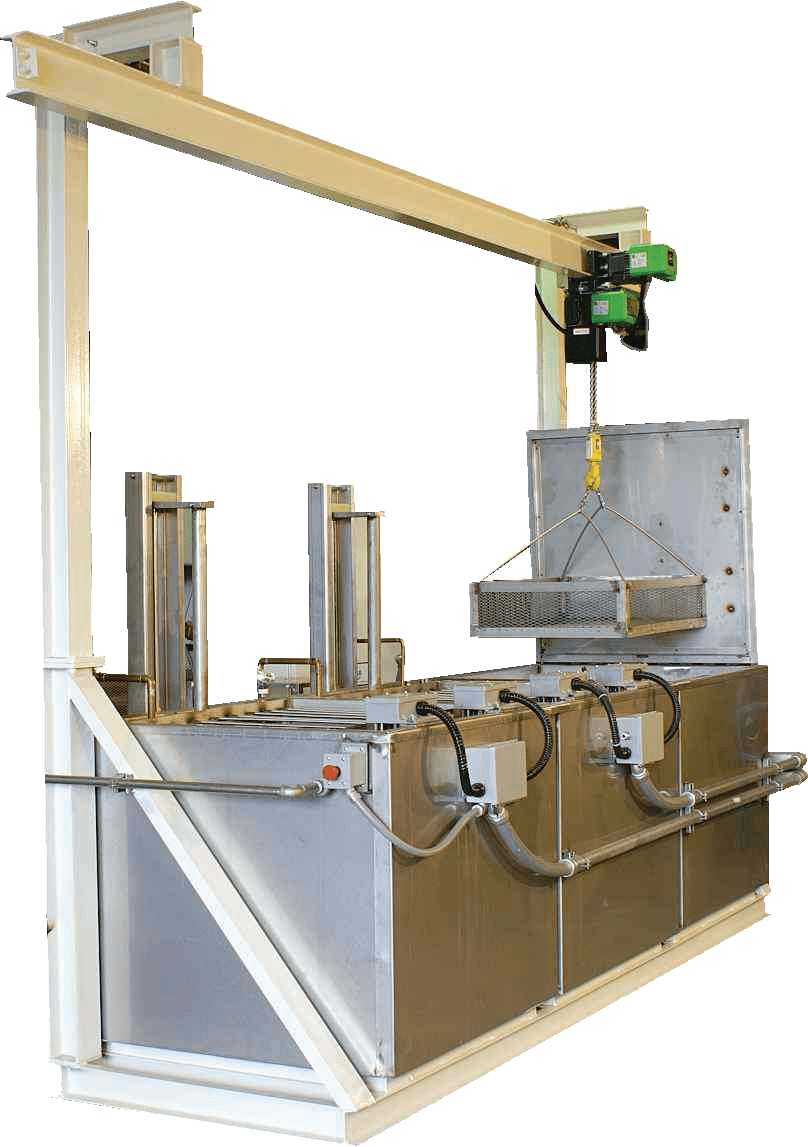

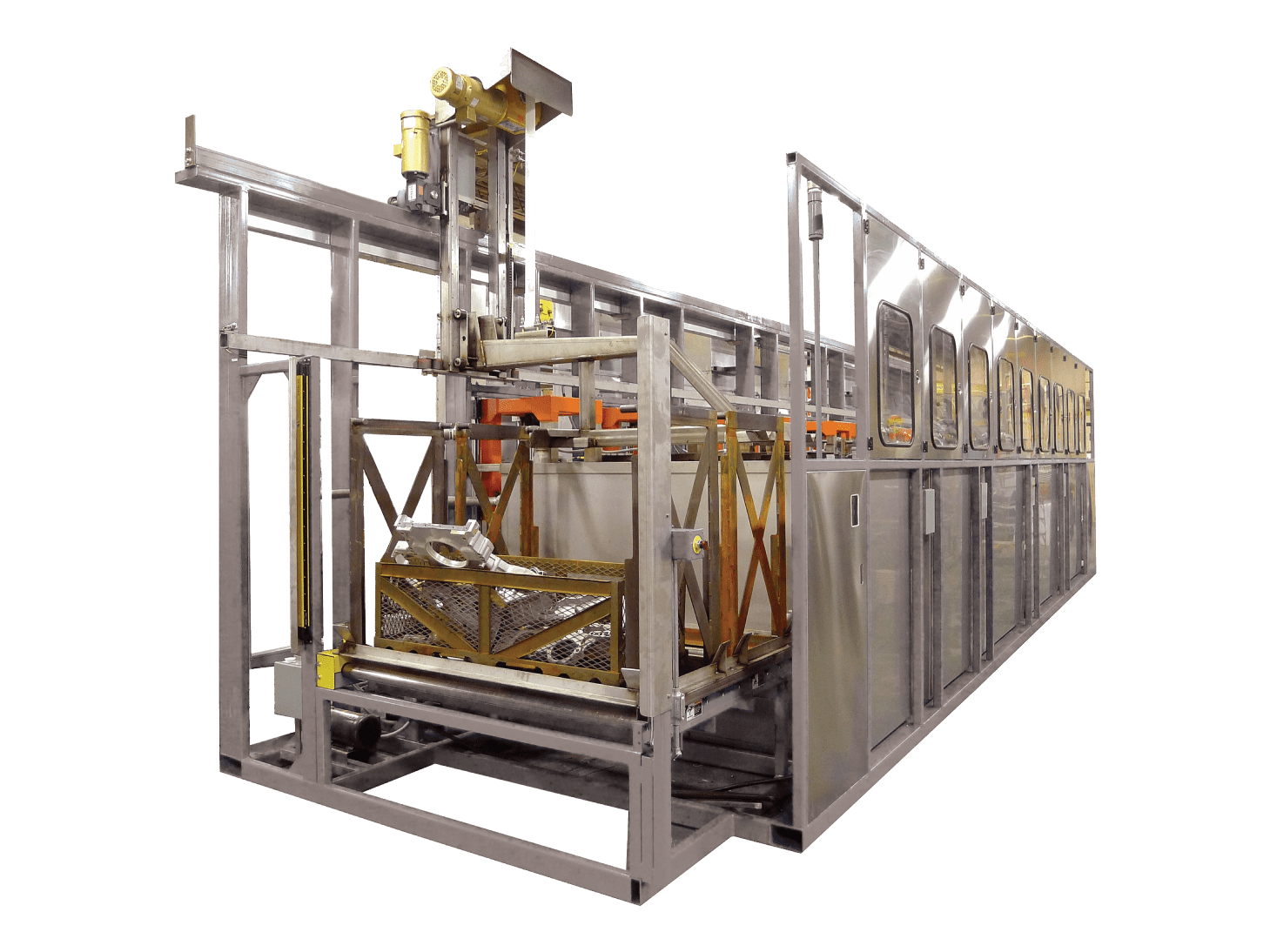

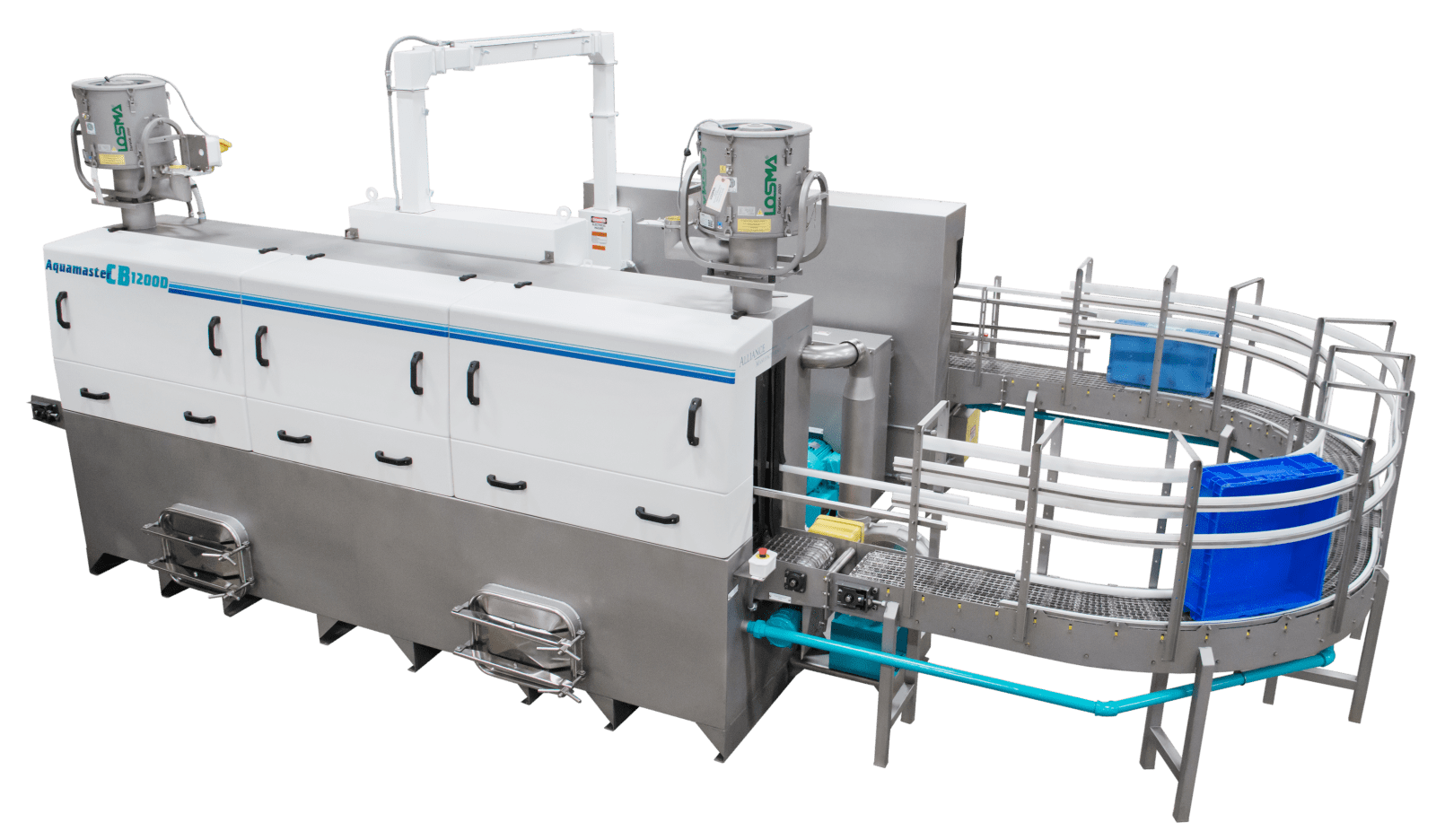

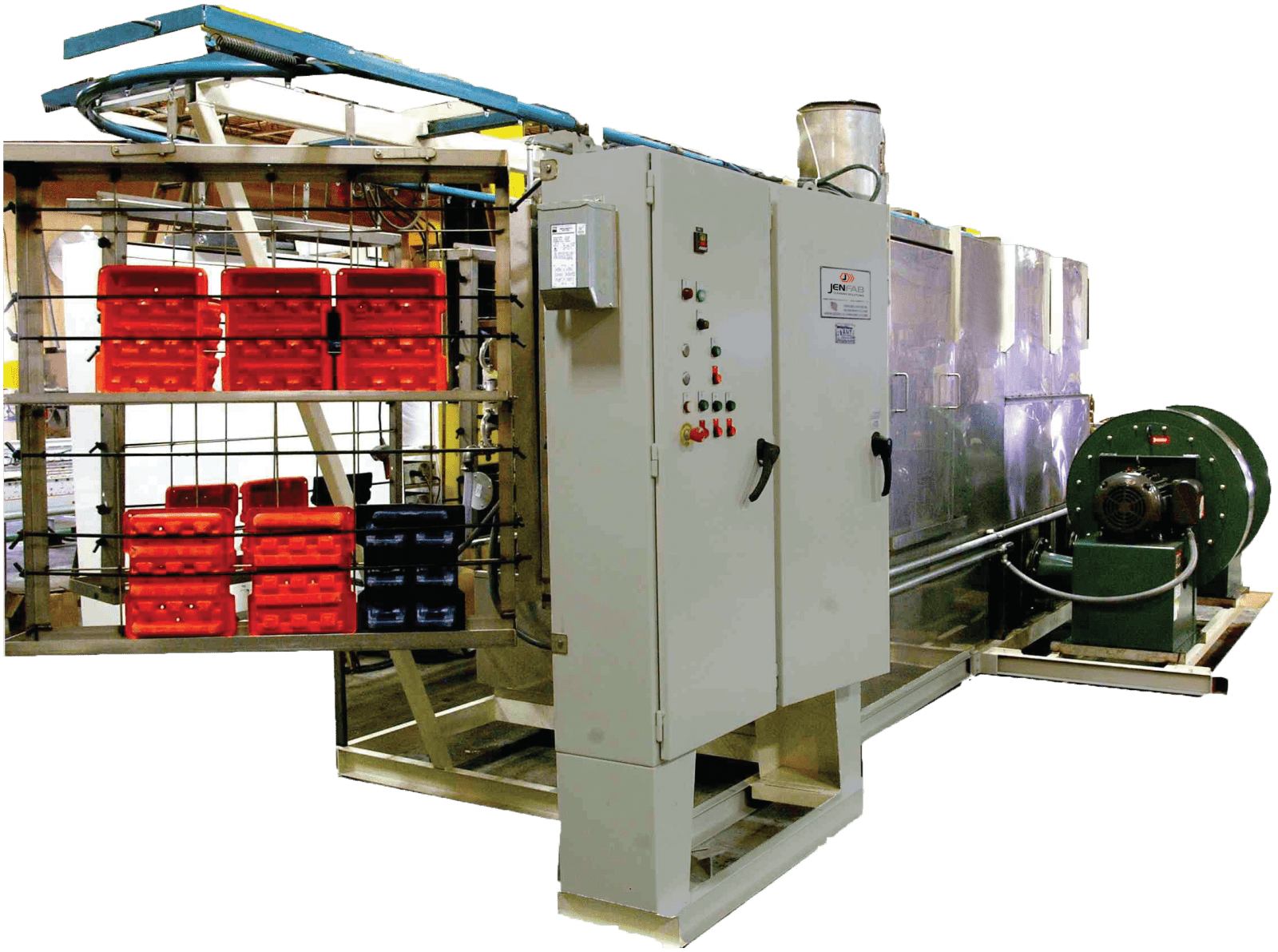

Vacuum Vapor Degreaser

Vapor Degreasing

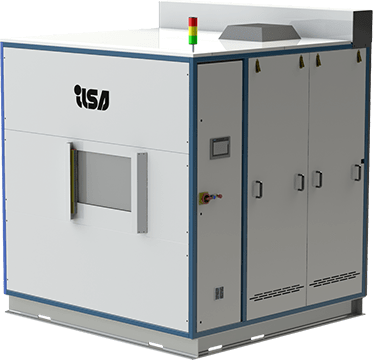

Vacuum vapor degreaser cleaning systems provide a precise finish to metal parts. These systems are ideal when there are strict cleanliness specifications. Vapor degreasing systems efficiently clean and remove coolants, chips, and other soils from precision machined parts. Highly effective on precision machined and turned parts.

