https://midvaleindustries.com/wp-content/uploads/2024/08/OSHA-Compliance-1-2.png

900

1600

Nate Riggins

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

Nate Riggins2023-01-03 19:17:302026-03-02 09:13:38OSHA Compliance for Cleaning Solvents

https://midvaleindustries.com/wp-content/uploads/2024/08/OSHA-Compliance-1-2.png

900

1600

Nate Riggins

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

Nate Riggins2023-01-03 19:17:302026-03-02 09:13:38OSHA Compliance for Cleaning SolventsAqueous parts washers are grouped into two classifications of parts washing equipment: spray parts washers, and immersion parts washers. Each method of cleaning is effective for different applications and types of parts. Understanding how each type of parts washer works is an important part of the equipment selection process. Now, let’s dive into how each one works.

Main Types of Parts Washers

Spray Parts Washers

A spray parts washer utilizes high pressure spray nozzles to remove contaminants. While water is the main cleaning agent, aqueous cleaners can be added within the process. Spray washers have built-in blow off options to help remove moisture after the cleaning process. Spray washers come in many types of systems including cabinets, conveyor, monorail, and more. The cleaning processing time is usually quick.

Immersion Parts Washers

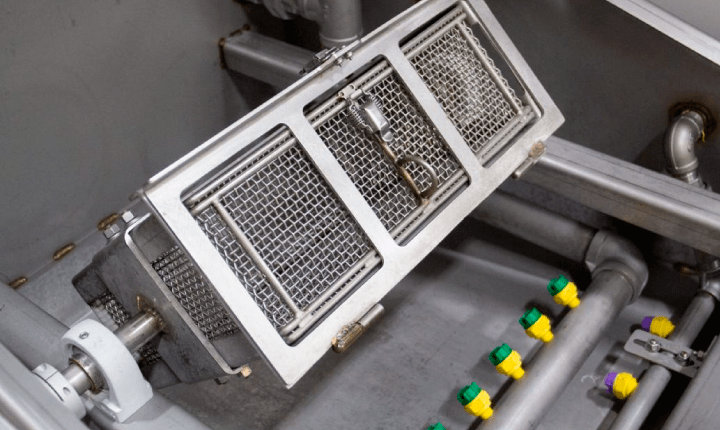

The immersion parts washing process utilizes a basket holding the parts that are then dipped into the tank of water and solution. The chemical energy of the solutions works with the mechanical energy of the equipment to remove the contaminants. Agitation and ultrasonics can be added for extra cleaning power. This is ideal for parts with a lot of small cavities. The cleaning processing time usually takes longer.

Main Types of Parts Washers

Considerations for Selecting an Industrial Parts Washer

Now that we have a base knowledge of how each type of parts washer functions. Let’s address some things you need to consider when selecting what type of parts washer equipment is best for your cleaning application.

1. Cleaning Chemistry

Prior to selecting the parts cleaning equipment, the chemistry needs to be addressed by asking whether aqueous or solvent based cleaning best for your application. The contaminants that you are cleaning are the key factor in this decision. Tough oils require a different process than other contaminants. Therefore, knowing what will be cleaned off the parts is an important process in determining your cleaning chemistry.

Here is a breakdown of aqueous and solvent solutions:

Benefits of Solvent

- Cleans oil better and faster than aqueous.

- Best material compatibility (multi-metal compatibility).

- Water free process = no flash rust and quicker drying time.

- Can clean at lower temperatures.

- Has a longer bath life and can be distilled/re-used for overall cost reduction.

- Allows for adjusting time.

- Best fit: applications with precise cleaning specifications.

Benefits of Aqueous

- Can clean a variety of contaminants (oil, water-soluble coolants, rust, carbon).

- Allows for adjustment of time, concentration, and temperature.

- Environmentally safe.

- Easy and economic disposal.

- Low cost per gallon.

- Best fit: remanufacturing and tough-to-clean applications.

When selecting your chemistry, you need to think about the solution concentration, temperature needed requirements, exposure period, and waste management. It’s suggested to have your parts test cleaned to find the best chemistry for your application. Learn more about cleaning chemistry here.

