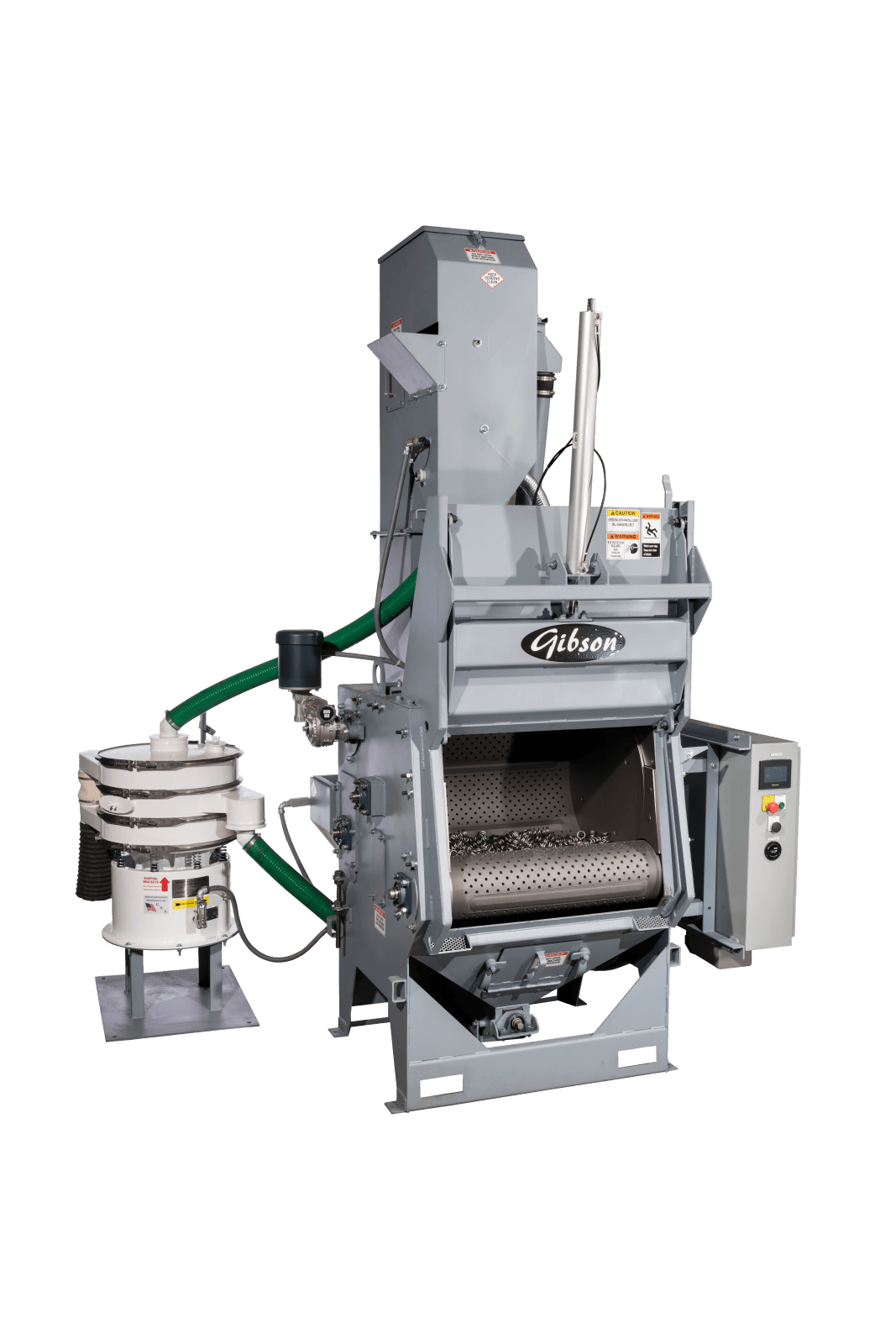

Wet Blasting Equipment

Wet Blasting Equipment

Wet blasting provides a dustless environment that greatly reduces media embedment to provide smooth, clean surface finishes. Effective at removing oily scale, etching aerospace composites, or adding a surface profile. Wet blasting is safe on composites and sensitive substrates. Wet blasting preserves the abrasive longer than traditional dry blasting. These units run on a closed-loop system providing a clean and sustainable blast environment.

