Roto-Max

Roto-Max

High-Energy Mass Finishing Process

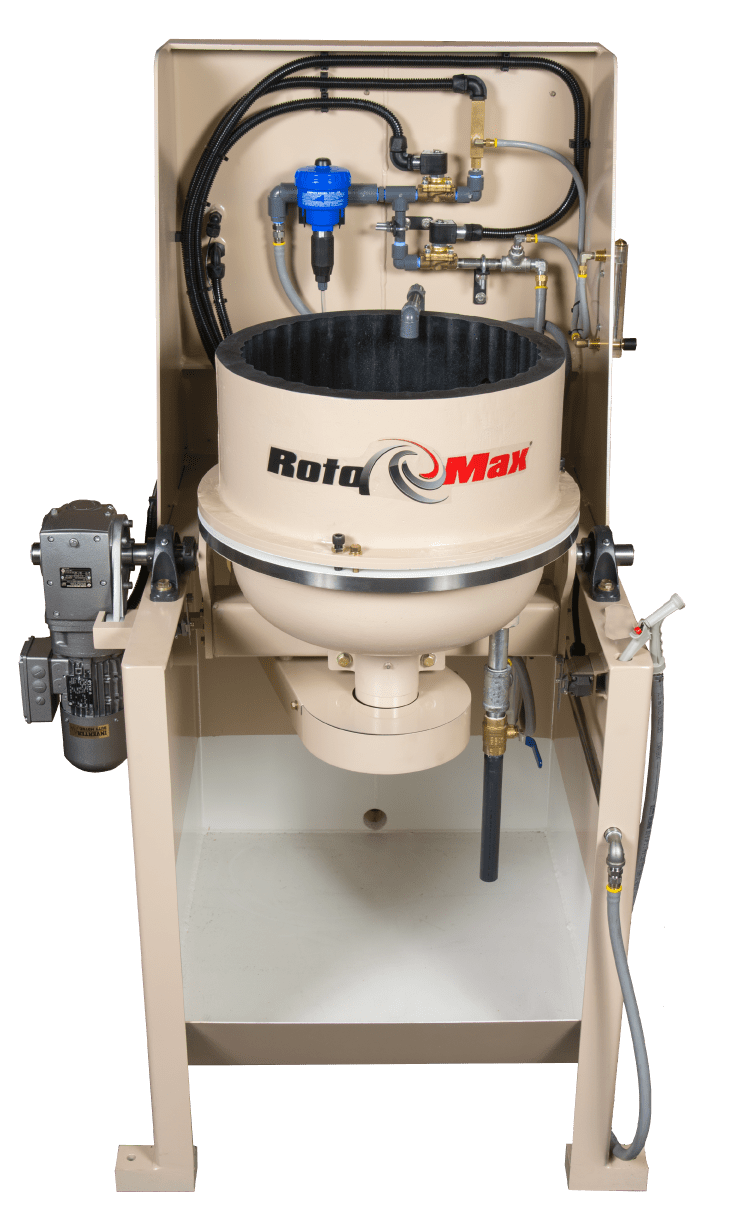

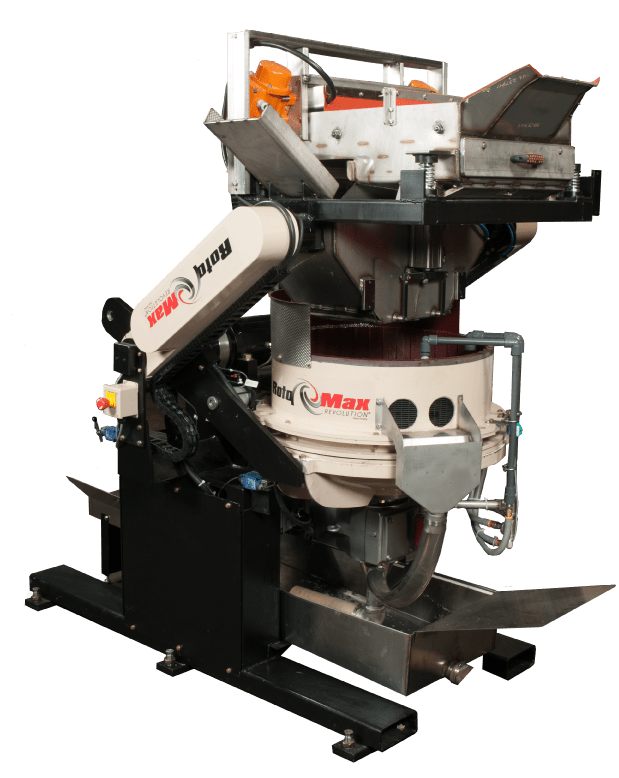

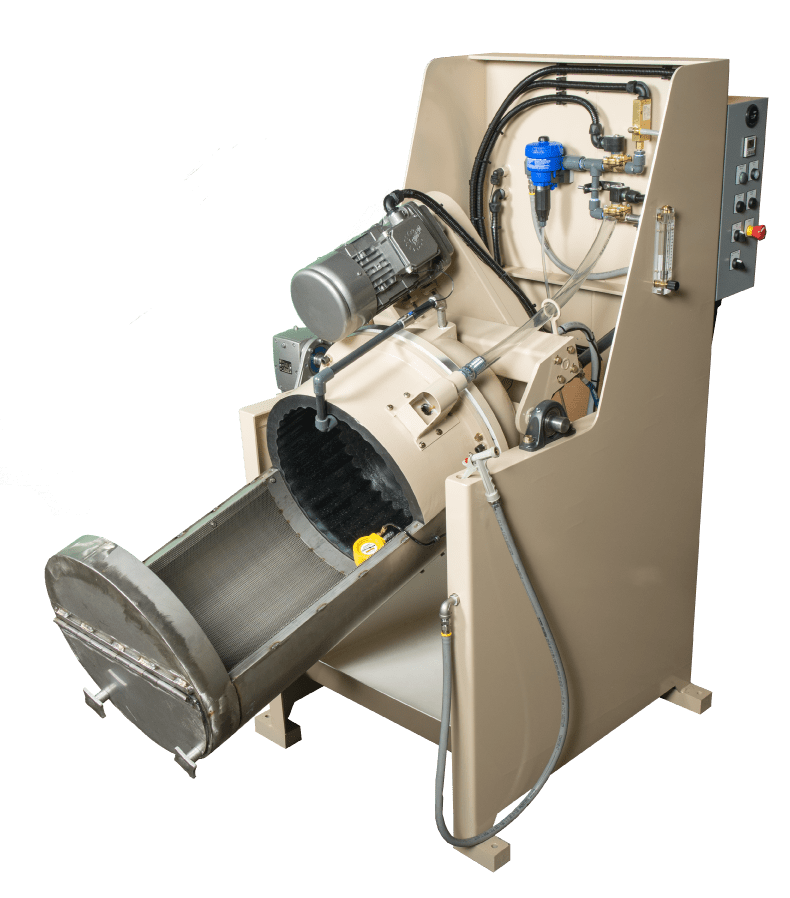

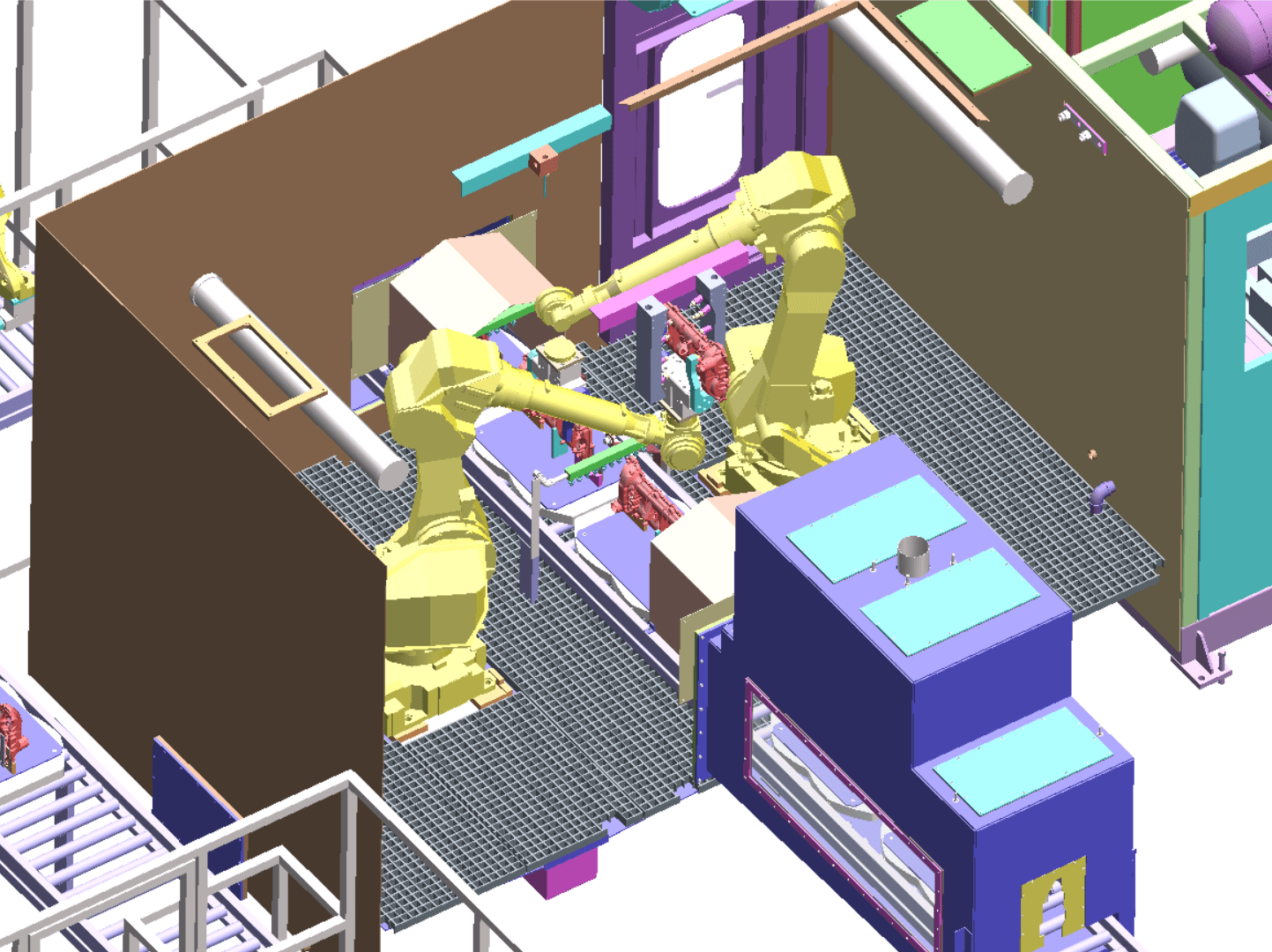

The Roto-Max® and Roto-Max® Revolution lines are a series of high energy centrifugal energy machines. The machine functions with a rotating disc or spinner in the bottom of the finishing chamber, and a stationary wall that the rotating disc meets with a precision gap. This system utilizes compound and water to help move the debris up and out of the finishing chamber.

The part and media mix is pushed outward on the rotating disc to the stationary sidewall. As the media is pushed, pressure builds and pushes the media and parts upward on the sidewall until the media falls back to the center of the rotating disc in a cyclonic action. This smooth and continuous motion produces an energy level up to 15 times greater than normal vibratory finishing systems.

