Aerospace Coating Removal

Aerospace Coating Removal

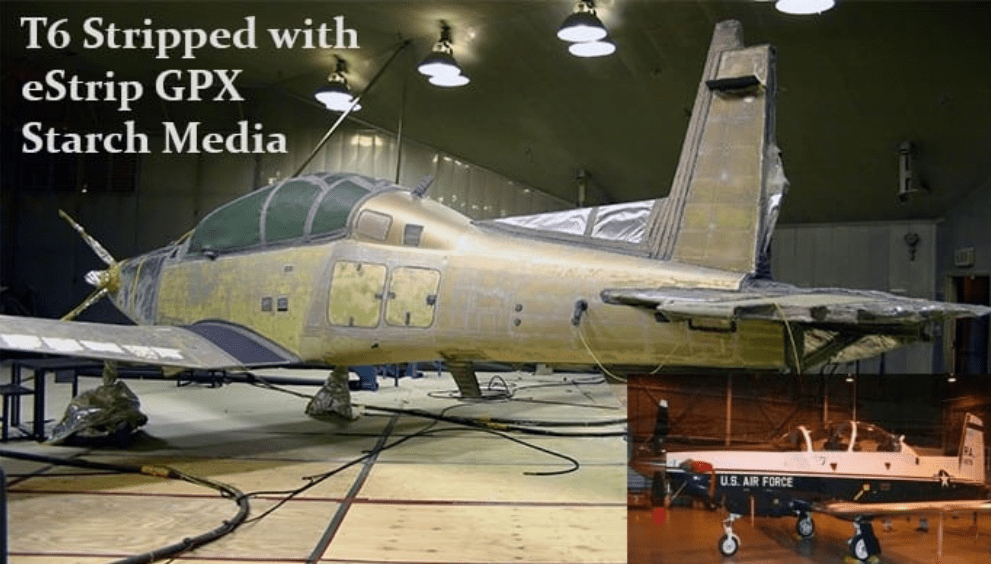

Our starch abrasives are designed to remove tough aircraft coatings without damaging the most sensitive substrates. Archer Daniels Midland’s (ADM ®) EnviroStrip ®, EnviroStrip®XL and eStrip® GPX Type VII plastic dry stripping media protects sensitive surfaces such as thin skinned aluminum, carbon fiber, and composites against damage during dry stripping.

Biobased abrasives have a self-sharpening crystalline structure that insures consistent cutting capability throughout the product’s life. These abrasives are less damaging and longer lasting compared to traditional plastic media blasting (pmb) abrasives.

Key Benefits of Bio-Based Abrasives

- Ideal for thin skinned aluminum, composite flight controls, airframes, blades, and more

- Bio-based starch media is less damaging than traditional PMB Blasting

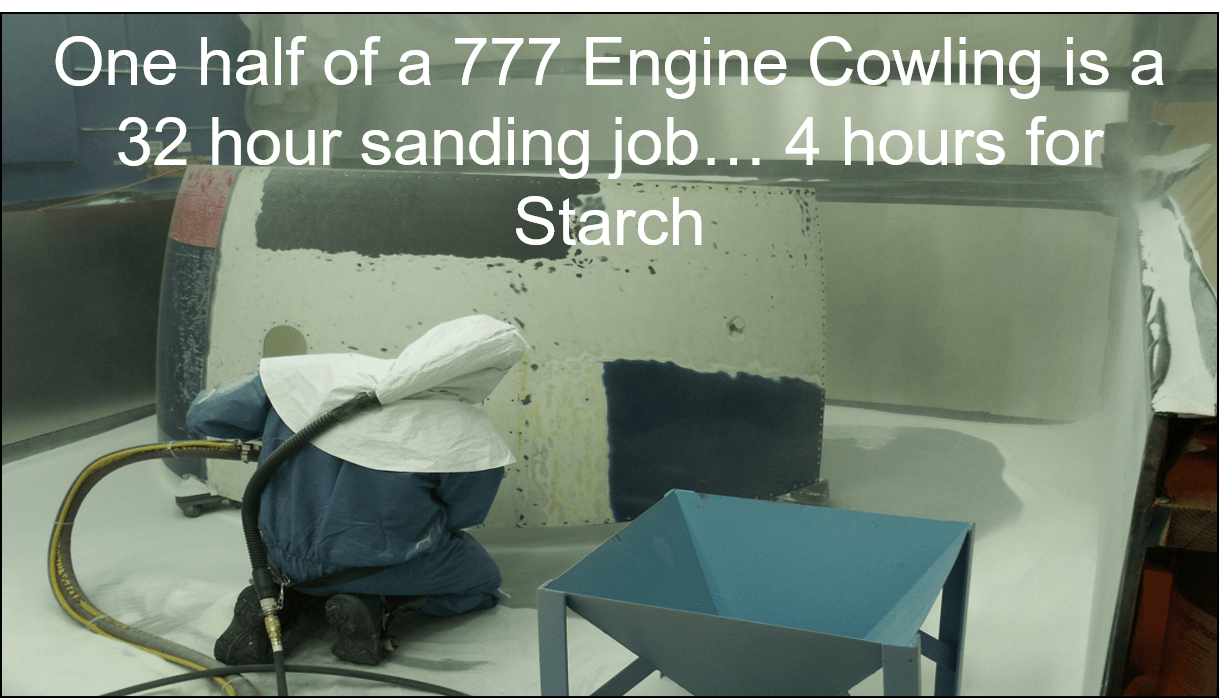

- Starch abrasives remove coatings 8 to 10 times faster than hand sanding

- Reduces hazardous waste and disposal costs

- Midvale’s mobile demo lab is fully equipped with a blast room for testing, processing sample parts and training staff on using starch abrasives at your facility