Typical applications include surface cleaning, peening, etching, machine mark removal and reaching a required RA surface finish.

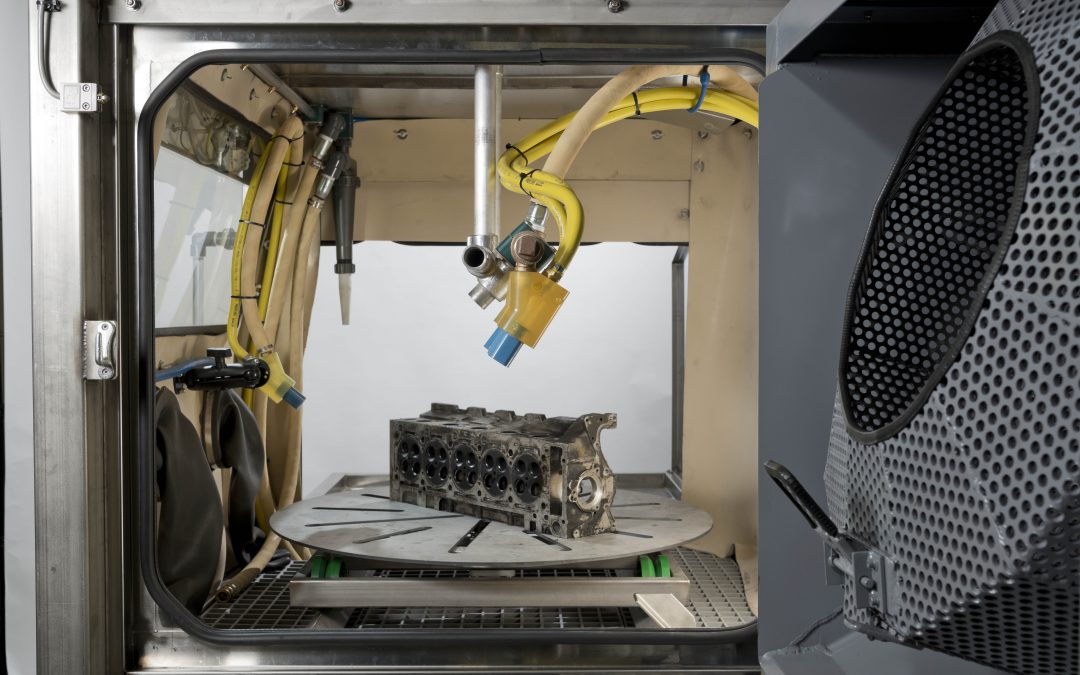

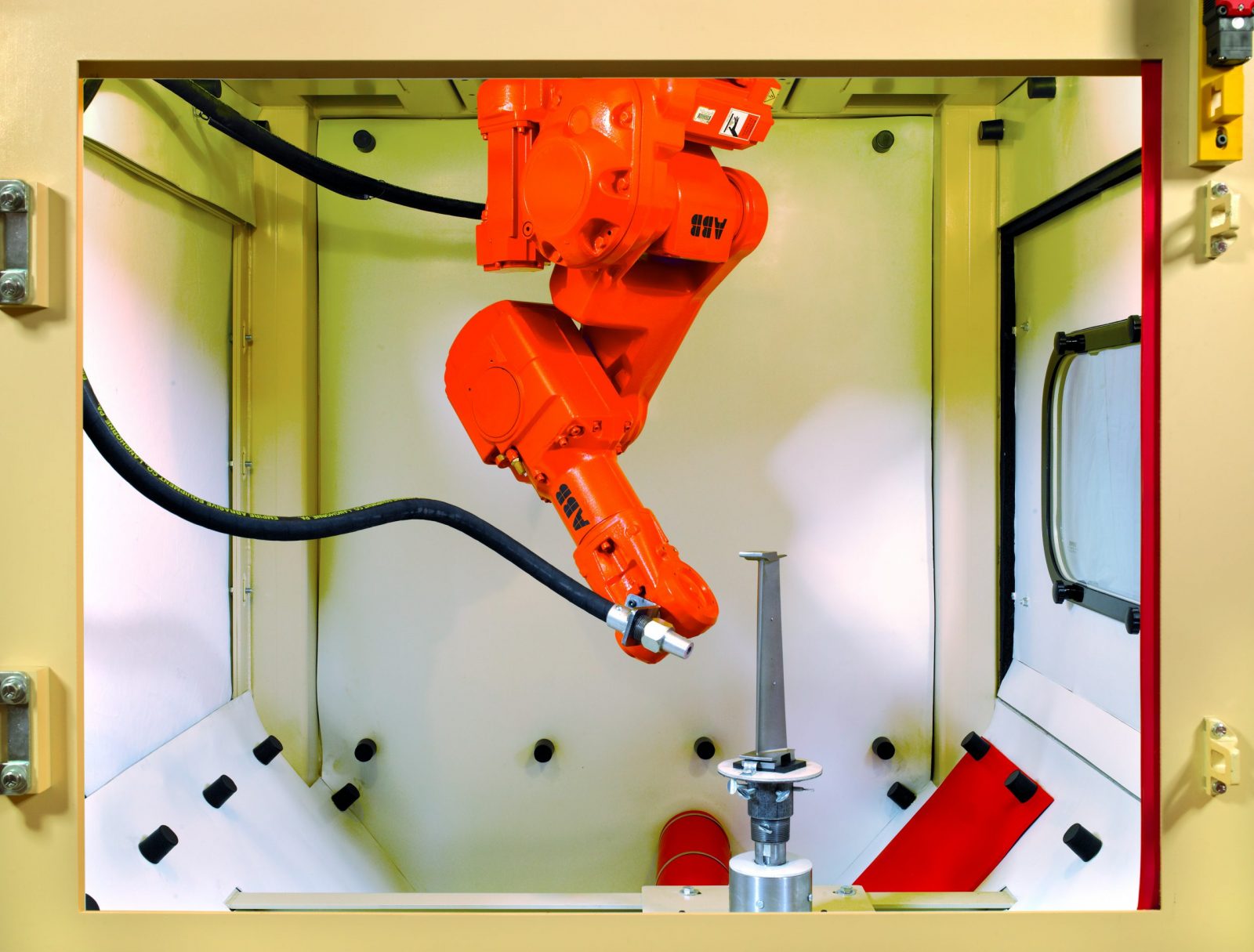

