Foundry Supplies

From Furnane to Finish, Your Trusted Partner for Metalcasting Equipment, Supplies, and Service

Midvale Industries has specialized in Foundry Equipment and Supplies since 1901. We provide quality service and knowledge with all things metalcasting. Our goal is to work alongside you to develop a plan to produce high quality castings at a low cost.

Melt Department

Ensure you’re created quality castings by pouring the best melt with our foundry supplies.

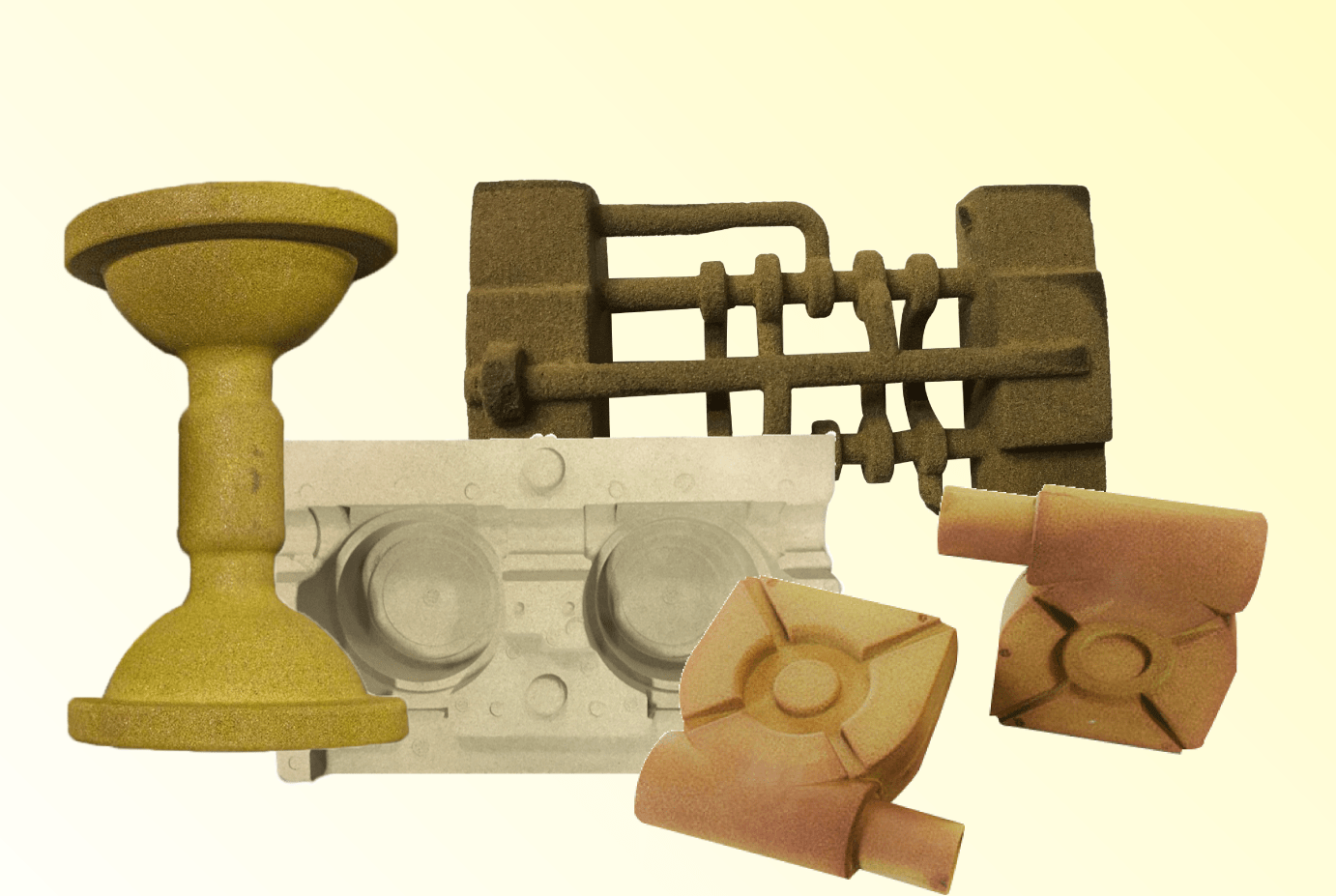

Mold & Core Making

Full line of mold and core making supplies such as sand, binders, additives and more.

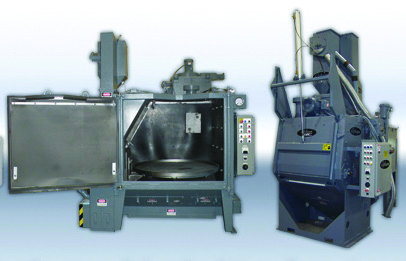

Cleaning Room

We provide the highest quality blast equipment and abrasives to clean the dirtiest castings.

Die Casting

Everything you need in your diecasting facility to produce quality castings with a great finish.

Foundry Ladles

Foundry ladles for multiple metal pouring and transfer applications, custom ladles and ladle parts.

