https://midvaleindustries.com/wp-content/uploads/2024/08/Pressure-vs-Suction-Large.jpg

1260

2240

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2024-04-29 16:11:322026-03-04 09:13:23Difference Between Pressure vs Suction Blast Cabinet

https://midvaleindustries.com/wp-content/uploads/2024/08/Pressure-vs-Suction-Large.jpg

1260

2240

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2024-04-29 16:11:322026-03-04 09:13:23Difference Between Pressure vs Suction Blast CabinetEvery project requires a it’s own blasting process, equipment and media selection, but here are a few general sandblasting tips to help guide you in the process.

1.) Never Blast With Silica Sand

Besides new stricter laws addressing Silica PEL Limits, crystaline silica leads to a deadly disease known as silicosis. Never use silica sand (also known river sand and sugar sand) for abrasive blasting. Consider using other low cost alternatives such as Black Beauty Coal Slag, Green Diamond Sand, Starblast

2.) Reclaim Your Media

If you want to save money, find a way to reclaim your media. There are several ways to reclaim media, one way is to use a blast cabinet or blast room with a reclamation system. In open blasting situations outdoors pneumatic blast and recovery systems are a great option as well as blast and vac systems.

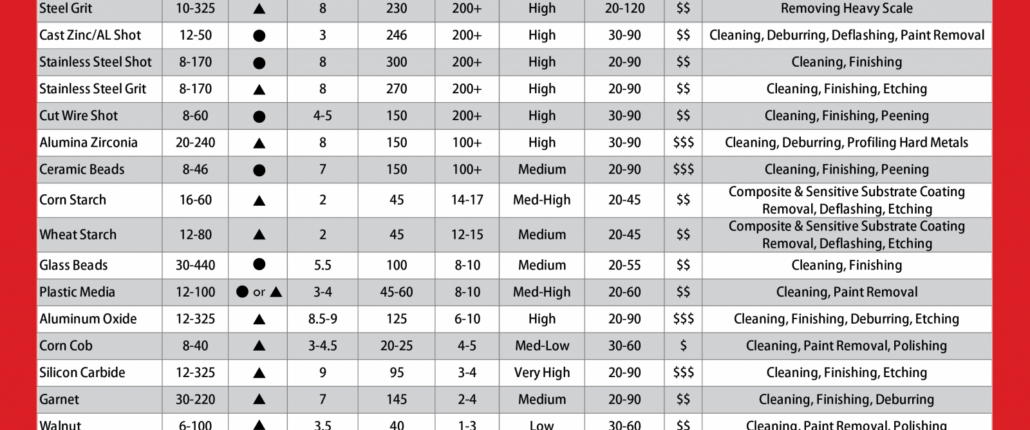

3.) Choosing A Blasting Abrasive

Selecting your blast media is an important part of the overall process. You need to ensure that the media is safe to use on your substrate, whether or not you can reclaim and recycle, and the desired outcome. Ask your media supplier for an estimate on blast bycles for the media you think will fit best. (See Below)

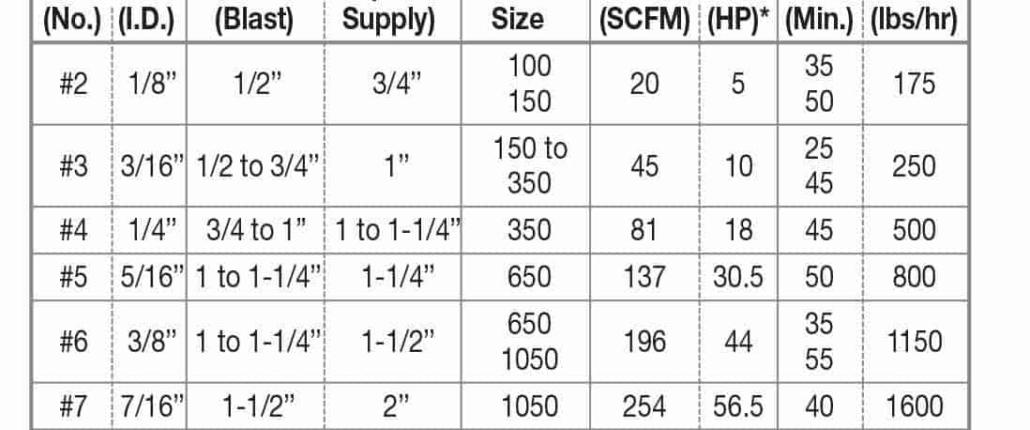

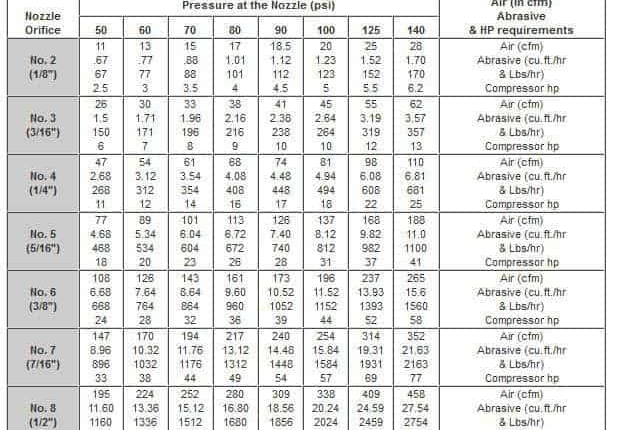

4.) Make Sure You Are Using The Right Sized Compressor For Your Nozzle

Larger Blast Nozzle typically equals more production, that being said it also requires more CFM and Horsepower from your compressor. The chart above illustrates what is required from compressor based on nozzle and pressure at the nozzle. Tip: It is a good practice to base your compressor size requirements based on the next nozzle size up, to accommodate for nozzle wear especially when blasting with aggressive media.

