Plastic Tumbling Media

Plastic Tumbling Media

Plastic tumbling media is a lightweight media that reduces the chance of damaging sensitive parts with delicate surfaces. Plastic media comes in a variety of formulations (some are designed for use in high energy finishers or centrifugal barrels) to achieve finishes ranging from a clean and reflective finish to a smooth matte finish.

Finishing Applications for Plastic Tumbling Media

Mass finishing, deburring, deflashing, metal removal, and fine finishing.

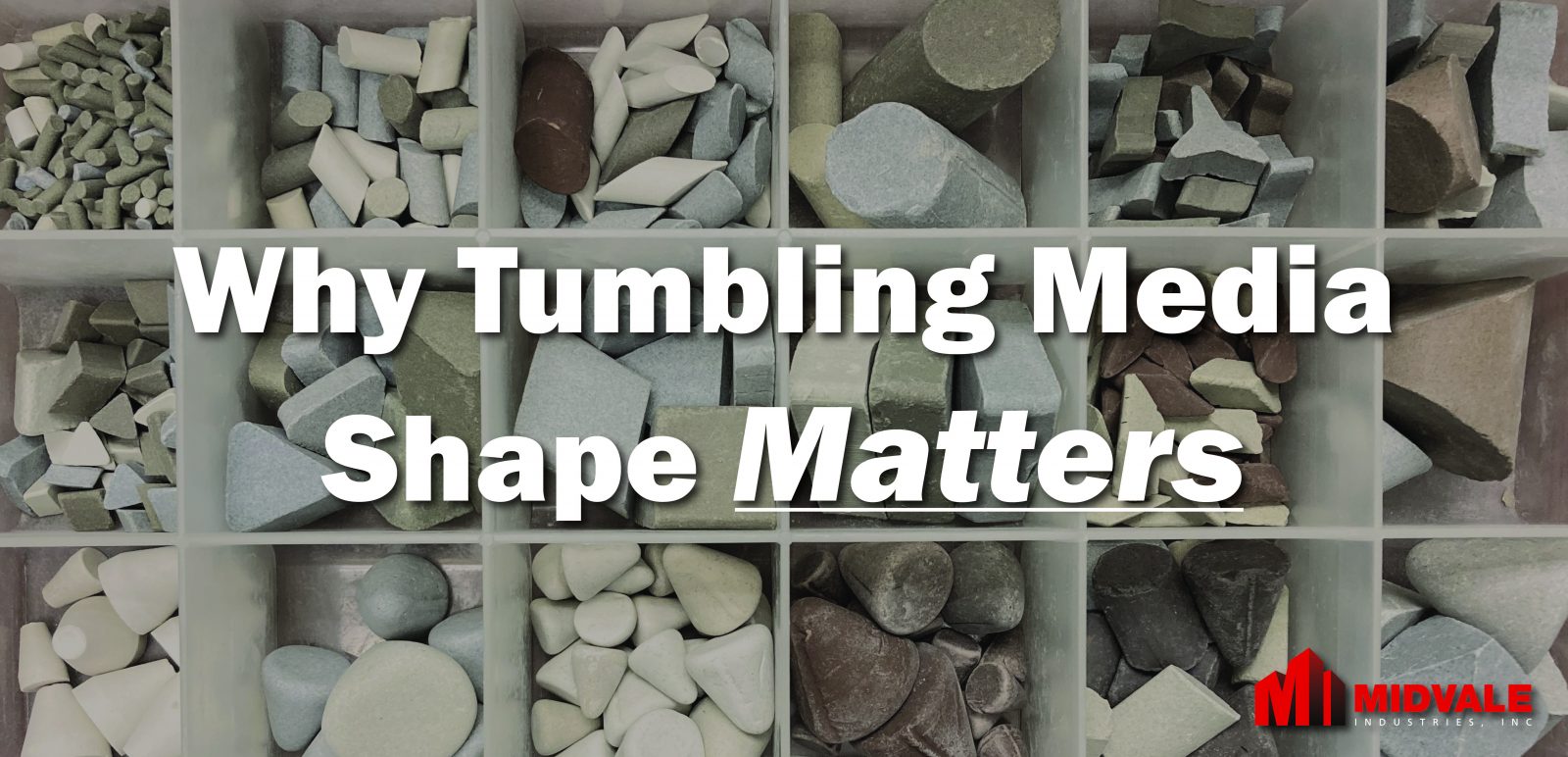

Shape & Size Options:

Standard shapes & sizes available, including but not limited to:

- Triangles, angle cut triangles

- Cones

- Cylindrical, pilgrim, round top, taper top

- Pyramids

- Stars

- Ellipses

- Wedges

Contact our team for special shapes and sizes.

Plastic Vibratory Media Composition Options:

- Low Density – designed for versatility, often used for deburring, flash removal, burnishing and preplate finishing.

- High Density – designed for superior cut and stock removal on both ferrous and non-ferrous metals. In most instances this high density media reduces cycle times and provides vastly improved finishes in applications ranging from deburring of hard metals to fine finishes on intricate parts.

- High Performance – formulated for use in specific applications involving ferrous metals. This media will provide a dramatic improvement in surface finishes with the impact resistance of a plastic body, which significantly decreases fracturing and impingement.

Each type of cutting ability has many composition formulas available. Contact our team for special compositions.

Considerations for Selecting Tumbling Media

Selecting the right tumbling media for your finishing applications is a vital step in the process of producing quality parts. Check out the articles below to learn about important considerations in the decision process. Click on the images to read the articles.

Schedule Your Vibratory Tumbler Media Trial

Contact our team to identify which vibratory media option will be best for your metal finishing process. Through our lab process, we can develop the best process for you and set up a trial.