Robotic and Automated Wet Blast Equipment

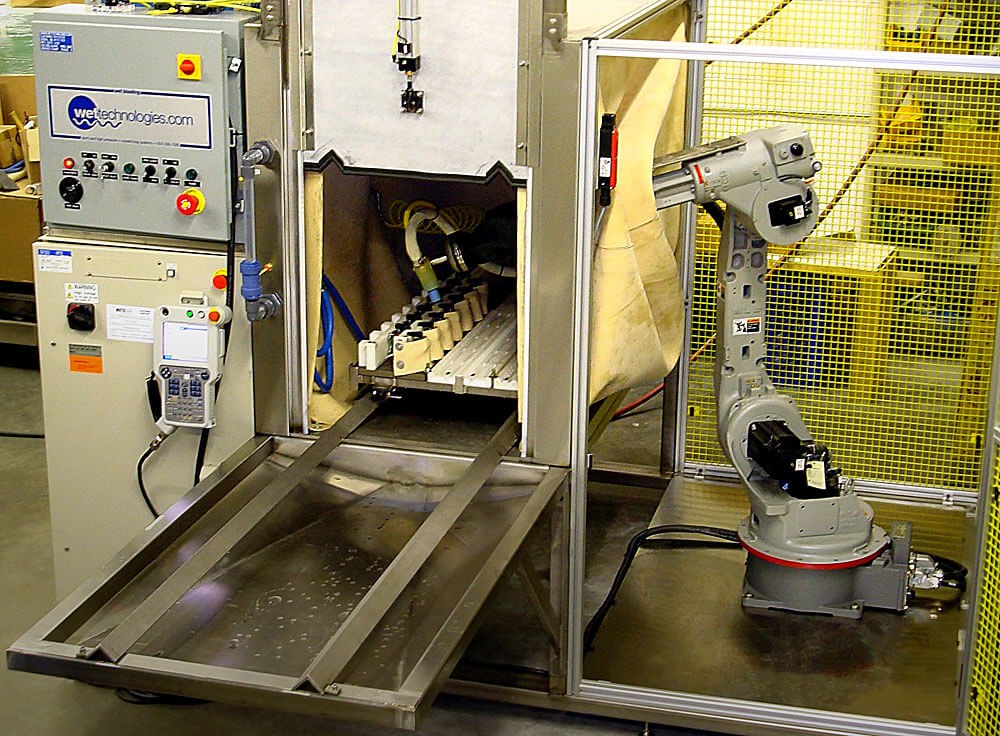

Robotic Wet Blasting Equipment

Robotics have become viable to the productivity of applications and processes. Due to part handling and delivery with a multi axis robotic system, parts that require multiple moving nozzle angles are good candidates for Wet Tech designs. Alternatively, the part itself can be manipulated by a robot, with the slurry nozzle(s) in either stationary or moveable positions. In addition to being a Motoman Service Provider (MSP), we also integrate Fanuc, and other 6- and 7-axis robotic systems for industrial and military applications.

- Wet blasting creates smooth and precise finishes while reducing abrasive embedment. It also eliminates many of the dust problems associated with traditional blast cabinets, while preserving the abrasives longer than traditional dry blasting.

- Wet Blasting typically uses no chemicals, only water and abrasives in a closed loop system. This makes abrasives highly recyclable and longer lasting.

