6 Reasons You Should Use Starch Abrasive On Aerostructures

1.) Preserves Aircraft Integrity

Traditional aerospace coating removal processes can cause damage to the structure and tooling. Starch abrasives safely remove coatings from sensitive metallic and composite substrates with minimal effects on the mechanical properties of the airframe or component. These abrasives are less damaging and more forgiving when compared to traditional plastic media blasting (pmb) abrasives. The use of starch abrasives helps ensure that expensive assets can stay in the air longer.

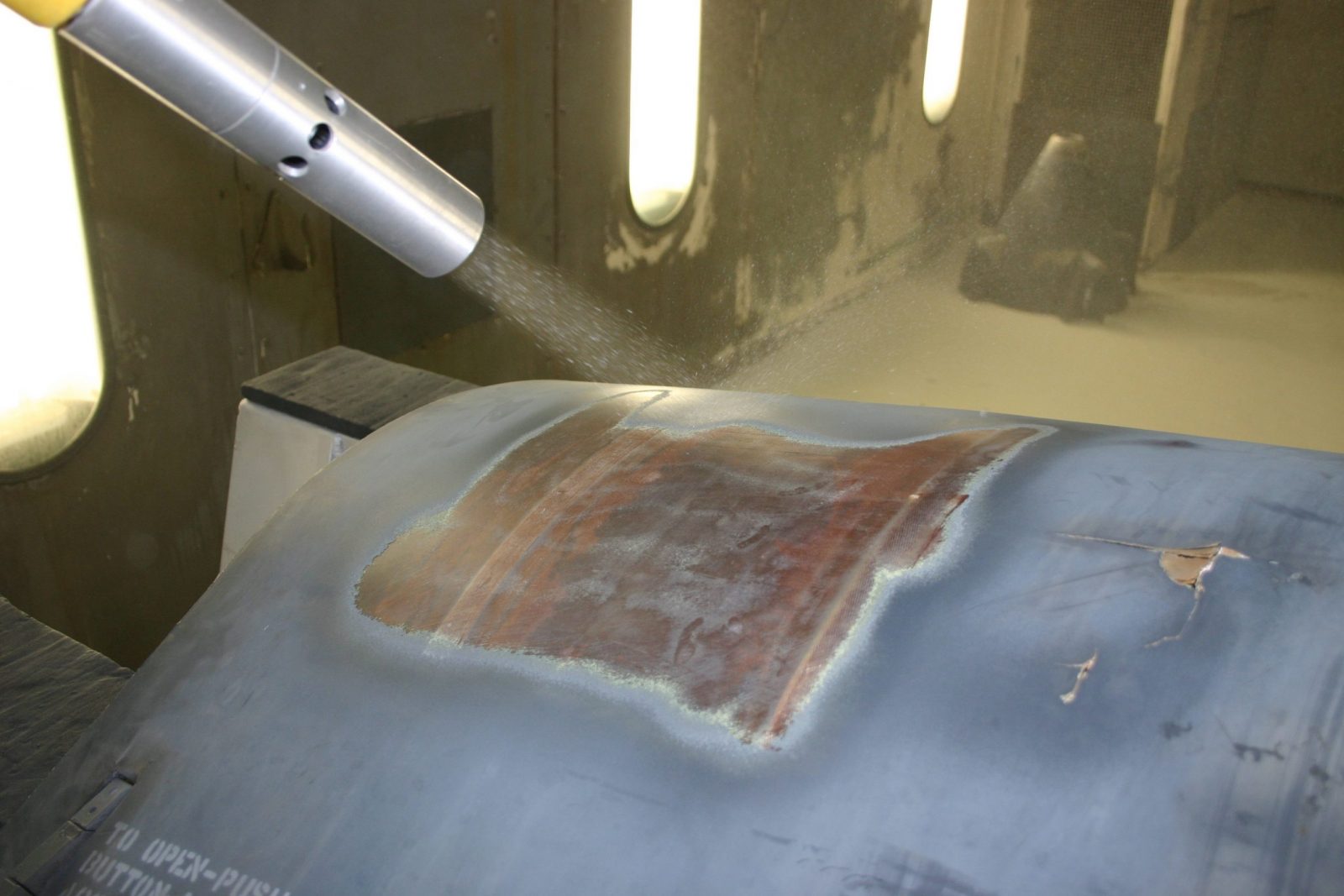

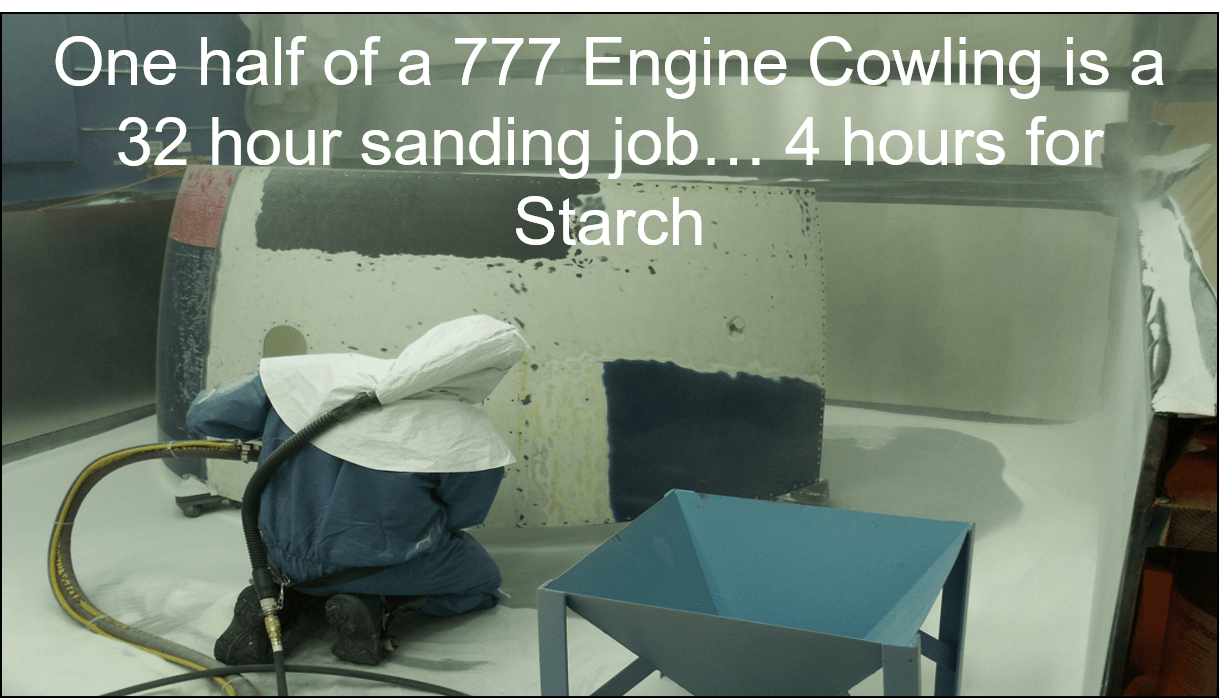

2.) Simple and Fast

The Starch Blasting Process is a repeatable process that gives consistent results. Starch abrasives remove coatings 8 to 10 times faster than hand sanding. Bio-based starch abrasives have a self-sharpening crystalline structure that ensures consistent cutting capability throughout the product’s life. Starch abrasive can be used in multiple blast processes including blast pots, blast cabinets, blast rooms and blast hangars.

3.) Safe To Use on Composite Material

The gentle effect of starch media on composite substrates allows selective stripping of top coats while leaving the primer coat intact, ensuring no damage to the underlying surface. The starch abrasives are very effective on advanced composite materials such as Kevlar, Fiberglass, Carbon Fiber and new Hybrid Composites, while preserving the aircraft’s original structural integrity. They are also ideal for a high volume of molds and tools cleaned on a daily basis.

4.) Protects Workers

Converting to an abrasive blasting process removes the risk of ergonomic injuries related to machine hand sanding such as Hand Arm Vibration Syndrome, Muscular Skeletal Disorders and Repetitive Motion Injury. It also protects workers from harmful and volatile organic compounds typically present during chemical stripping and with certain plastic media types.

5.) Environmentally Friendly Product & Recycling Program

Starch Abrasives are a natural bio-based abrasive. They are made from renewable and sustainable resources. Midvale Environmental Technologies has an approved recycling and handling program that eliminates hazardous waste and reduces overall disposal costs. This recycling program is approved in many states including California and Florida.

6.) Nationally Recognized

Midvale Environmental Technologies was recognized along with the U.S. Coast Guard’s Aircraft and Supply Center when they were awarded the Closing the Circle Award for eliminating their blasting facility’s hazardous waste while reducing disposal costs. Midvale Environmental Technologies was recognized along with the Navy and their Green Procurement initiative for their starch media usage.

View Other Applications for Starch Abrasives:

Metal Bond Deflash

Composite Tool Cleaning

Composite Bond Prep

Test Starch Abrasives

Get in touch with our team today and schedule a trial run of starch abrasives on your parts.