Aqueous Parts Washer

Aqueous parts washer systems use heated recirculated water with cleaning chemistry and a variety of blowoff systems to effectively clean and dry parts. Standard features on these systems typically include adjustable locking swivel spray nozzles, adjustable air knives, and a stainless steel body.

This technology along with many other unique features and options can generate significant savings on overall production.

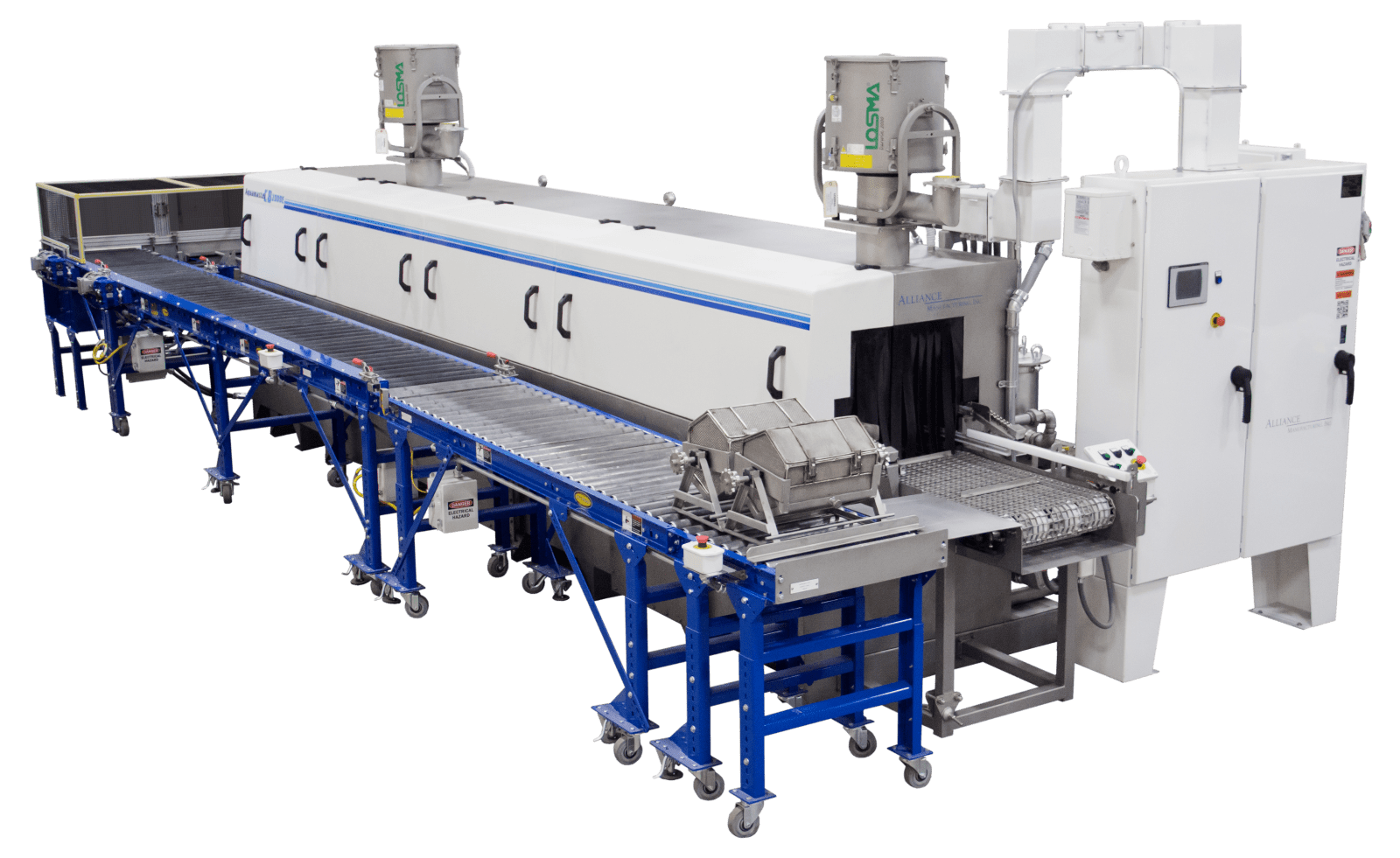

Conveyor Parts Washer

Conveyor industrial parts washers provide effective cleaning for many industrial applications and can be used on an in-line system.