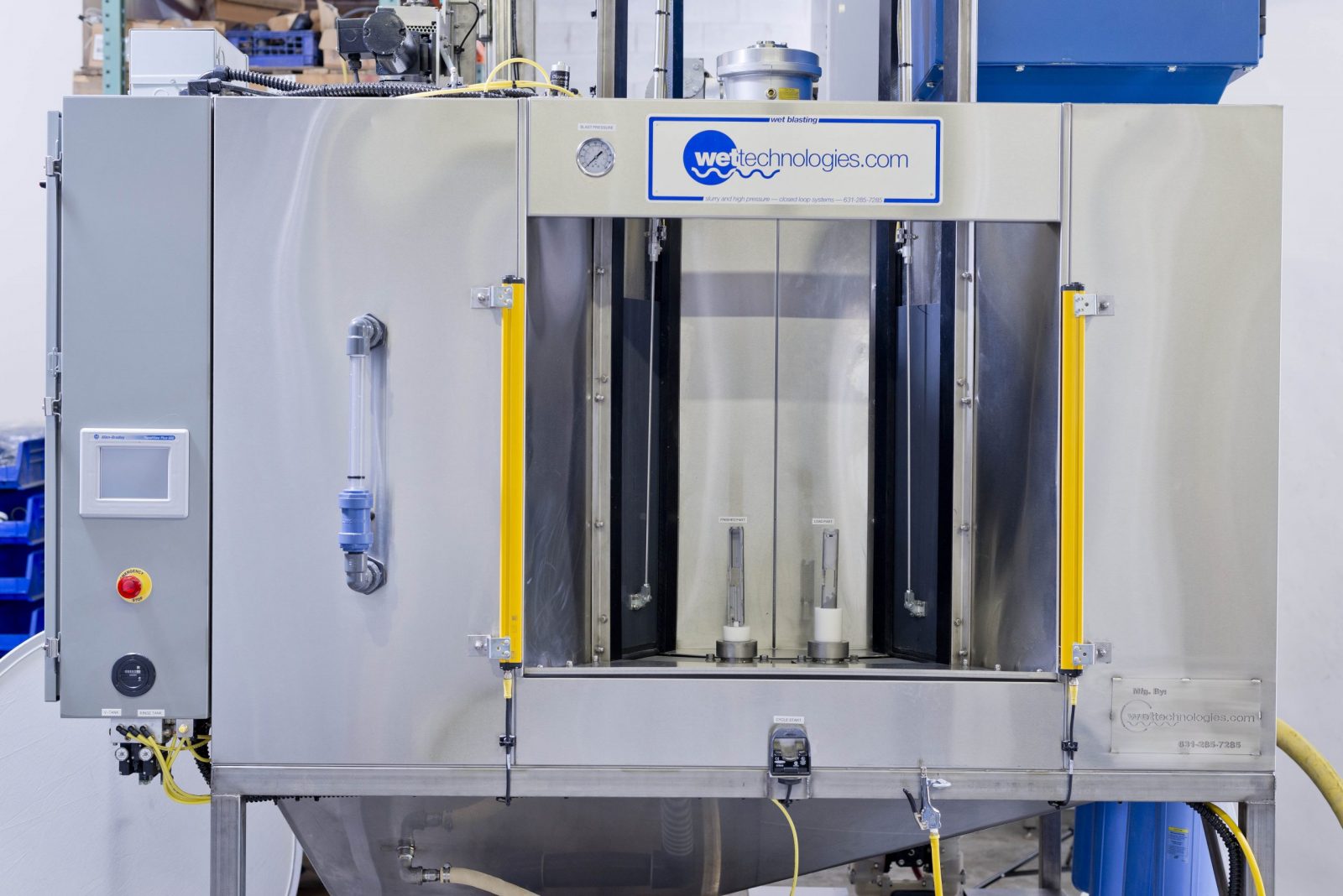

Automated Wet Blasting Equipment

Automated Wet Blast Systems are ideal for high capacity requirements that demand volume, speed, consistency, and ease of utilization.

Wet Technologies engineers automated wet blasting equipment that satisfies these needs. Innovations such as dual load doors and power drives enable one part to be processed while others are loaded and unloaded. Let us consult with your team to see how we can further customize your production.

Automated Wet blasting creates smooth and precise finishes while reducing abrasive embedment. Wet blasting eliminates dust problems associated with traditional blast cabinets, while preserving the abrasive longer than traditional dry blasting.

Have A Question?

Contact us today to talk to a LIVE representative. We can answer your questions, set up a site visit, or work out details for a trial of our products! Our team of technically trained sales representatives are backed by years of industrial knowledge and practice to help develop the best processes for your applications.