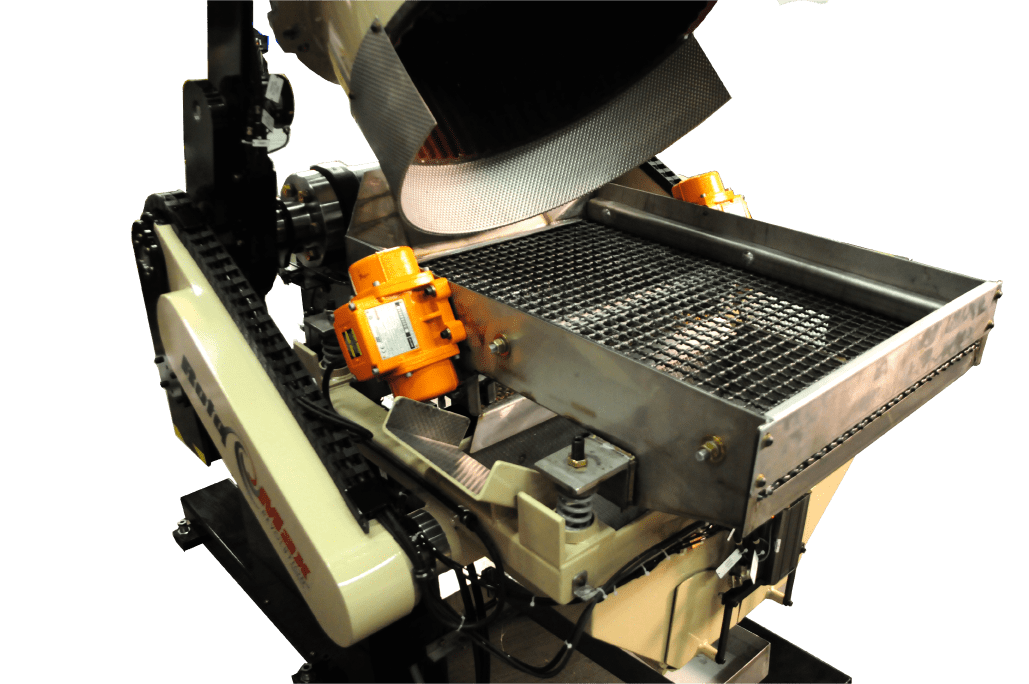

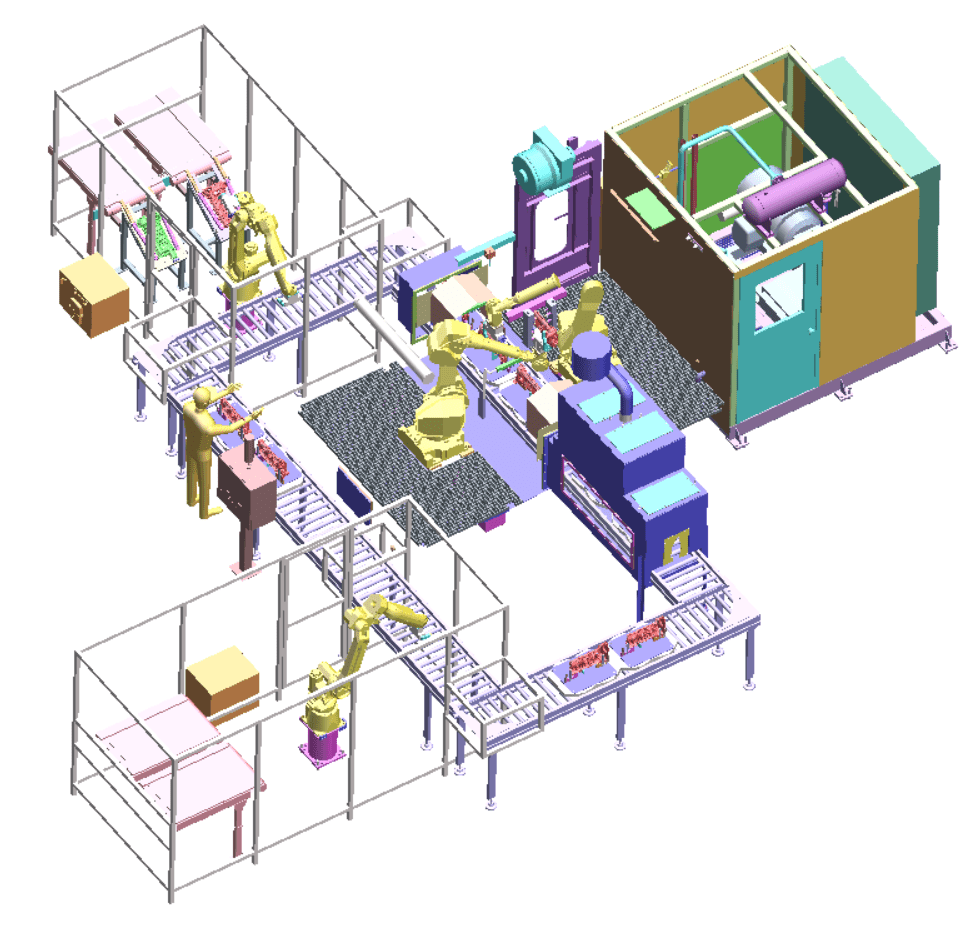

The Roto-Max® Revolution has a built in media separator. This allows for shorter load times to get the machine running on your next cleaning job. The Roto-Max® Revolution is compact and can be easily expanded to accept added features for material handling, or secondary processing steps.

Have A Question?

Contact us today to talk to a LIVE representative. We can answer your questions, set up a site visit, or work out details for a trial of our products! Our team of technically trained sales representatives are backed by years of industrial knowledge and practice to help develop the best processes for your applications.

Recent Comments