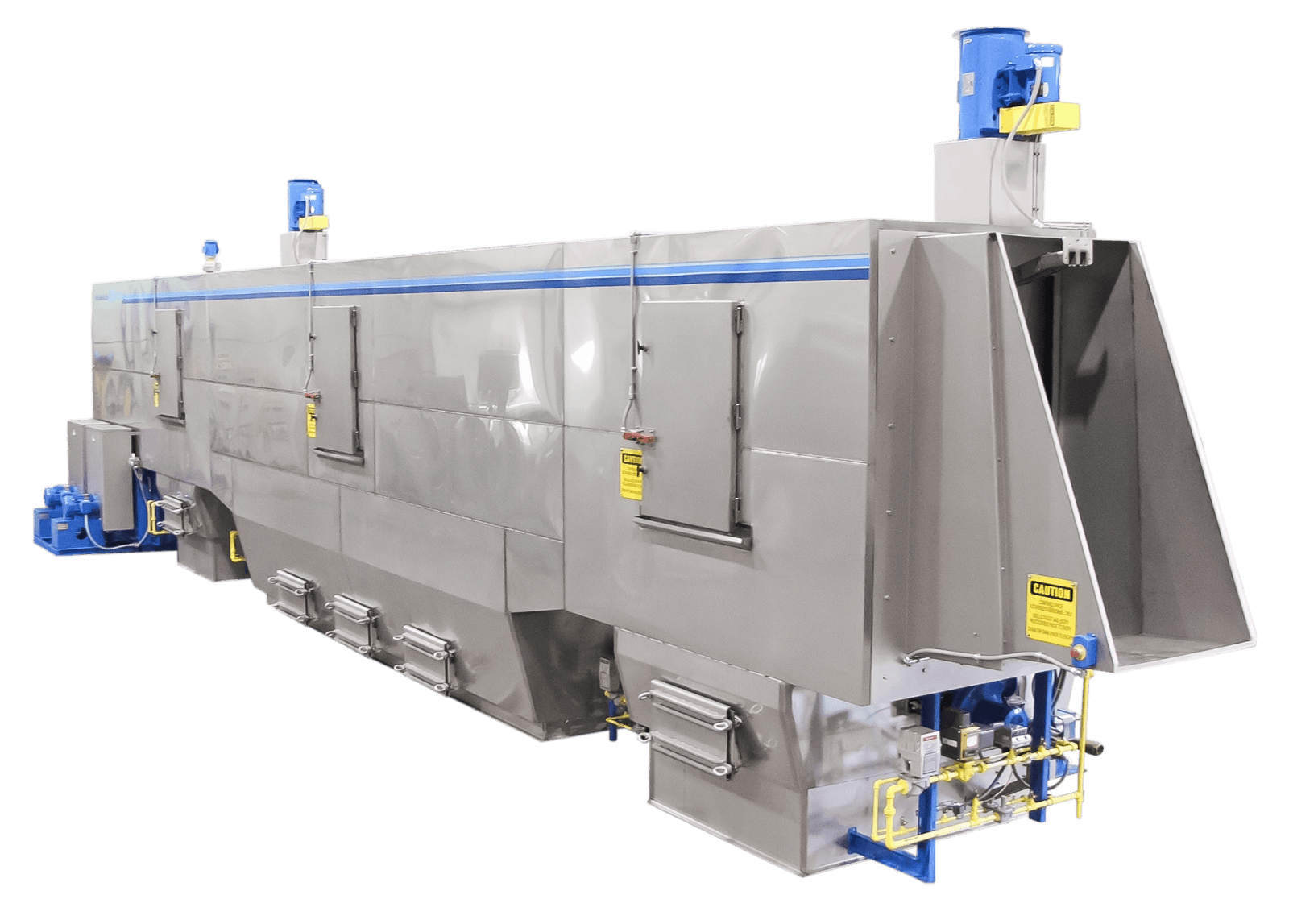

Monorail Parts Washer

Monorail parts washers provide effective cleaning for large, hanging pieces on an in-line system.