Environmentally Friendly Cleaning Application

Vacuum degreasers utilize self-contained cleaning process inside an enclosed chamber utilizing safer solvents (or modified alcohol), greatly reducing human exposure to chemicals. The vacuum degreaser both cleans and dries the parts within the chamber, leaving behind no solvent residue when you remove the parts.

Typical Applications:

- Aerospace

- Medical

- Precision Machined Parts

- Hydraulic Components

- Micromechanical Parts

- Turned Parts

- Screw Machined Parts

- And More!

Key Features:

- Contained Cleaning Chamber

- Cleans AND Dries Parts Inside Chamber

- Rust Inihibiting Options

- Minimal Solvent Usage

- Low Levels of Waste Removal Required

- Multiple Sizes Available

- Small Footprint

- Capable of Cleaning Metal & Plastics

Vapor Degreasing Solvent

Our vacuum degreaser machines utilize the following safe materials for cleaning precision parts:

- Modified alcohols

- Aliphatic hydrocarbons

Vacuum degreasing systems are designed to replace these common vapor degreasing solvents:

- Trichloroethylene (TCE)

- Perchloroethylene (Perc)

- Methylene Chloride

- Normal Propyl Bromide (nPB)

- Hydrofluoro solvents (HFC/HFE)

What is Vapor Degreasing?

Vapor degreasing utilizes solvents to remove contaminants from metal or plastic components. Traditional open-top degreasers allow for the chemicals to enter the air, bringing risk to the workers. Our vacuum vapor degreasing units are a closed-cleaning system. This removes EHS concerns. The vacuum keeps everything contained and processed for waste removal.

