Air Blast Equipment

Abrasive Blasting Equipment

Midvale carries a diverse selection of air blast equipment that will provide the best outcome for your application. We offer systems by Clemco Industries, Empire Abrasive Equipment, and Schmidt Abrasive. Air blast equipment is available in many sizes with numerous options to suit about any application or budget. View our selection of air blast equipment ranging from manual blast cabinets to full robotic blasting equipment.

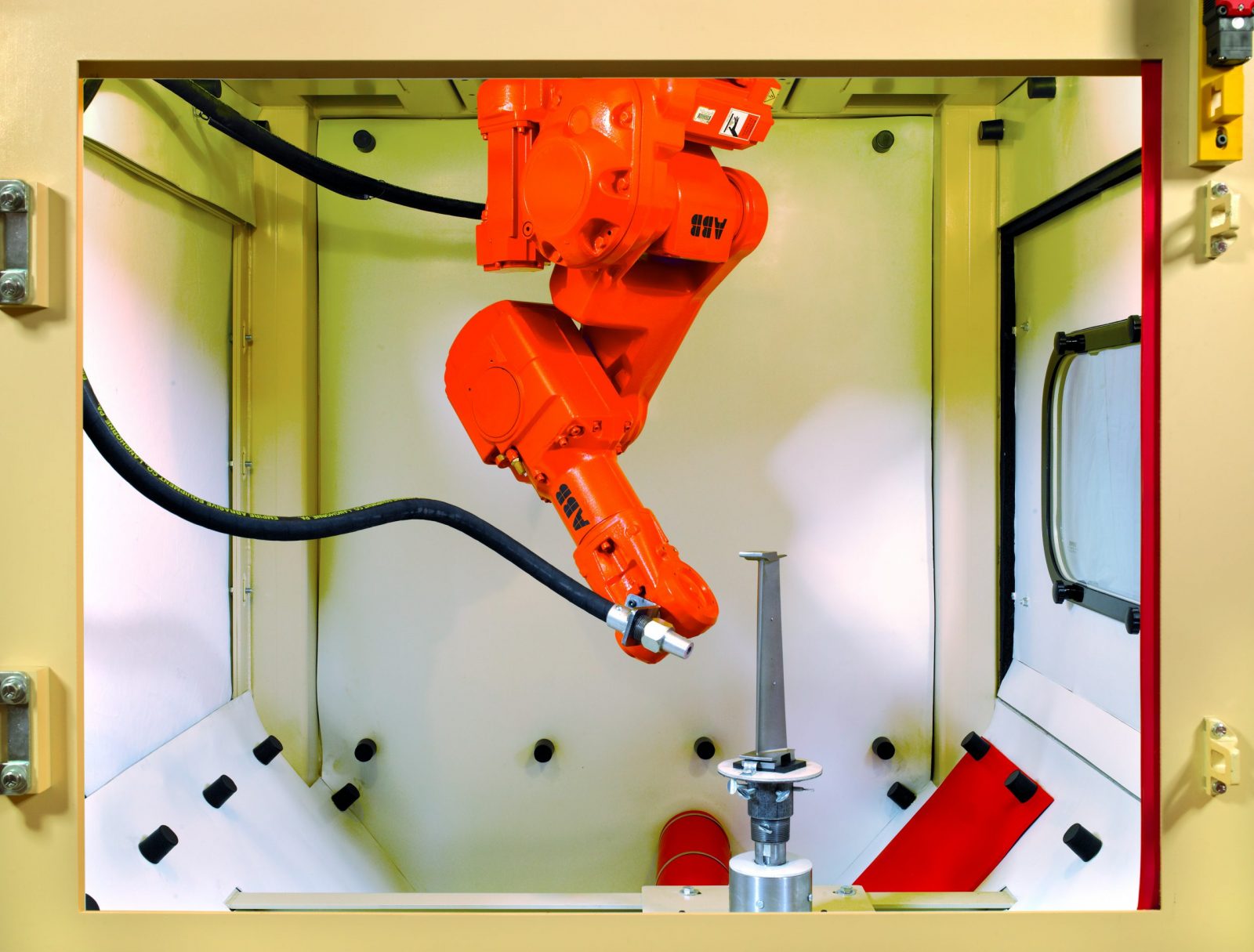

Robotic & Automated Air Blast Equipment

Robotic blast systems are custom designed for precision blasting applications, repeatability, and consistency.