There are several types of blast nozzles to choose from. They very in size, shape and material.

Choosing the correct size and type of blast hose will not only ensure a longer life of the hose based ont he type of media you are using, but will also help reduce operator fatigue. Ensuring your operators are working at the highest level will increase production and efficiency. There are several types of blast hose to choose from, some factors to consider include weight, durability, flexibility, and is it static dissipating.

5.) Choose The Correct Blast Hose

If you are not sure what personal protection equipment you should wear when abrasive blasting, contact your media supplier or you can call reach out to a Midvale Technical Rep. Typical protective equipment includes a blast helmet, blast helmet lenses, blast suit and cape, blast gloves, air supply line, breathing air hose, CO monitor, CPF Filter, and sometimes an ambient air pump.

6.) Wear Proper PPE With Protective Clothing

7.) Cheap Abrasives May Not Be That Cheap

There are a number of factors that determine the “true cost” of an abrasive: The dollar amount per pound, the number of cycles, and your reclaim system.

As mentioned in tip number 3 reusability is important, blast media that initially seems very expensive such as steel shot/grit (reusability 200 cycles) versus a cheaper abrasive such as coal slag (reusability 1 – 3 cycles). While steel media is superior in reusability it is not cheaper if you cannot reclaim it effectively (see tip #2).

Interested in learning more about how to make your blasting operation efficient and productive? Or starting your blasting operation from the ground up? Talk to our team of technically trained reps today.

Share This Post

More Like This

https://midvaleindustries.com/wp-content/uploads/2024/08/Pressure-vs-Suction-Large.jpg

1260

2240

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2024-04-29 16:11:322026-03-04 09:13:23Difference Between Pressure vs Suction Blast Cabinet

https://midvaleindustries.com/wp-content/uploads/2024/08/Pressure-vs-Suction-Large.jpg

1260

2240

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2024-04-29 16:11:322026-03-04 09:13:23Difference Between Pressure vs Suction Blast Cabinet https://midvaleindustries.com/wp-content/uploads/2024/08/Maintenance-Blast-Tips-01-1-2.jpg

628

1200

Nate Riggins

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

Nate Riggins2022-11-16 17:01:552026-03-04 09:13:25Maintenance Tips for Abrasive Blasting

https://midvaleindustries.com/wp-content/uploads/2024/08/Maintenance-Blast-Tips-01-1-2.jpg

628

1200

Nate Riggins

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

Nate Riggins2022-11-16 17:01:552026-03-04 09:13:25Maintenance Tips for Abrasive Blasting https://midvaleindustries.com/wp-content/uploads/2024/08/wheel-blast-blod-header-text-2.png

900

1600

Nate Riggins

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

Nate Riggins2020-08-14 14:43:402026-03-04 09:13:298 Quick Tips for Extending the Life of Your Gibson Wheel Blast System

https://midvaleindustries.com/wp-content/uploads/2024/08/wheel-blast-blod-header-text-2.png

900

1600

Nate Riggins

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

Nate Riggins2020-08-14 14:43:402026-03-04 09:13:298 Quick Tips for Extending the Life of Your Gibson Wheel Blast System https://midvaleindustries.com/wp-content/uploads/2024/08/Blasting-Blog-Sept-2019-2.png

900

1600

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2020-03-18 19:02:192026-03-04 09:13:30How To Maintain An Efficient Blast Media Work Mix

https://midvaleindustries.com/wp-content/uploads/2024/08/Blasting-Blog-Sept-2019-2.png

900

1600

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2020-03-18 19:02:192026-03-04 09:13:30How To Maintain An Efficient Blast Media Work Mix https://midvaleindustries.com/wp-content/uploads/2024/08/Particle-Size-Matters-1-2.jpg

800

800

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2020-03-18 03:50:482026-03-04 09:13:30Why Particle Size Matters When Blasting

https://midvaleindustries.com/wp-content/uploads/2024/08/Particle-Size-Matters-1-2.jpg

800

800

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2020-03-18 03:50:482026-03-04 09:13:30Why Particle Size Matters When Blasting https://midvaleindustries.com/wp-content/uploads/2024/08/Adobe-Spark1-2.jpg

838

1600

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2020-03-18 03:21:172026-03-04 09:13:31Choosing The Correct Blast Hose Size

https://midvaleindustries.com/wp-content/uploads/2024/08/Adobe-Spark1-2.jpg

838

1600

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2020-03-18 03:21:172026-03-04 09:13:31Choosing The Correct Blast Hose Size