https://midvaleindustries.com/wp-content/uploads/2024/08/Pressure-vs-Suction-Large.jpg

1260

2240

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2024-04-29 16:11:322026-03-05 09:12:41Difference Between Pressure vs Suction Blast Cabinet

https://midvaleindustries.com/wp-content/uploads/2024/08/Pressure-vs-Suction-Large.jpg

1260

2240

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2024-04-29 16:11:322026-03-05 09:12:41Difference Between Pressure vs Suction Blast CabinetAbrasive blasting operations rely on equipment to complete the job. Ensuring the blast equipment is running efficiently and not breaking down is an important part of any blast operation. These maintenance tips will help keep your blasting operation running efficiently and limit any shutdowns.

Commonly Replaced Blast Parts

With the use of abrasives, metal components, seals and gaskets will start to wear down. Regular replacement of these part is important to ensure that equipment runs at peak performance, avoiding a potential job shutdown.

Here is a list of the most commonly replaced items on blast equipment:

- Pop-Up Valve Seat & Seal

- Grit Valve and its Components

- Exhaust Muffler

- Blast Hose

- Blast Nozzle

- Nozzle Holder

- Remote Control Handle and Hoses

- Remote Control Valve Kits

We have replacement blast parts in stock. View our blast parts here.

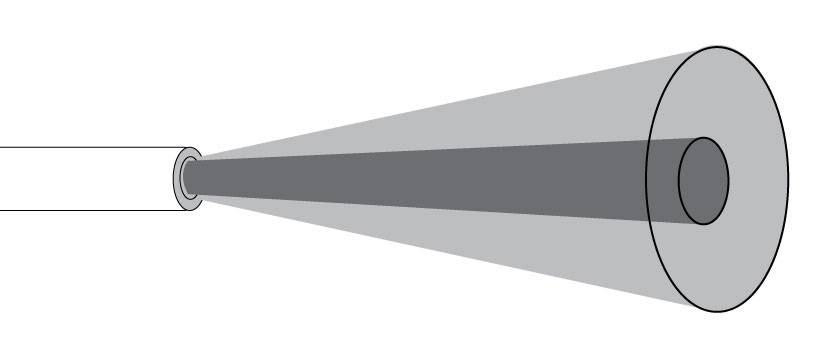

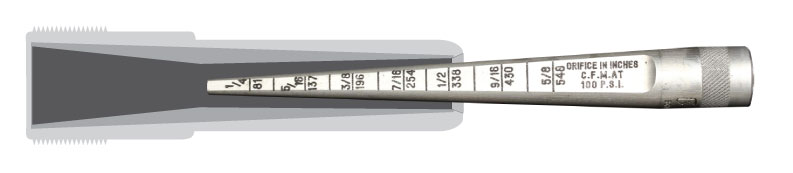

Negative Effects of Nozzle Wear

An abrasive blast nozzle naturally wears down with use. The type of nozzle material, blast media, air pressure, and work time all play a role in just how quickly this happens. Keeping a nozzle gauge handy will assist in monitoring the rate of wear on your nozzle to know when to replace it.

Negative effects of nozzle wear:

Increased Air Consumption

- Reduces the life of your compressor

- Increases energy use of maintenance costs

Irregular Blast Pattern

- This increases time (labor hours) spent on part(s) as the blast pattern is uneven and erratic.

- Inconsistent end product, lowering the quality of work

Commonly Replaced Safety & PPE Parts

Operator safety is a vital part of the abrasive blasting process. Blasting creates dust that can be dangerous when inhaled, as well as creates physical dangers by way of sharp pieces of media, high air pressures, and obstacles in the blast environment. There are components of the breathing air respirator and filter that need to be replaced regularly.

We carry safety equipment and replacement parts in stock. View our safety & PPE items here.