Modified Blast Cabinet

Modified blast cabinets use a re-engineering process to meet your blasting process requirements that is more economical than full automation.

Manual Blast Cabinet

Abrasive blast cabinets provide a closed loop blast system that can hold different sized and shaped parts, providing diverse blasting capabilities.

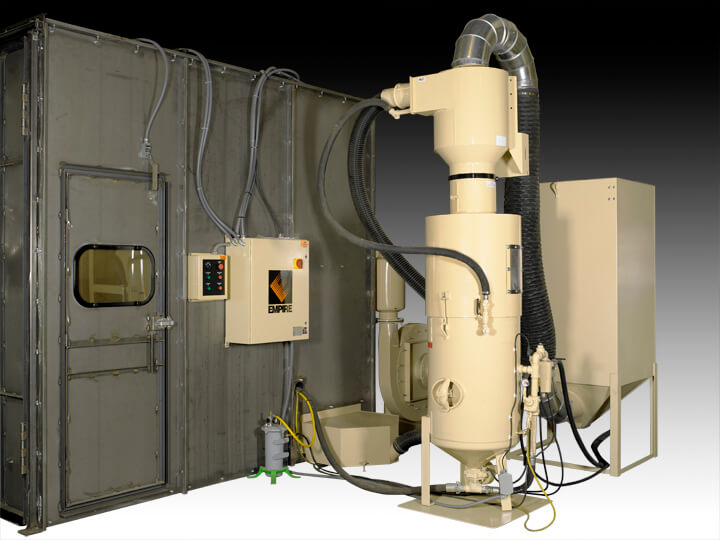

Industrial Blasting Room

Industrial blast rooms are used when equipment or parts become too large to fit into a standard blast cabinet.

Abrasive Blast & Recovery Systems

Abrasive blast & recovery systems save money by reclaiming and reusing recyclable media.

