Alloy Recovery

Improve Alloy Recovery

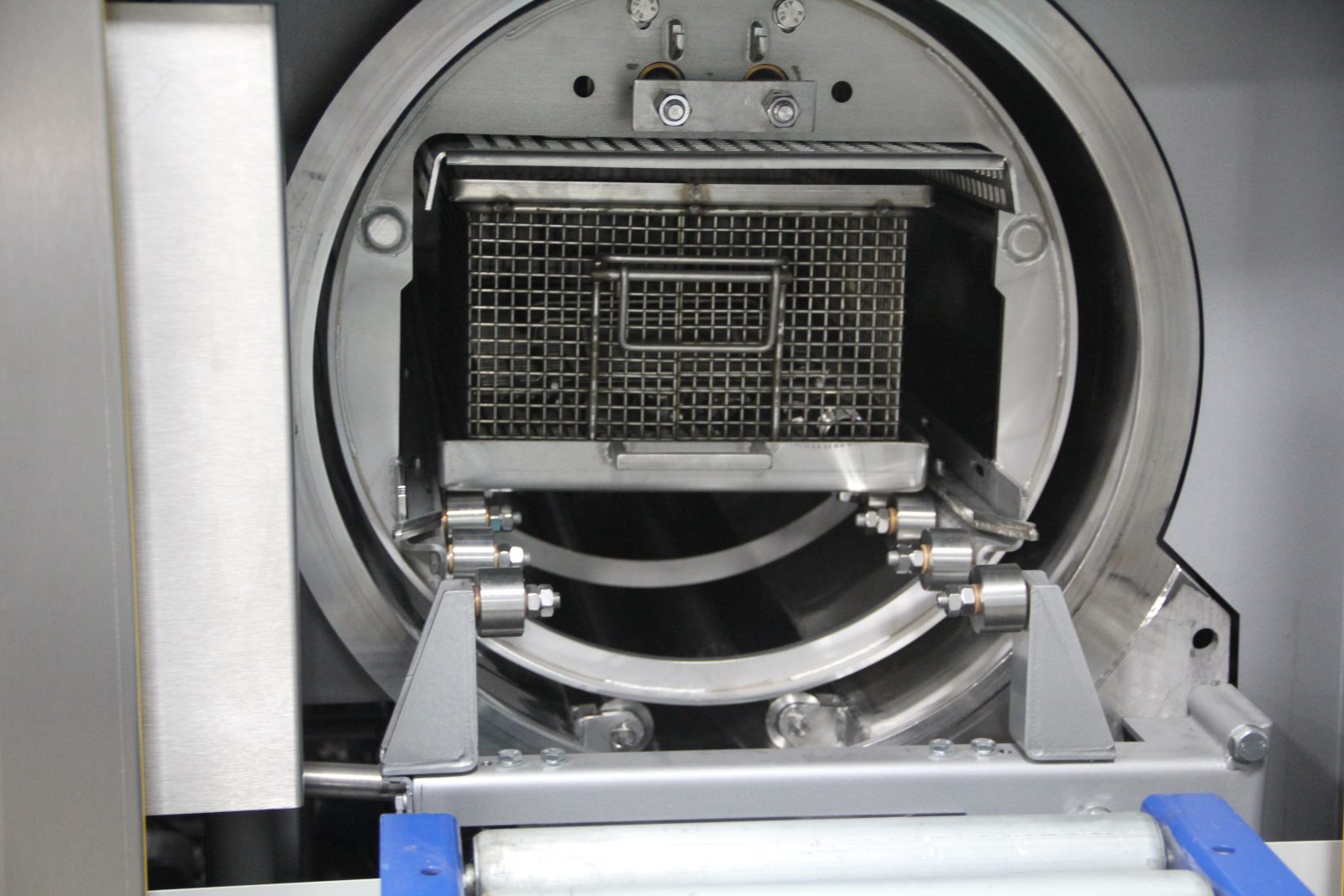

Improve the alloy recovery in your metalcasting applications with the use of Mag Guard. Mag Guard is a steel alloy cover designed for high density and low permeability to delay reaction of the alloy, improving manganese recovery. The unique shape and composition of Mag Guard allows for full and superior coverage of your alloys, providing quality protection. Improved recovery and protection reduces cost and time spent in your melt department.

Key Highlights:

- Clean

- Oil Free

- Rust Free

- Reduce Temperature Loss

- Easy Handling

Size Specifications:

- 4 mesh x 14 mesh

Midvale Industries is a proud member of the AFS (American Foundry Society), FEF (Foundry Educational Foundation), Ductile Iron Society, NADCA (North American Die Casting Association) and the NFFS (Non-Ferrous Founders' Society).

Have A Question?

Contact us today to talk to a LIVE representative. We can answer your questions, set up a site visit, or work out details for a trial of our products! Our team of technically trained sales representatives are backed by years of industrial knowledge and practice to help develop the best process for your applications.

Recent Comments