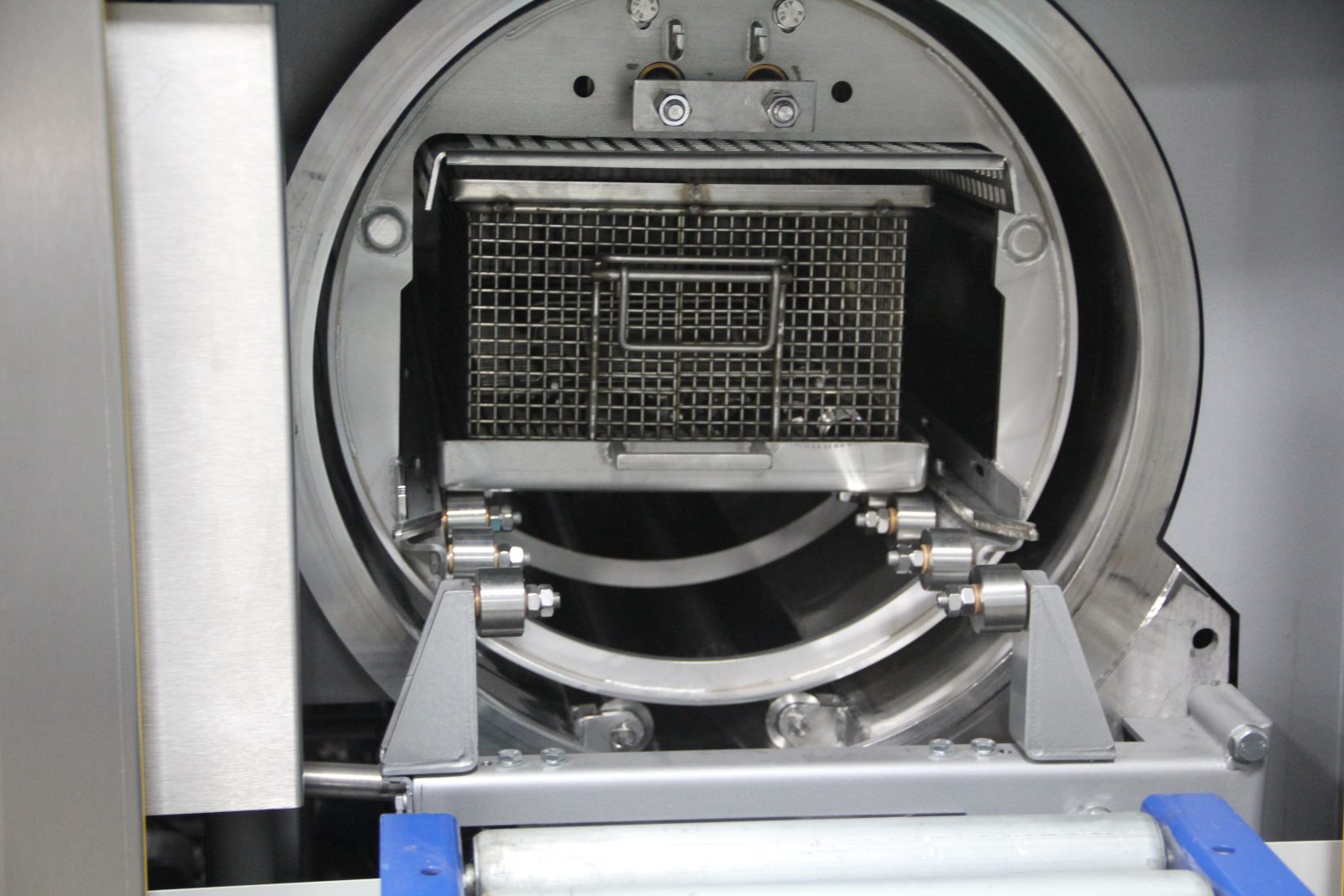

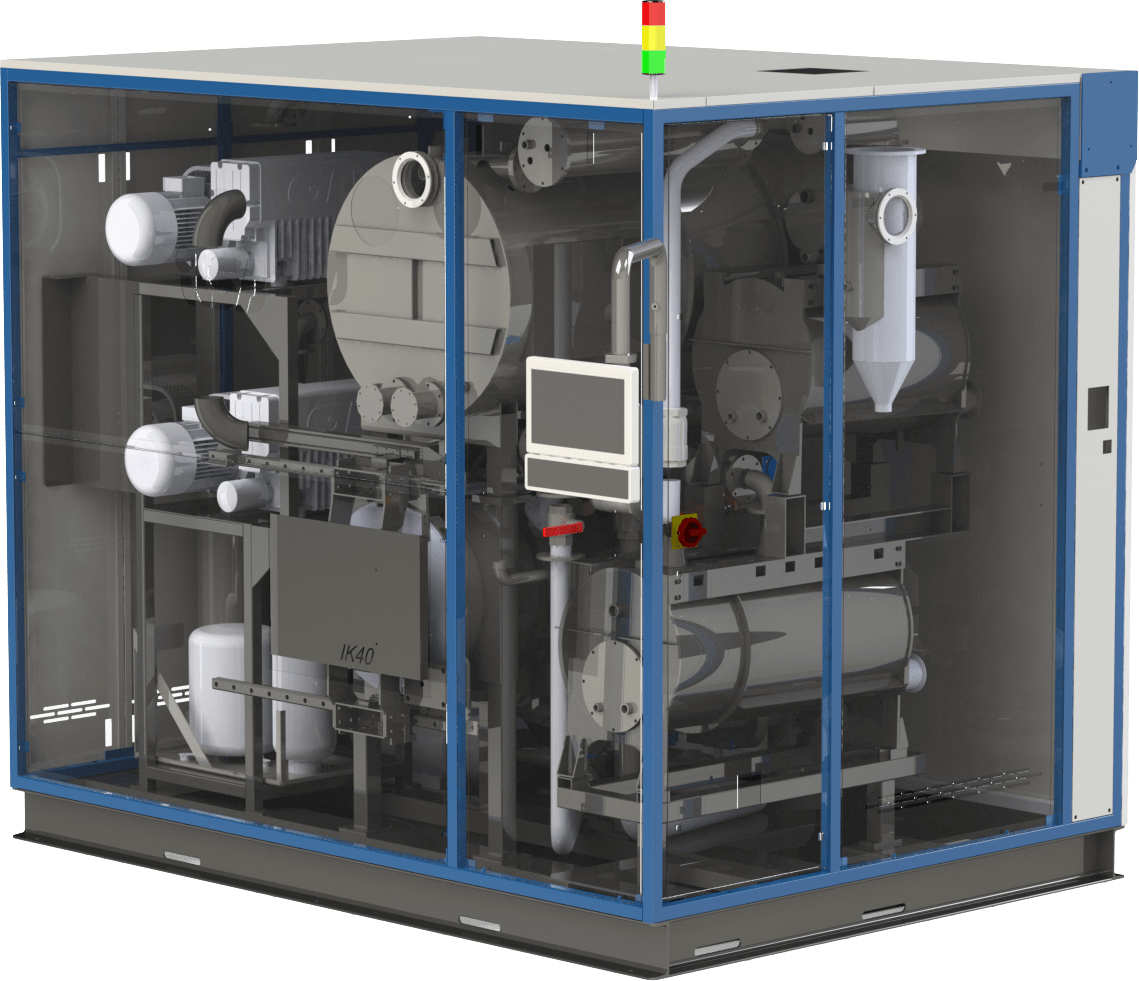

How Does Vacuum Vapor Degreasing Work?

The degreaser vacuums out all of the air and seals off the cleaning chamber, eliminating emissions leaking out into the workspace.

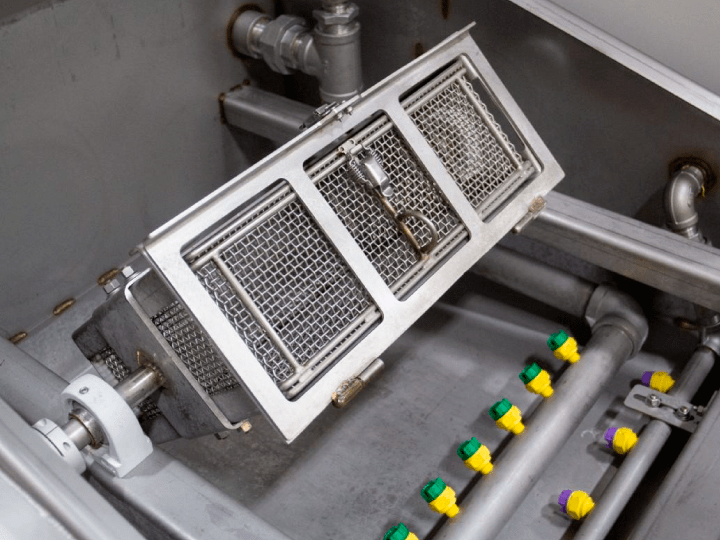

Due to the vacuumed environment, the solvents boiling point is reduced. The lower temperature helps reduce energy use. The unit as ultrasonics included as the parts are immersed in the solvent solution. There is also high pressure spray inside the chamber.

Once all cleaning stages are finished, the vacuum pulls all of the liquid from the chamber, leaving the parts warm and dry when the basket exits the cleaning chamber.

Have A Question?

Contact us today to talk to a LIVE representative. We can answer your questions, set up a site visit, or work out details for a trial of our products! Our team of technically trained sales representatives are backed by years of industrial knowledge and practice to help develop the best processes for your applications.

Recent Comments