Firearms & Ammunition Finishing

Firearm and ammunition finishing solutions designed to produce the highest quality firearm components and ammunition casings. Each finishing process is designed specifically to each application, whether it is to profile or etch parts, or to provide a smooth, cosmetic finish. Midvale Industries specializes in the process development of finishing solutions that include equipment, automation or robotics, and the media required to produce precise and quality parts.

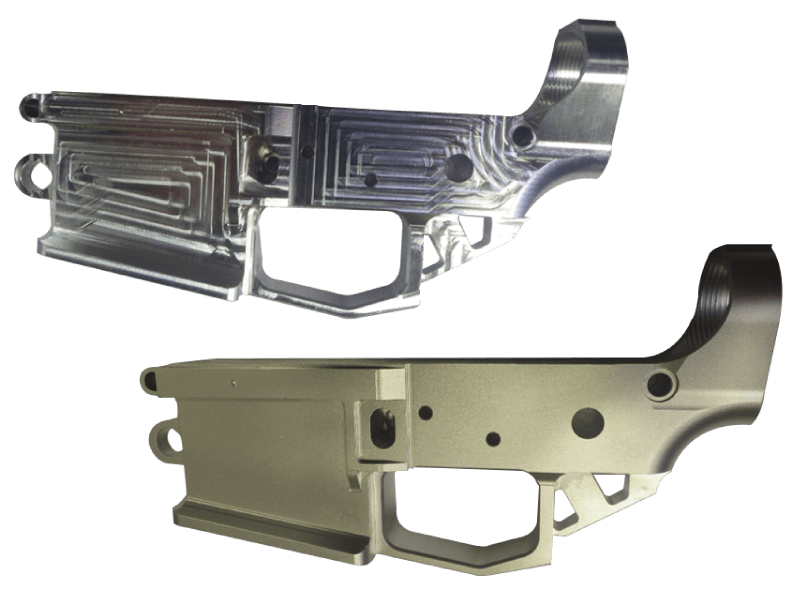

Firearms Finishing

Firearm finishing requires a repeatable and high quality process to ensure you have a consistent product reaching the market. We offer multiple lines of equipment and media to ensure you have the best firearm components.

Ammunition Finishing

Ammunition mass finishing provides a consistent, clean finish to casings of any size. Batch processing allows for fast and repeatable results. We provide multiple solutions for mass finishing both new and used ammunition casings.

Firearm Finishing

Midvale provides engineered finishing solutions that deliver repeatable, quality results for firearm components. Whether you need to clean, polish, profile or etch parts, or to provide a smooth, cosmetic finish, we can develop a solution for your application. Finishing processes include wet blasting, air blasting, automated polishing, and blasting abrasives. Each system is designed to fit the needs of your application to provide precision, speed, automation and quality.

Wet Blasting

- Ideal for smooth, cosmetic finishes

- Dust free blasting environment

- Little to no media embeddment

- Less production floor space required

- Automation and robotics available

Air Blasting

- Ideal for cleaning, deburring, profiling

- Single part or batch processing

- Automation and robotics available

Polishing

- Ideal for smooth, bright finishes

- Automation and robotics available

Blast Media

Midvale carries a full line of blast media including aluminum oxide, ceramic, and glass beads that provide smooth and bright finishes.

Ammunition Finishing

Midvale provides engineered vibratory finishing and parts cleaning solutions that deliver repeatable, quality results for both new and used ammunition casings. Whether you need to clean or polish, we can develop a solution for your application. Each system is designed to fit the needs of your application to provide precision, speed, automation and quality.

Batch Vibratory Finishing

Quickly process new or used ammunition in batches. These systems can combine burnishing and drying all in the same unit.

Continuous Vibratory Finishing

Quickly process large quantities of new or used ammunition casings with a continuous feed. This limits down time in your production.

Batch Centrifugal Finishing

Centrifuglar finishing produces finishing results at a rate of 10 to 15 times faster than traditional vibratory equipment.

Rotary Drum Parts Washers

Rotary drum parts washers provide cleaning, rinsing, and drying for your ammunition. Ideal for hollow point casings.

Vibratory Media & Compound

Midvale Industries offers a broad line of vibratory media and compounds for a variety of mass finishing processes. Vibratory Media and Compound are both critical to achieving a consistent and precise finish. Vibratory media options include steel, ceramic, plastic and corn cob drying media.

Repeatable Processes

Consistent Quality

Superior Finish

Get In Touch

Contact us to talk to our trained consultants. We will work with you to find the best solution for your firearm & ammunition application. Ask us about setting up a trial to help develop a process with proven results.

Phone

800-341-0043

info@midvaleind.com