2. Cleaning Parameters and Specifications

The four main components to cleaning parameters and specifications for consideration are temperature, concentration, duration, and dryness. Parts washers vary in the options they can provide to meet these parameters. Depending on the needs of the cleanliness specs, you may need multiple cleaning stages or blow-off/drying stages.

When your parts have cleanliness specifications that need to be met, make sure that the equipment can meet them. You can request a test on the parts to ensure that it meets your standards. There are multiple methods of testing we provide in our lab including white glove/cotton swab, dyne, millipore, and gravimetric testing.

3. Part Geometry

Complex parts with multiple or long cavities require extra consideration when selecting a washer. Immersion with vertical agitation and/or ultrasonics is often the best fit for these cavities, but other times strategically aimed spray nozzles is the best method.

4. Batch Processing vs Continuous Processing

The overall processing needs of your parts manufacturing will help determine the type of parts cleaning system you select. Will you be washing parts in batches, or will you need a continuous cleaning process?

The batch cleaning process allows for greater flexibility in the shape and quantity of parts you clean at a time. The continuous cleaning process does offer some flexibility. However, they are designed to process similar shapes and quantities of parts at a high rate to keep the overall manufacturing process running quickly and without interruption.

Batch Processing

Continuous Flow

5. Material Handling

One aspect of part flow that needs to be considered with your equipment plans is material handling. The most common method is manual loading the parts onto a conveyor, table or into a basket. Auto-loading or robotics increase reliability in the parts handling process by removing the operator from the position and allowing them to focus on other duties. Determining how the parts will get to and from the parts cleaning equipment will play a factor in the long-term floor space needed for the project.

6. Production Volume

Some parts washers are ideal for small batches of cleaning per cycle, while others are ideal for large batches in an ongoing process. Identify your batch size and the number of batches that need to be cleaned per shift.

7. Facility Layout

Facility layout and flow can factor into the type of equipment you select for your parts washing process. We all know that floorspace is a premium and can be hard to come by. Matching the parts cleaning parameters with the available floorspace is a vital step in selecting a parts cleaning system.

If your production line runs on an in-line and automated system, then you’ll want to look at a parts washer that can be integrated into that system. The other item to look at is speed. Ask yourself, “how quickly do the parts need to be washed before continuing with production?”

8. Budget

Now comes the part of the discussion no one really wants to talk about, budget. As with most industrial equipment solutions, the more options there are, the higher the cost. Knowing the required specifications, expected volume, and desired outcomes will help you determine the size of budget you should invest into parts washing equipment.

There are often other costs associated with a parts cleaning application that can be forgotten in the planning process such as:

- Utility costs

- Regular bath maintenance – draining, cleaning and re-filling the solution/water mixture

- Waste water management and disposal

Don’t be caught off guard by these expenses when planning your budget.

Now You’re Ready to Research Your Parts Cleaning Needs

When selecting a parts washer, there are many things to consider. However, the most important consideration is your part(s) and the contaminant(s) that you will be cleaning. In simple terms, if the parts surface is mostly visible with simple shapes, spray washing is usually ideal. If your part needs to soak or has non-visible surfaces, immersion is typically ideal. There will be exceptions, so it is best to talk to a trained cleaning consultant about your needs first, then request a lab test.

Remember that everything covered here can help confirm whether or not a specific parts washer system is right you.

Take advantage of our processing labs to test chemistry and parts cleaning processes to ensure you have the best process for your application. Talk to our team today!

Share This Post

More Like This

https://midvaleindustries.com/wp-content/uploads/2024/08/OSHA-Compliance-1-2.png

900

1600

Nate Riggins

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

Nate Riggins2023-01-03 19:17:302026-03-02 09:13:38OSHA Compliance for Cleaning Solvents

https://midvaleindustries.com/wp-content/uploads/2024/08/OSHA-Compliance-1-2.png

900

1600

Nate Riggins

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

Nate Riggins2023-01-03 19:17:302026-03-02 09:13:38OSHA Compliance for Cleaning Solvents