Industrial Vacuums

Industrial vacuum systems provide a clean and safe working environment while maintaining OSHA regulations.

Personal Safety Equipment

We provide respirator hoods for radiant heat protection, grinding, and welding applications.

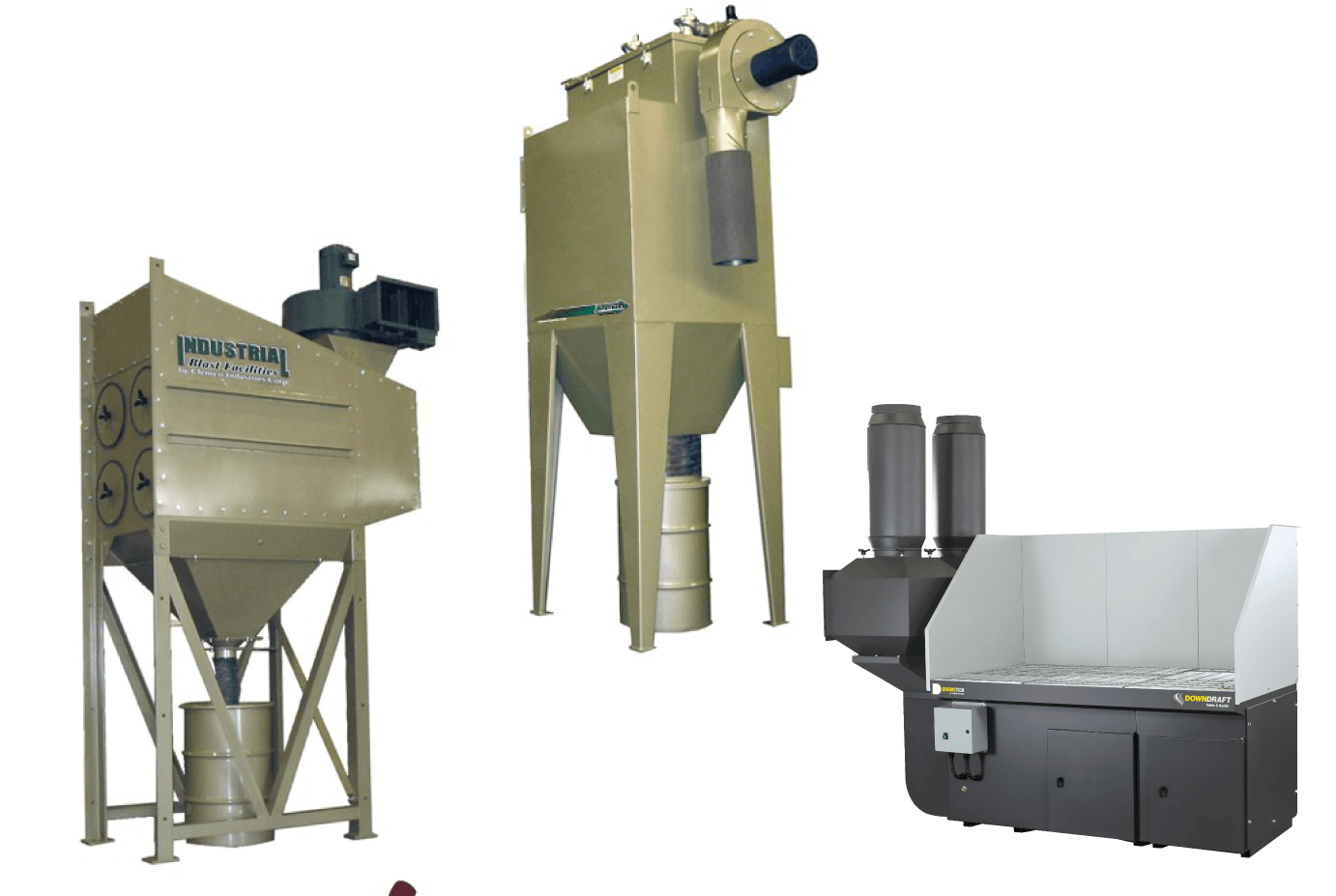

Dust Collection

Maintain safe air quality to improve your work environment for your employees.

Eliminate Silica Exposure In Your Foundry

One of our main values is the health & safety of people. We want to provide safe processes and remove hazard from the work place. Crystalline silica is commonly foundry in many foundry sands. We offer silica free mold & core sands for foundry applications to promote a cleaner work environment.

Midvale Freedom Foundry Products

Midvale has developed a line of custom foundry products called Freedom Products which includes all of the products you need to create a perfect casting. Products include Pumpable Mold Sealer, Nozzle Cement, Core and Mold Coatings, Anti-Veining Agents, Core Sand Additives, Parting and Release Agents, Mudding Compounds and Core Pastes, Riser Aids, and more.

Improve Your Casting Finish

We can help reduce finishing costs by improving your melt, mold and core processes. Talk to our team today to find out about our high quality materials.

Proud Corporate Member of the following Foundry Associations: