Midvale has been great to work with, following up regularly on every stage of the project, from start to finish. They have provided all the information needed from the beginning that helped us determine the correct equipment needed to improve production at our facility.

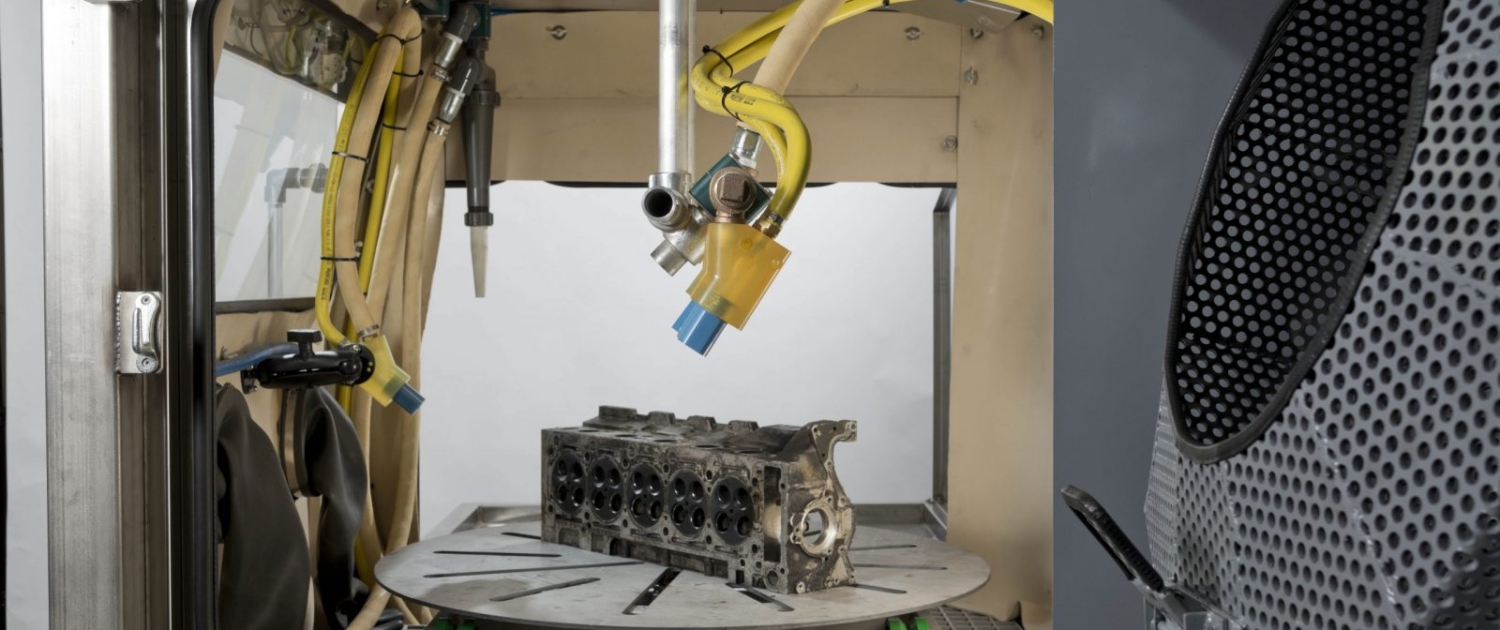

The Gibson shot/blast cabinet has reduced the time to prepare items for painting by an average of 1/10th of the time previously needed. The Paint Booth has not only saved us a significant amount of time in man-hours it has also drastically reduced our paint cost.

Midvale has provided professional service at every phase: sales, delivery, install, and service. I would highly recommend them to any company looking to improve production, save money on consumables as well as reduce man hours.

– Cliff