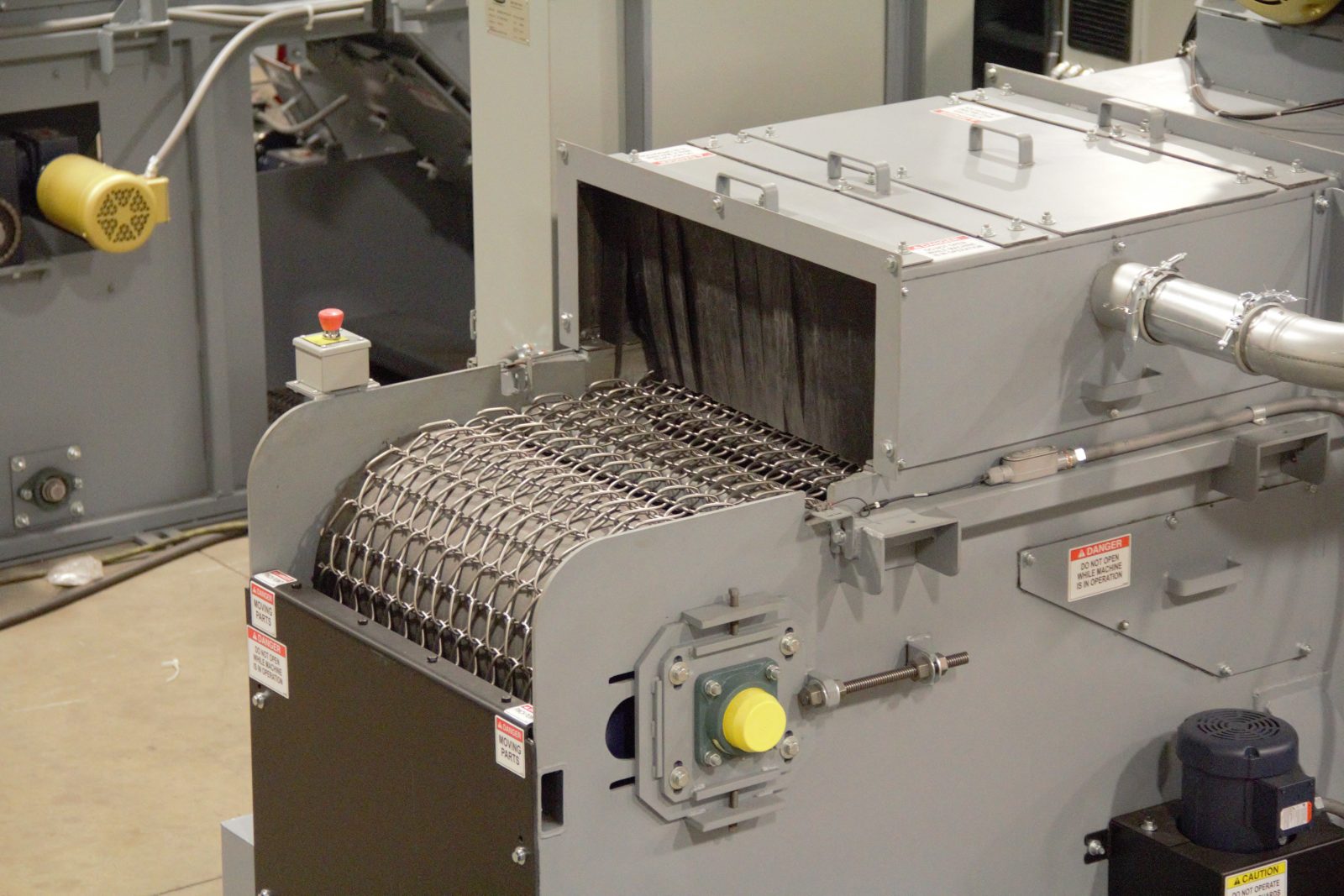

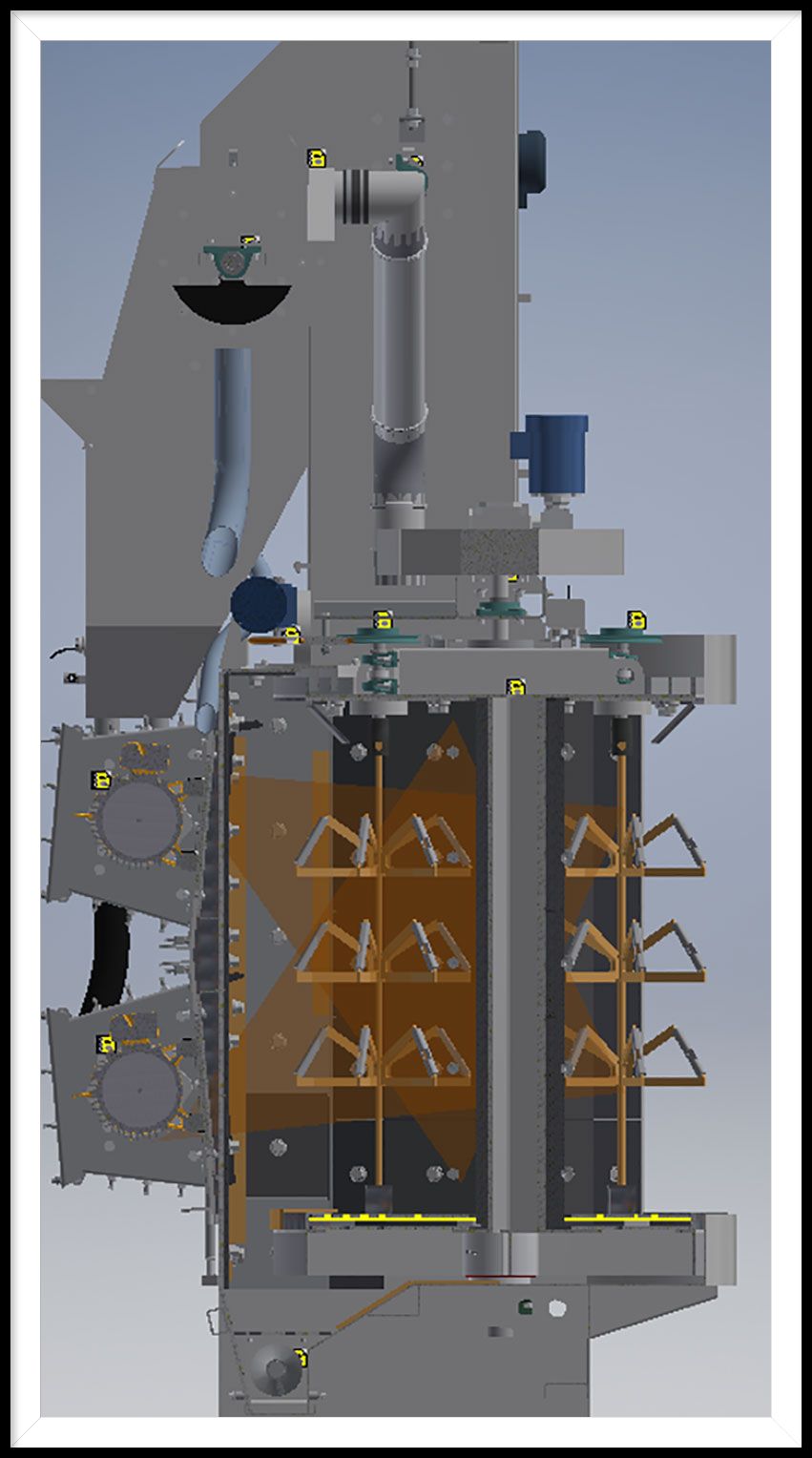

These systems include skew roll blast systems that are designed to clean pipe or other long and round material. The skew roll conveyor not only keeps round parts in place but rotates them 360 degrees while conveying them through the blast chamber.

A range of system sizes are offered cleaning up to 42” of pipe at variable rates.