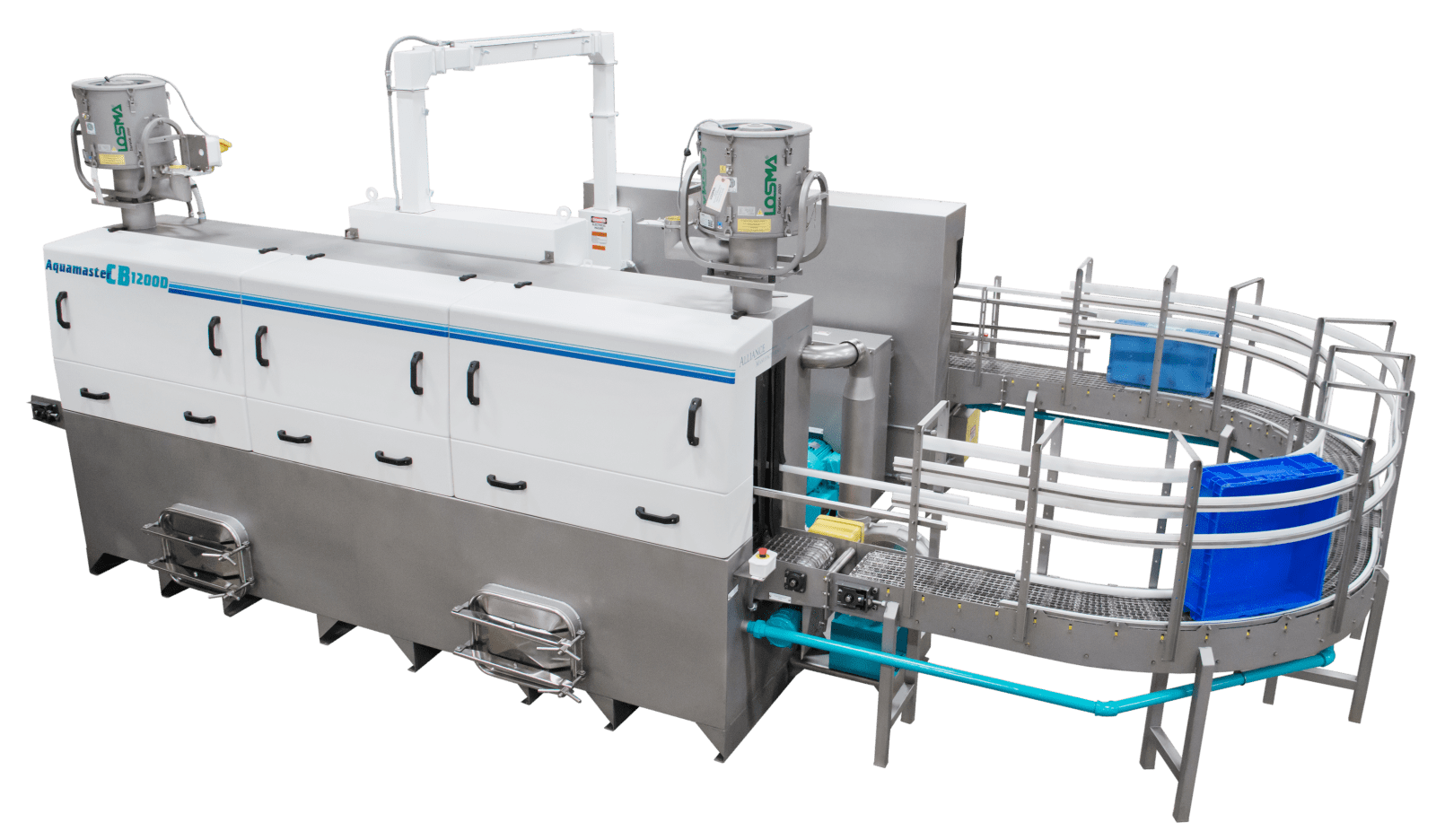

Dunnage Parts Washer

Dunnage Parts Washers provide parts cleaning and drying for industrial plastics including crates, trays, barrels and more.

Cabinet Parts Washer

Cabinet Parts Washers have a small footprint and provide a cost-effective solution to your parts cleaning needs.

Agitation Parts Washer

Agitation parts washers use a full immersion process along with cleaning chemistry to provide a general cleaning application.