Starch Blast Media Details:

- eStrip media is classified as USAF Type VII starch-g-acrylic media and is manufactured to meet the USAF MIL-P-85891 requirement

- Enables adhesive squeeze out removal from metal to metal, metal to composite and composite to composite

- Replaces traditional methods, including chemical stripping and machine hand sanding

- Established record of success with composite tool and mold cleaning applications

- State and EPA Approved Recycling and Continuous Use Programs exist throughout the country

- Starch is a renewable resource product

- Midvale Environmental Technologies has been recognized along with the U.S. Coast Guard’s Aircraft and Supply Center for eliminating their blasting facilities hazardous waste and reducing disposal costs

Eliminate Hand Sanding

Handsanding aircraft and structures is not only a timely process, but dangerous to the substrate. Converting to starch abrasive not only improves overall process time, but also extends the life of the aircraft. Thr ROI on this conversion will be seen for years in both time and money.

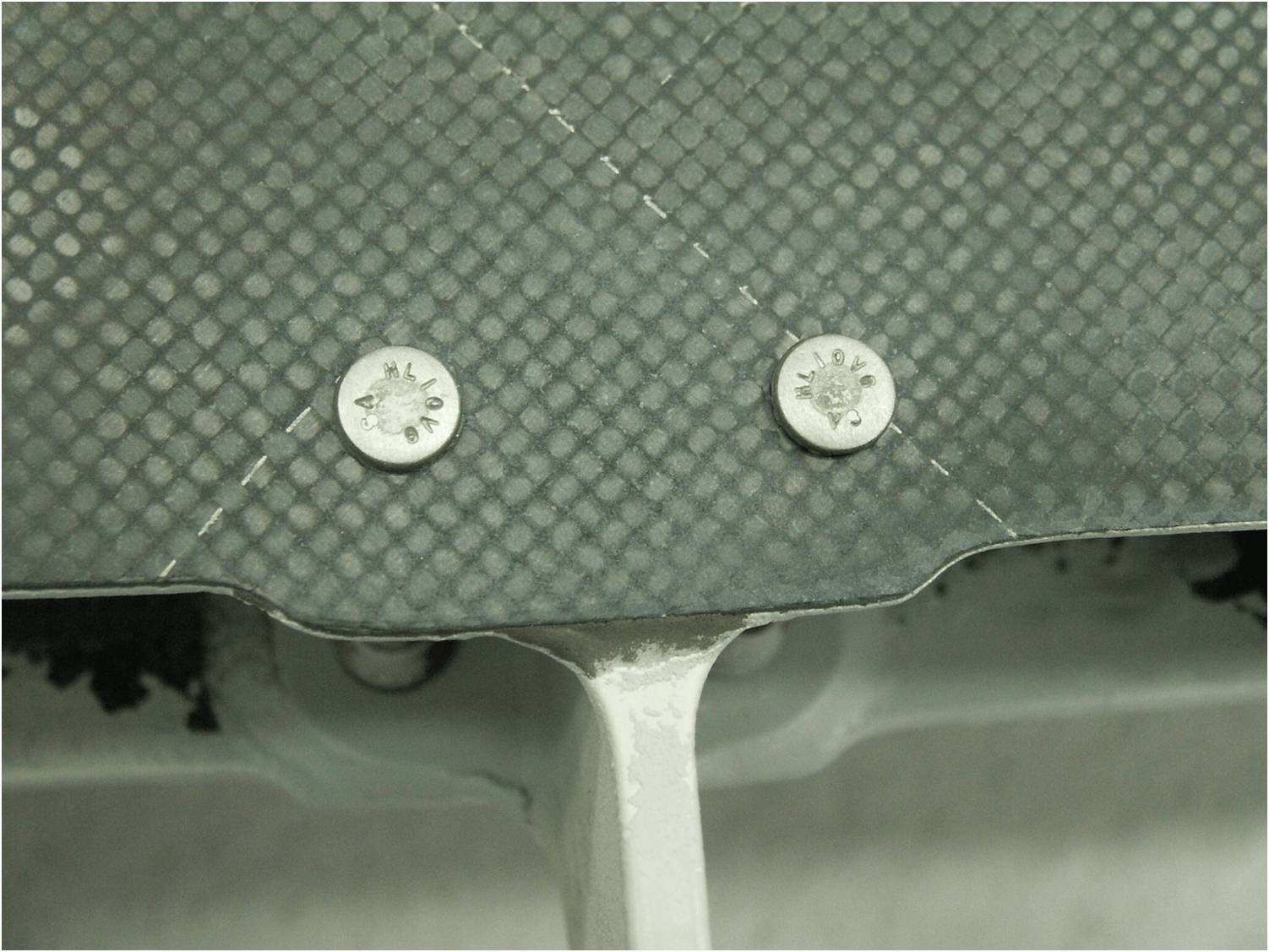

Handsanding Rivet Damage

Have A Question?

Contact us today to talk to a REAL representative. We can answer your questions, set up a site visit, or work out the details for a trial of one of our products! Our team of technically trained sales representatives are backed by years of industrial knowledge and can help develop the best process for your applications.