Green Diamond Foundry Sand

Green Diamond Foundry Sand

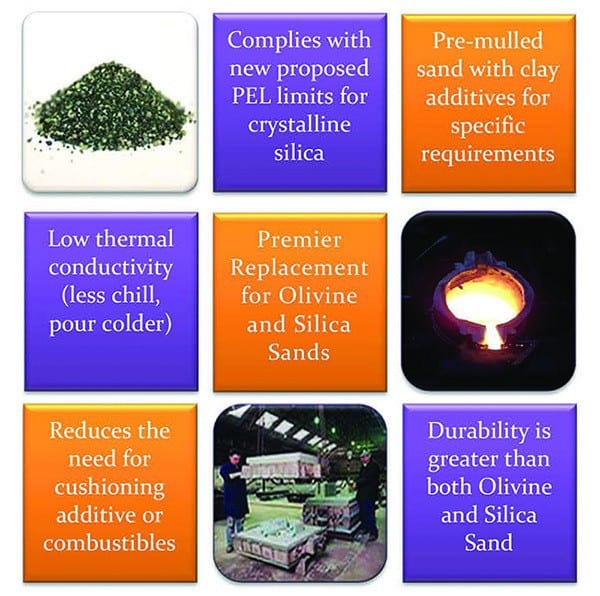

Green Diamond is available in ferrous and non-ferrous foundry grade sands. It is the ideal replacement for olivine and silica sands for molding and coremaking and it complies with the new proposed PEL limits for silica (it contains no crystalline silica). Due to low thermal expansion, Green Diamond foundry sand reduces the need for cushioning additives or combustibles.

Green Diamond foundry sand is offered in a wide range of screen distributions as well as special order pre-mulled sands with clay additives to meet your specific requirements. Ask our team about a sample and we can schedule a trail in your sand system.

Mined and Manufactured in the United States

Key Benefits:

- Improved casting finish

- Sub-angular shape provides high permeability

- Low thermal expansion

- Reduced pouring temperatures

- Lower bulk density than silica sand

- Contains no crystalline silica and approved as environmentally safe

Available in many AFS blends, including very fine sizes.

Ask us about our custom pre-mulled blends.

Several sizes in-stock and ready to ship.

Olivine Sand Alternative

Green Diamond foundry sand is a reliable alternative to a silica or olivine green sand system. It’s mined and sourced in the United States and is silica free. The quality of the castings are superior when using Green Diamond.

Screen Analysis Documents

Ferrous Green Diamond Screen Analysis

Non-Ferrous Green Diamond Screen Analysis

Additional Documents

Pre-Mulled Foundry Sand

Save time and eliminate the mixing process with pre-mulled Green Diamond foundry sand. Pre-mulled sand is a customer-driven sand recipes that offer a turn key solutions to foundry sand systems. You pick the recipe, we’ll mull it and package it, so when it arrives to the foundry, it’s ready to be introduced to the sand system in high volumes, without the fear of compromising mold strengths.

Example: AFS 100 Green Diamond, 6% Southern Bentonite, 1.5% Water

Choose your recipe and let us mull the sand for you.

What is Green Diamond Foundry Sand?

Green Diamond sand is mined and manufactured in the United States. It is a synthetic olivine sand that has been processed by melting, then granulated by quenching in water. It has the same advantages as natural olivine, but has no crystalline silica and low thermal expansion. This minimizes, or eliminates expansion defects.

It has a lower bulk density than traditional silica sand, which means you get more molds or cores per ton of sand, and it has a higher permeability. It has no loss on ignition, which means that it cannot give you pitting defects, or gas, as can be seen with some of the natural Olivines.

Have A Question?

Contact us today to talk to a LIVE representative. We can answer your questions, set up a site visit, or work out details for a trial of our products! Our team of technically trained sales representatives are backed by years of industrial knowledge and practice to help develop the best processes for your applications.