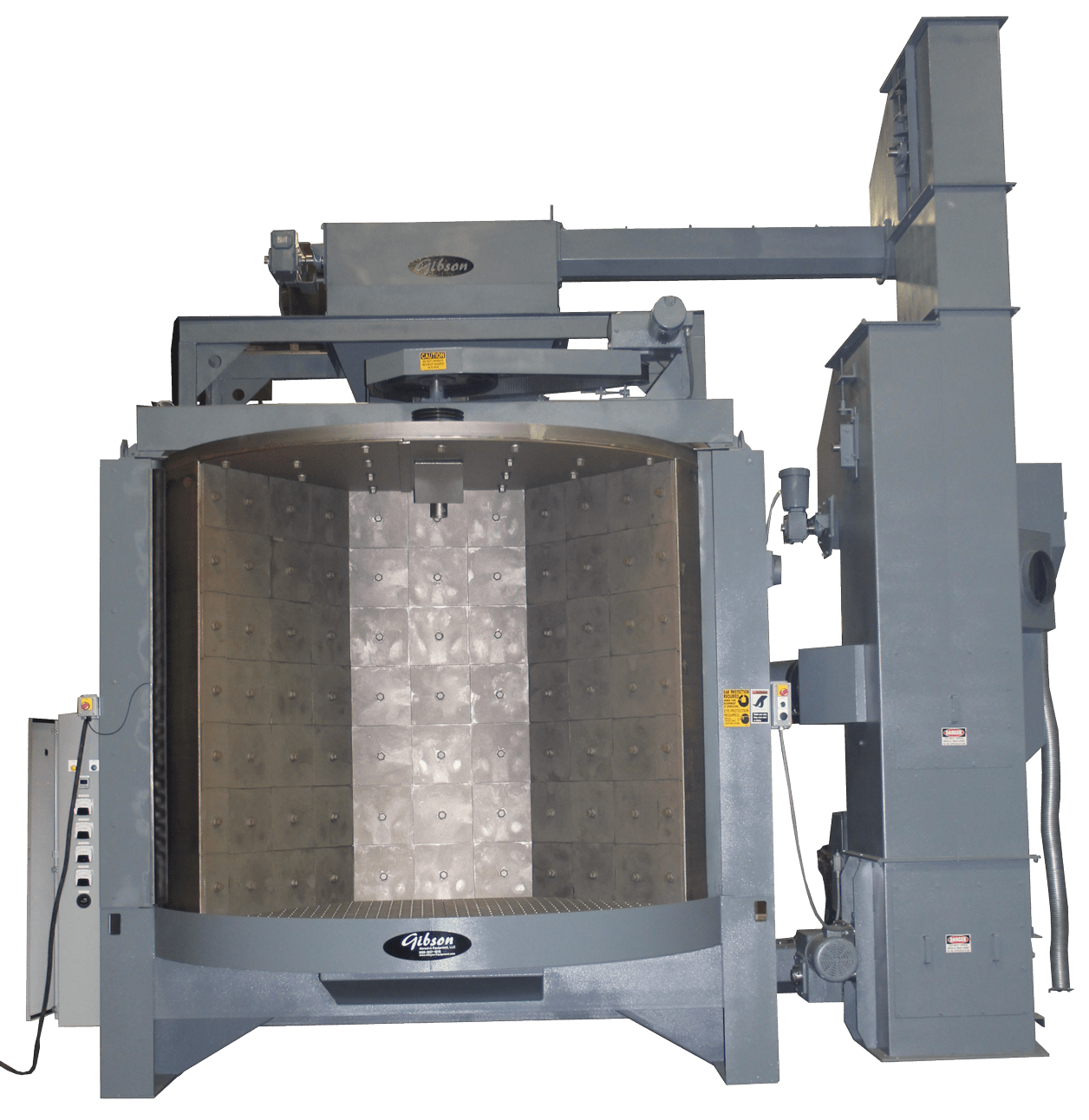

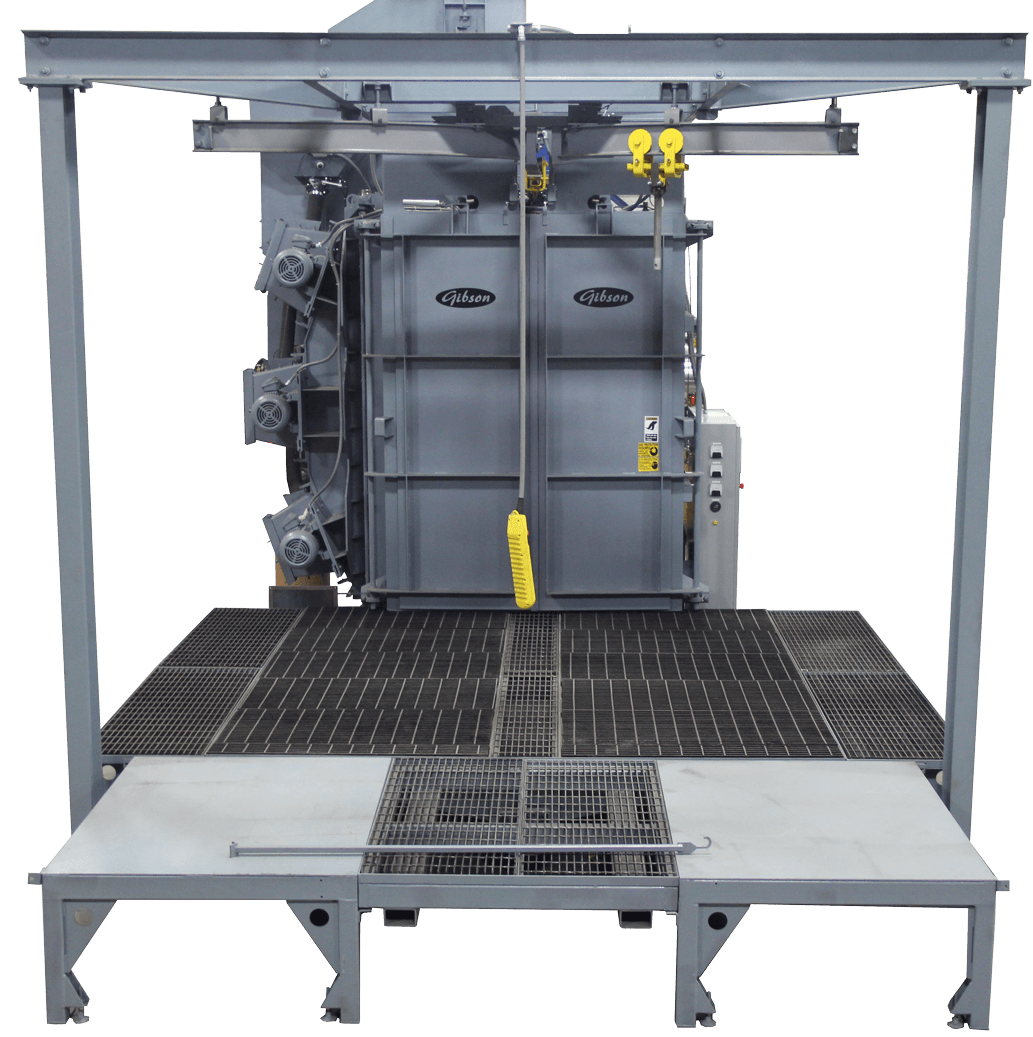

For processing, parts are loaded onto a powered turntable which rotates within the blast envelope to provide 360° exposure to the blast stream. Models with an oscillating blast wheel, such as our 36″ Power Table, enhance blast coverage. Features like the swing door expedite loading and unloading by enabling the operator to sway the system’s door-mounted turntable in and out of the blast enclosure.

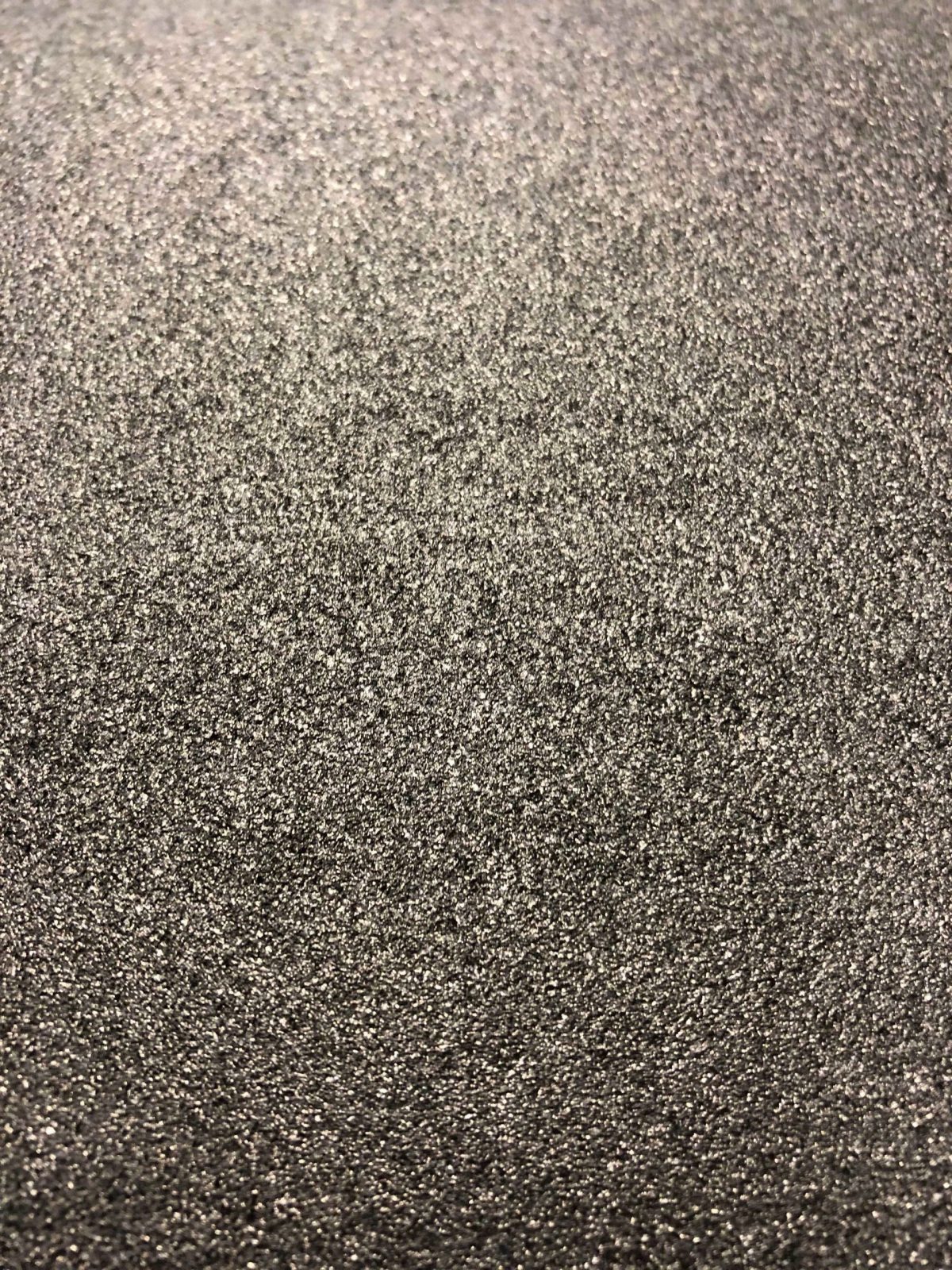

Pipe Before Shot Blasting

Pipe After Shot Blasting

Talk To Our Team About Shot Blasting Equipment

Contact us today to talk to a live representative. We can answer your questions, set up a site visit, or work out details for a trial of our products! Our team of technically trained sales representatives are backed by years of industrial knowledge and practice to help develop the best process for your applications.

Recent Comments