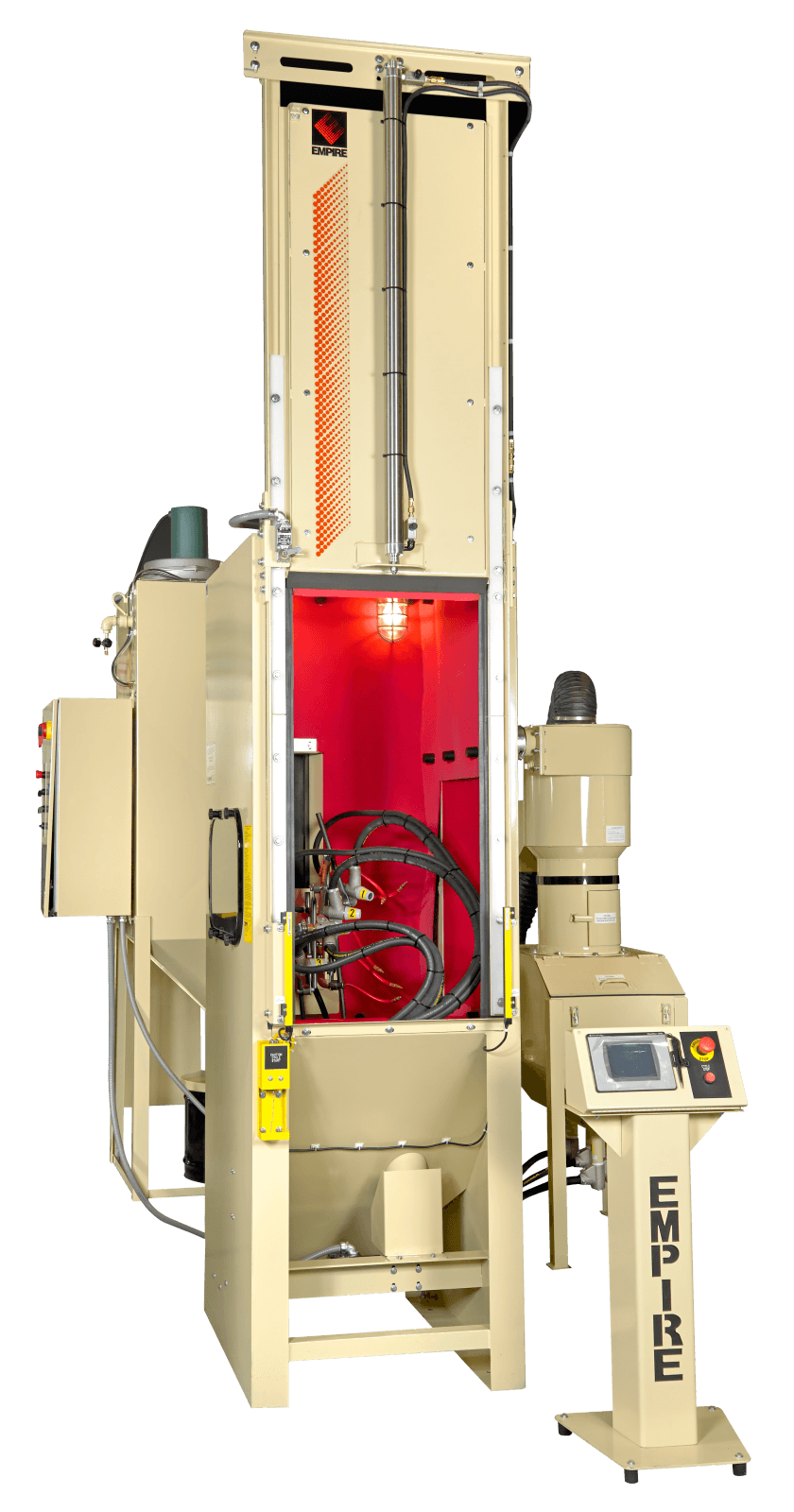

Cellular Blast Cabinet

Cellular Blast Cabinets conserve floor space and fit into your cellular machining process while providing the highest quality finish for your parts.

Sandblasting Pots

Sandblasting pots come in various configurations from portable blast systems for outdoors to systems designed for use with blast cabinets and rooms.

Bulk Blast Machine

Bulk blast machines are high-capacity blast pots, ideal for large blasting operations. These machines can be stationary within a facility or trailer mounted.

Soda Blasting Equipment

Soda blasting equipment has been specially designed for blasting lightweight abrasives such as baking soda.

Two Main Types of Air Blast Equipment Systems:

Pressure Blast Equipment

Pressure Cabinets hold the media in a pressurized vessel and meter the media into a flow of compressed air. The media is processed in a single, heavy-gauge hose where the blast particles are accelerated throughout its length.

Advantages of Pressure Blast Cabinets:

Greater media velocity

Moves more media

More productive

Greater standoff distance

Disadvantages of Pressure Blast Cabinet:

Higher capital equipment costs

Higher maintenance costs

Suction Blast Equipment

Suction blast cabinets are distinguished by having two hoses (one for air and one for abrasive) running to the blast gun. Utilizing air pressure, a suction gun pulls the media from a hopper through the hose for blasting.

Advantages of Suction Blast Cabinet:

Lower capital equipment cost

Easier maintenance

Less air and abrasive demand

Continuous blasting

Disadvantages of Suction Blast Cabinet:

Frequent Media Changes

Limited Repeatability

Engineered Process Development

Our team of technically trained staff will work with you to test and develop the best process for your blasting application. We will test and suggest which media, blast nozzle, type of equipment, blasting pressure, stand-off distance and blast angle to use to provide the desired surface finish.

We treat each blasting operation as a unique opportunity.

Let our team help engineer the best solution for you!