Here is a list of the most commonly replaced items on personal protection equipment:

- Tear Away Lenses

- Replacement Lens & Gasket

- Helmet Suspension

- Hygiene Pads

- Air Filter Cartridge

- Breathing Tube

Tips & Tools to Keep Up with Maintenance

Maintenance is about regular up-keep to equipment rather than just repairing equipment after it breaks down. Knowing the ins and outs of your operation is key to planning your maintenance, as there are many factors that affect the rate of wear.

Here are some tools you can utilize to help navigate your blast equipment maintenance:

- Grit Valve Selection – Selecting the appropriate grit valve and components to withstand the type of media used for the blasting application. Having the correct components will limit how quickly they wear down with use.

- Needle Gauge – Provides an accurate reading of air pressure at the nozzle to ensure you are blasting at the appropriate psi.

- Nozzle Gauge – Measures the inside diameter of the nozzle to check if the nozzle has worn down below the requirement for the blasting operation.

Maintenance and Repair Services

Through an experienced technician, Midvale offers maintenance and repair services on blast equipment. Contact our team about your equipment’s regular maintenance, repairs, and replacement parts.

Share This Post

More Like This

https://midvaleindustries.com/wp-content/uploads/2024/08/Pressure-vs-Suction-Large.jpg

1260

2240

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2024-04-29 16:11:322026-03-05 09:12:41Difference Between Pressure vs Suction Blast Cabinet

https://midvaleindustries.com/wp-content/uploads/2024/08/Pressure-vs-Suction-Large.jpg

1260

2240

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2024-04-29 16:11:322026-03-05 09:12:41Difference Between Pressure vs Suction Blast Cabinet https://midvaleindustries.com/wp-content/uploads/2024/08/Sandblasting-Header-2.jpg

900

1600

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2022-03-22 13:58:522026-03-05 09:12:437 Things You Should Be Doing When Sandblasting

https://midvaleindustries.com/wp-content/uploads/2024/08/Sandblasting-Header-2.jpg

900

1600

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2022-03-22 13:58:522026-03-05 09:12:437 Things You Should Be Doing When Sandblasting https://midvaleindustries.com/wp-content/uploads/2024/08/wheel-blast-blod-header-text-2.png

900

1600

Nate Riggins

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

Nate Riggins2020-08-14 14:43:402026-03-05 09:12:478 Quick Tips for Extending the Life of Your Gibson Wheel Blast System

https://midvaleindustries.com/wp-content/uploads/2024/08/wheel-blast-blod-header-text-2.png

900

1600

Nate Riggins

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

Nate Riggins2020-08-14 14:43:402026-03-05 09:12:478 Quick Tips for Extending the Life of Your Gibson Wheel Blast System https://midvaleindustries.com/wp-content/uploads/2024/08/Blasting-Blog-Sept-2019-2.png

900

1600

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2020-03-18 19:02:192026-03-05 09:12:47How To Maintain An Efficient Blast Media Work Mix

https://midvaleindustries.com/wp-content/uploads/2024/08/Blasting-Blog-Sept-2019-2.png

900

1600

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2020-03-18 19:02:192026-03-05 09:12:47How To Maintain An Efficient Blast Media Work Mix https://midvaleindustries.com/wp-content/uploads/2024/08/Particle-Size-Matters-1-2.jpg

800

800

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2020-03-18 03:50:482026-03-05 09:12:48Why Particle Size Matters When Blasting

https://midvaleindustries.com/wp-content/uploads/2024/08/Particle-Size-Matters-1-2.jpg

800

800

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2020-03-18 03:50:482026-03-05 09:12:48Why Particle Size Matters When Blasting https://midvaleindustries.com/wp-content/uploads/2024/08/Adobe-Spark1-2.jpg

838

1600

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2020-03-18 03:21:172026-03-05 09:12:49Choosing The Correct Blast Hose Size

https://midvaleindustries.com/wp-content/uploads/2024/08/Adobe-Spark1-2.jpg

838

1600

JBeasley

/wp-content/uploads/2024/06/Midvale-Logo-Web-Black.png

JBeasley2020-03-18 03:21:172026-03-05 09:12:49Choosing The Correct Blast Hose Size