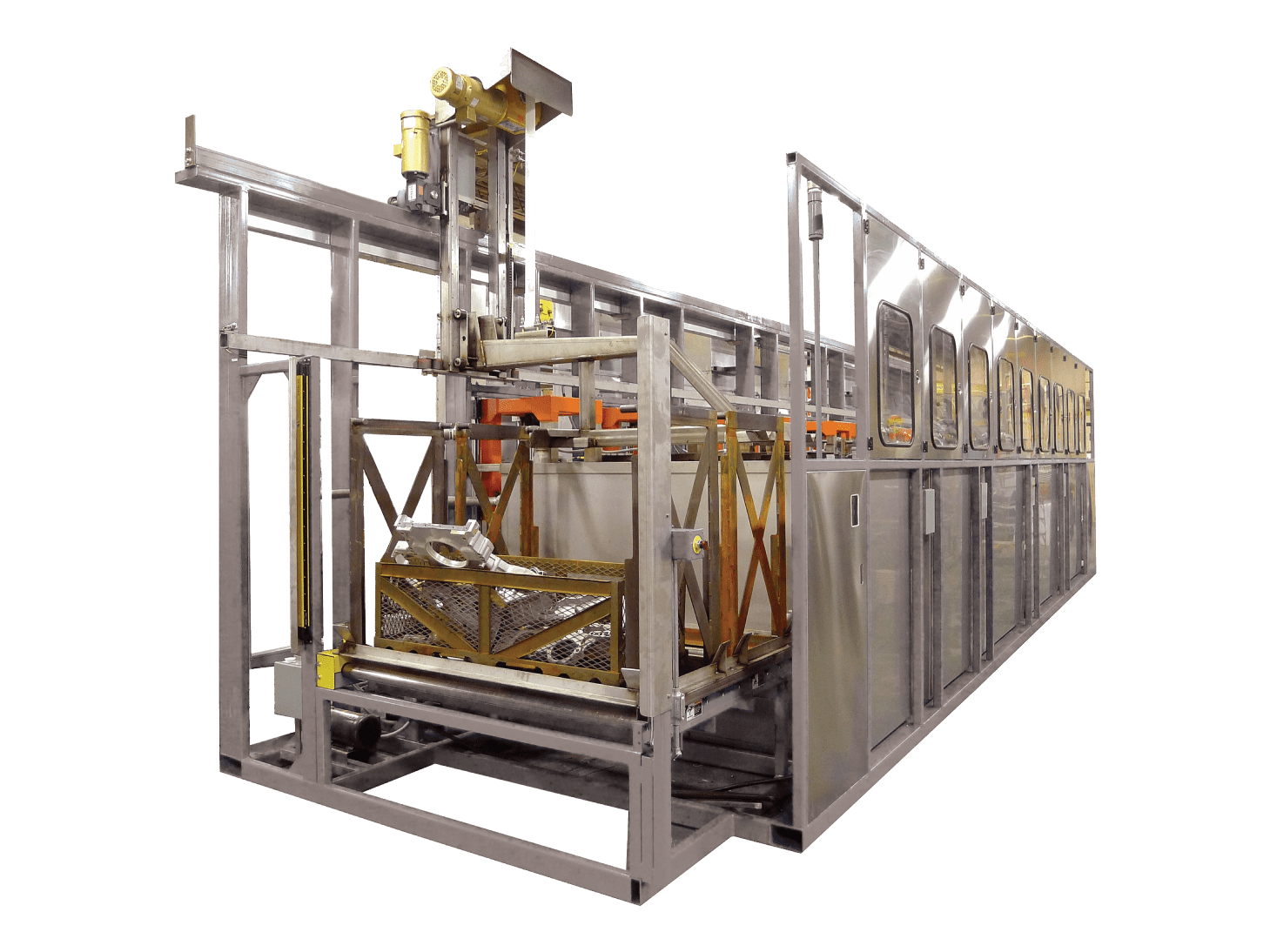

Hoist Parts Washer System

Hoist Parts Washer Systems utilizes a mechanical hoist to raise and lower large and heavy parts into the cleaning equipment.

Rotary Basket Parts Washer

Rotary basket parts washers are ideal for batch feed parts washing with continuous feeding from various machines.

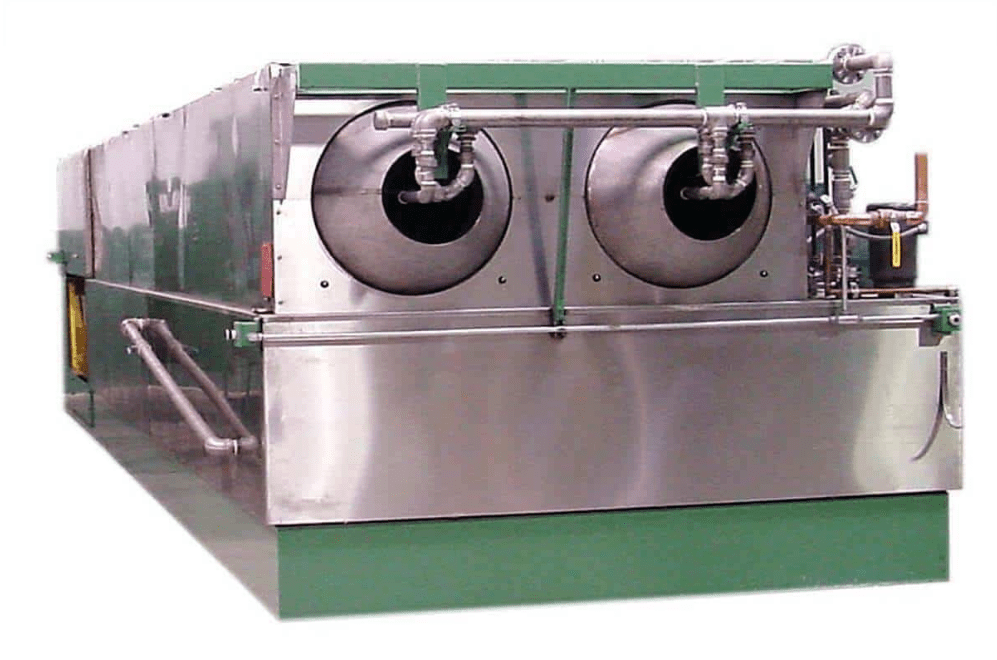

Rotary Drum Parts Washer

Rotary drum parts washers are ideal for batch feed or in line parts washing with continuous feeding from various machines.

Providing Consistent Cleaning Finishes

We offer an extensive lab to run parts tests and chemistry analysis to be certain you are using the best application for your parts and requirements.

Parts Washers Designed For Your Application

Our team of engineers will create a parts cleaning process designed for your applicaiton needs. Taking into consideration the part shape, cleanliness needs, chemistry and production rates. Contact us today to start the process