Riser Sleeves

Midvale provides exothermic riser sleeves, insulating riser sleeves, and mini-riser sleeves to improve your casting feeding process.

Riser Sleeves

Riser sleeves provide insulation to reduce heat loss from the riser (insulated sleeves), to generate heat to maintain temperature from lost heat (exothermic sleeves), or do both. Sleeves provide consistency by reducing shrinkage and improving overall casting quality. Riser sleeves also reduce labor costs by providing easier riser knock off and a smaller contact area (breaker-cores).

The sleeves we provide to our customers are inspected for consistency in their density, roundness, and wall thickness, ensuring consistency in your process. They are also engineered to be used in all molding systems and molding machines with a variety of sleeve shapes to choose from (straight, necks, downs, domes, and more).

Exothermic Riser Sleeves

Create heat and reduce metal shrinkage with exothermic riser sleeves. The top of the sleeve lights off the metal to have it flow back to the casting, reducing metal loss. Also offer hot toppings to prevent metal shrinkage.

Insulating Riser Sleeves

Reduce heat loss during metal pouring with insulating riser sleeves.

Other Sleeve Options:

We offer riser sleeves for iron, steel, and nonferrous foundries. Many styles of sleeves are available including insulating and exothermic mixes. See below for types of riser sleeve shapes.

