Foundry Coatings

Foundry Coatings

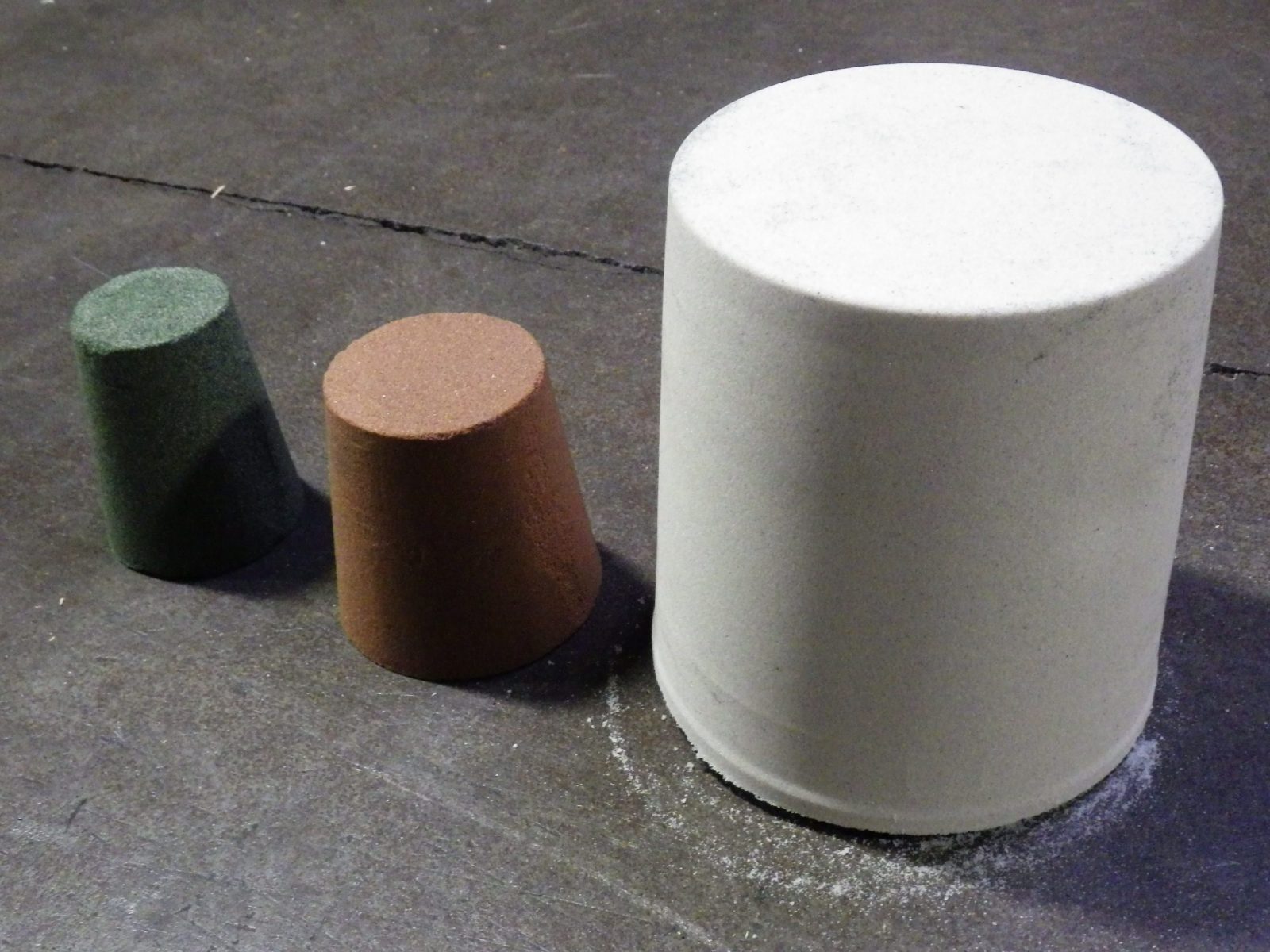

Freedom foundry coatings for molds and cores are versatile, competitively priced (also weigh less per gallon), and cover without running. Coatings can be applied in multiple ways including flow coating, spraying, dipping, or painting.

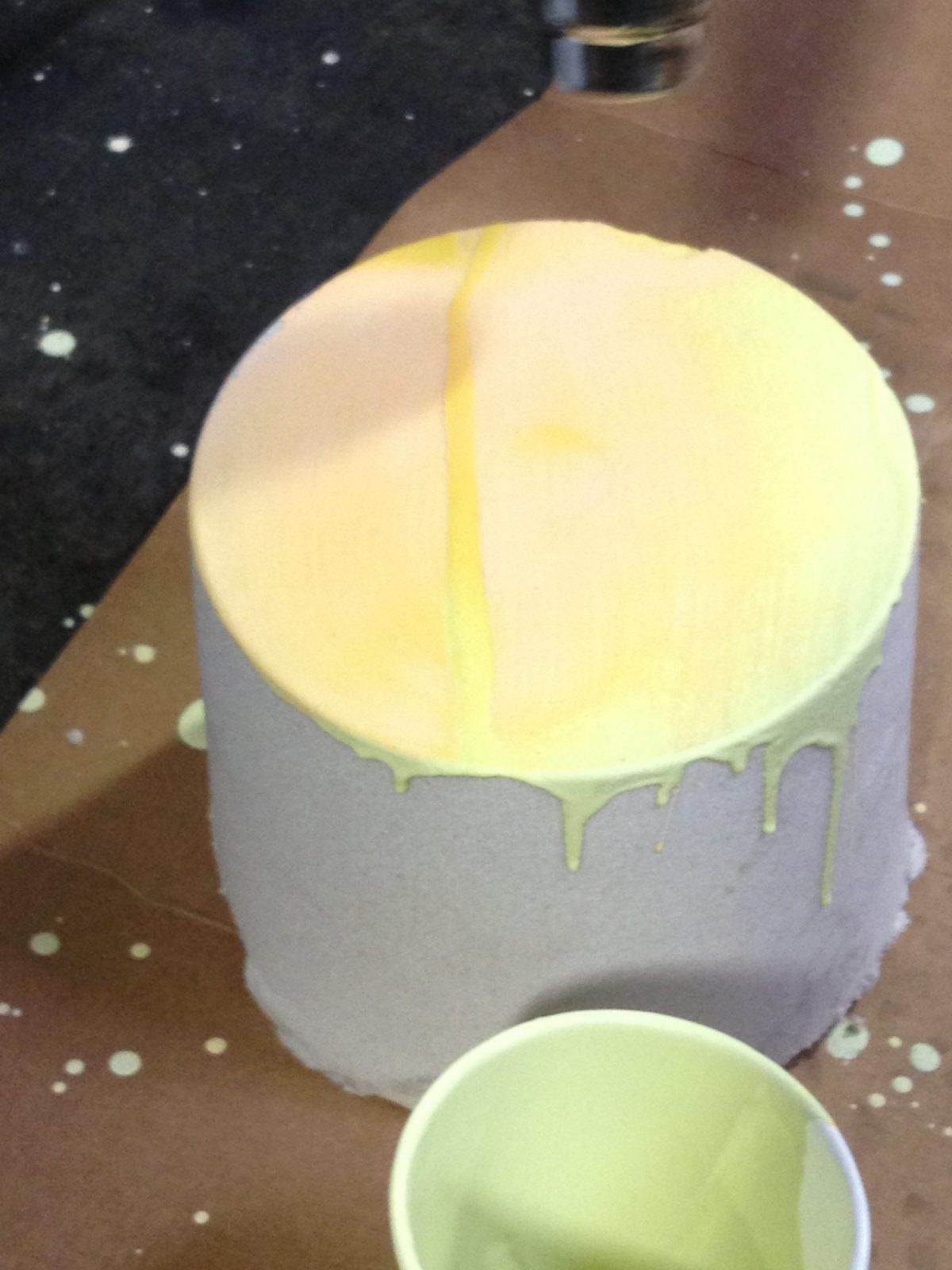

Freedom Coatings come in both water and solvent carriers and can be used for all types of refractories. Cerabead coating is also available as a replacement to zircon. Freedom Coatings improve casting quality, decrease scrap and cleaning times, and reduce the cost of coating. Water-Based Coatings are available with color change technology to let foundry staff know when coating has dried.

- Freedom Foundry Coatings are offered in both water and solvent carriers, for all types of refractories, and also in a blend of refractories

- Freedom Foundry Coatings can be flow coated, sprayed, dipped or painted

- Water-Based Coating are available with color changing technology letting the operator when the coating has fully dried

Have A Question?

Contact us today to talk to a LIVE representative. We can answer your questions, set up a site visit, or work out details for a trial of our products! Our team of technically trained sales representatives are backed by years of industrial knowledge and practice to help develop the best processes for your applications.