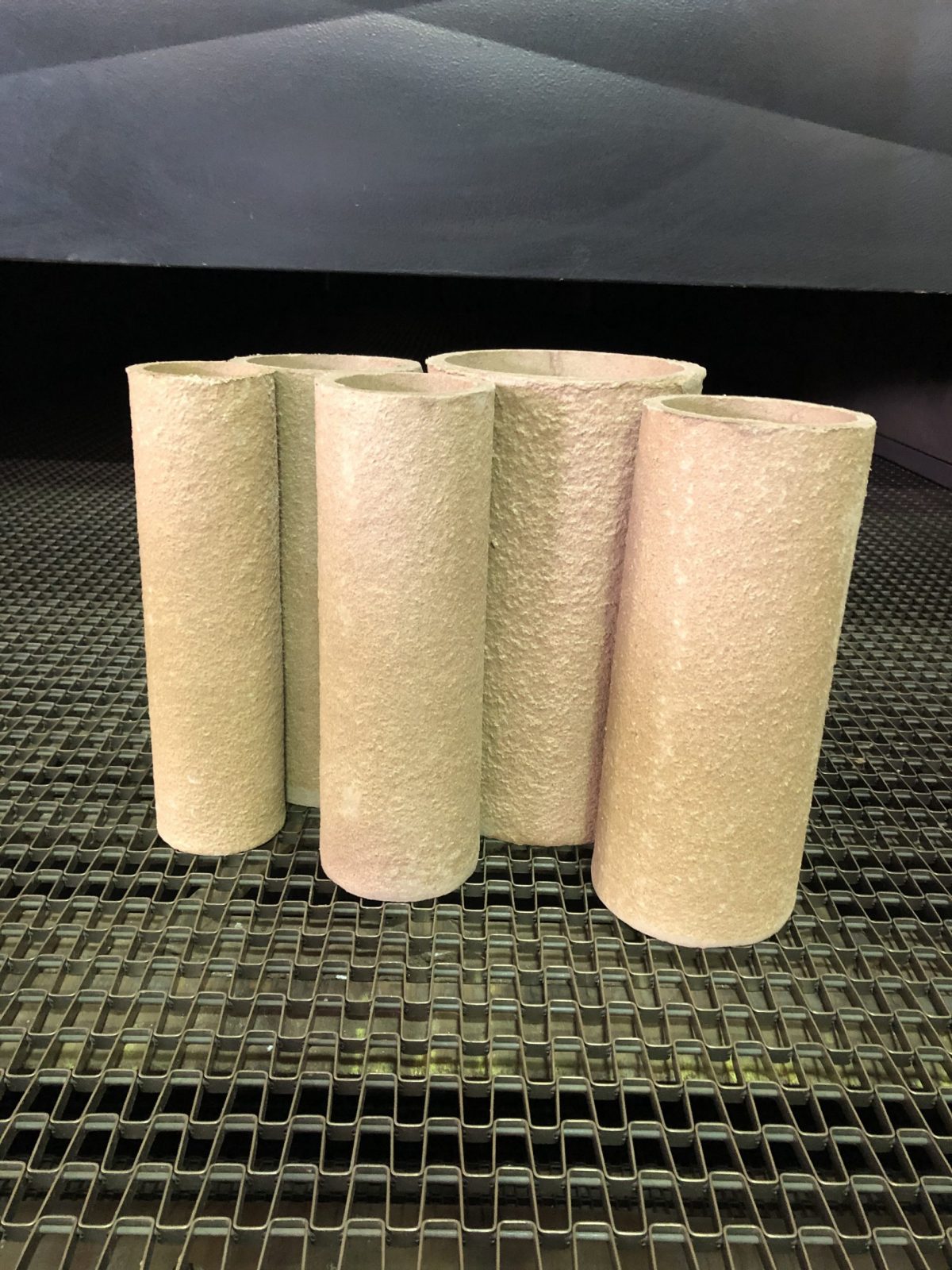

Straight Sleeves

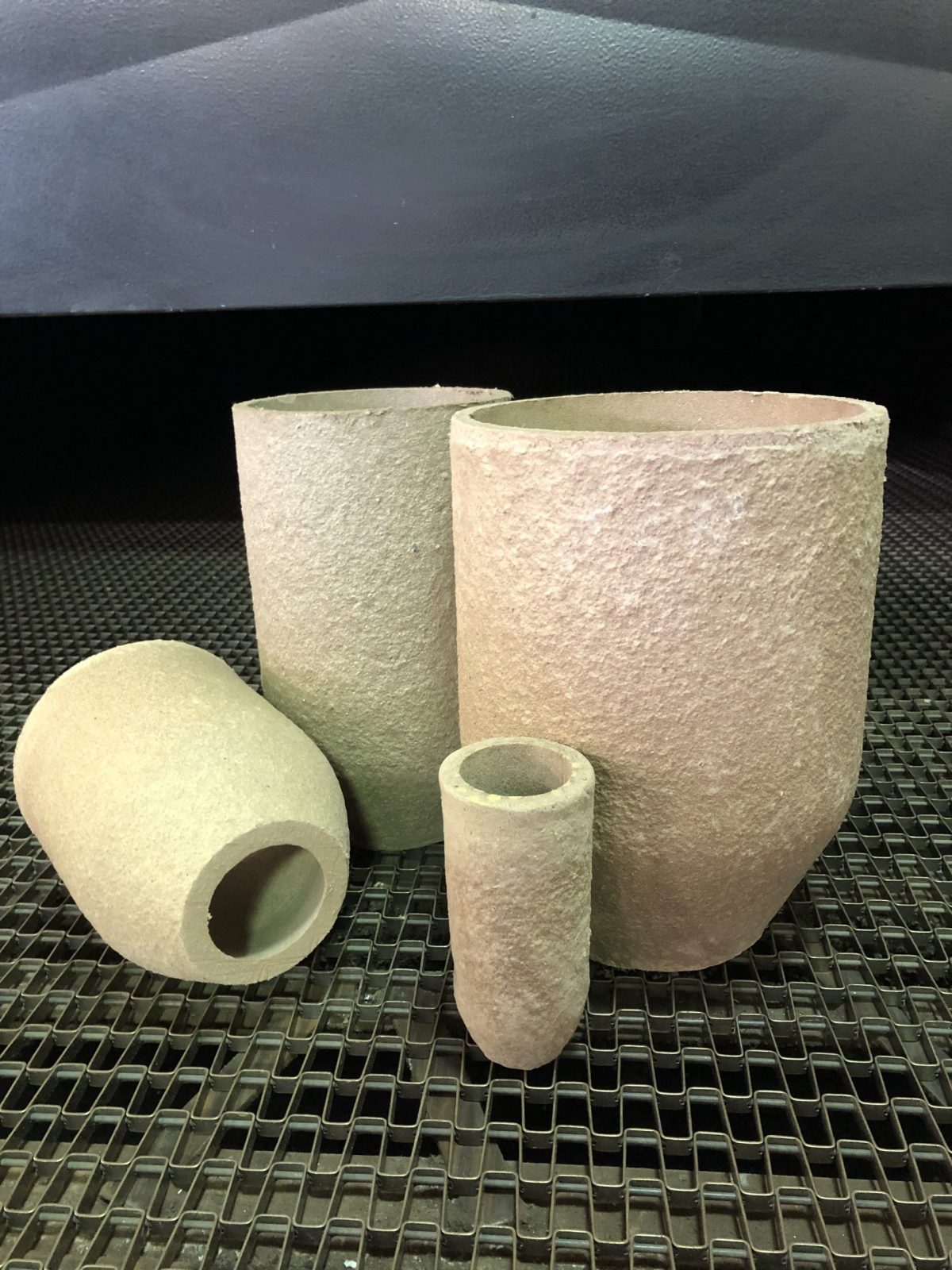

Dome Sleeves

Round Neck Down Sleeves

Direct Pour Cups

Breaker Core Inserts

Mini Riser Sleeves

The Mini Riser is a highly exothermic sand riser that utilizes the relationship between the volume of the casting divided by the surface area, which is referred to as the modulus of the casting. Calculating this modulus will allow the exothermic riser to be positioned at the thickest section of the casting. The thickest section of the casting will be the location of the highest modulus, and the last part to solidify. Because of the high exothermic content, the mini riser insulating sleeve will burn hotter for a longer time and provide a greater feeding capability then a conventional exothermic riser or other exothermic foundry supplies.

-Works hard with no contamination of sand systems

-Even, consistent, prolonged burn rate – burn temperatures exceeding 2900 degrees Fahrenheit

-Many shapes and exothermic insulating sleeve blends and types are available

-Sleeves are designed for optimum feeding conditions, with or without breaker cores, natural, low cope height molding equipment, and more

Have A Question?

Contact us today to talk to a LIVE representative. We can answer your questions, set up a site visit, or work out details for a trial of our products! Our team of technically trained sales representatives are backed by years of industrial knowledge and practice to help develop the best processes for your applications.