Robotic & Automated Wet Blast Equipment

Robotics systems are fully engineered for precision and highly repeatable results on sensitive applications. Each system is designed to your application.

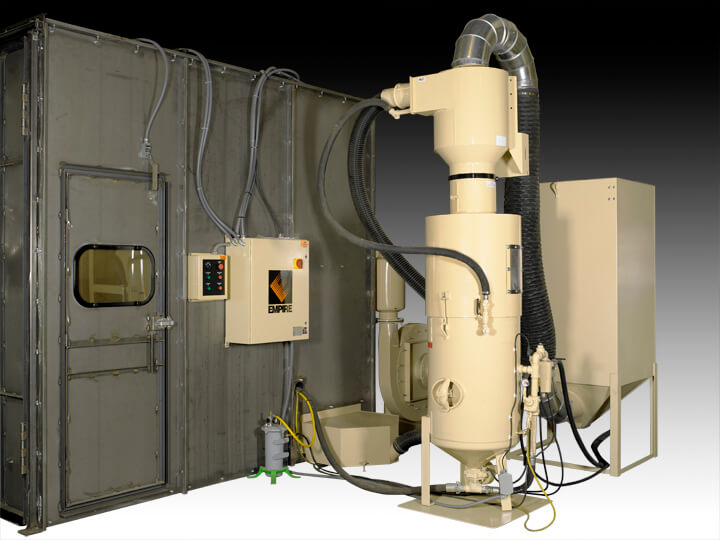

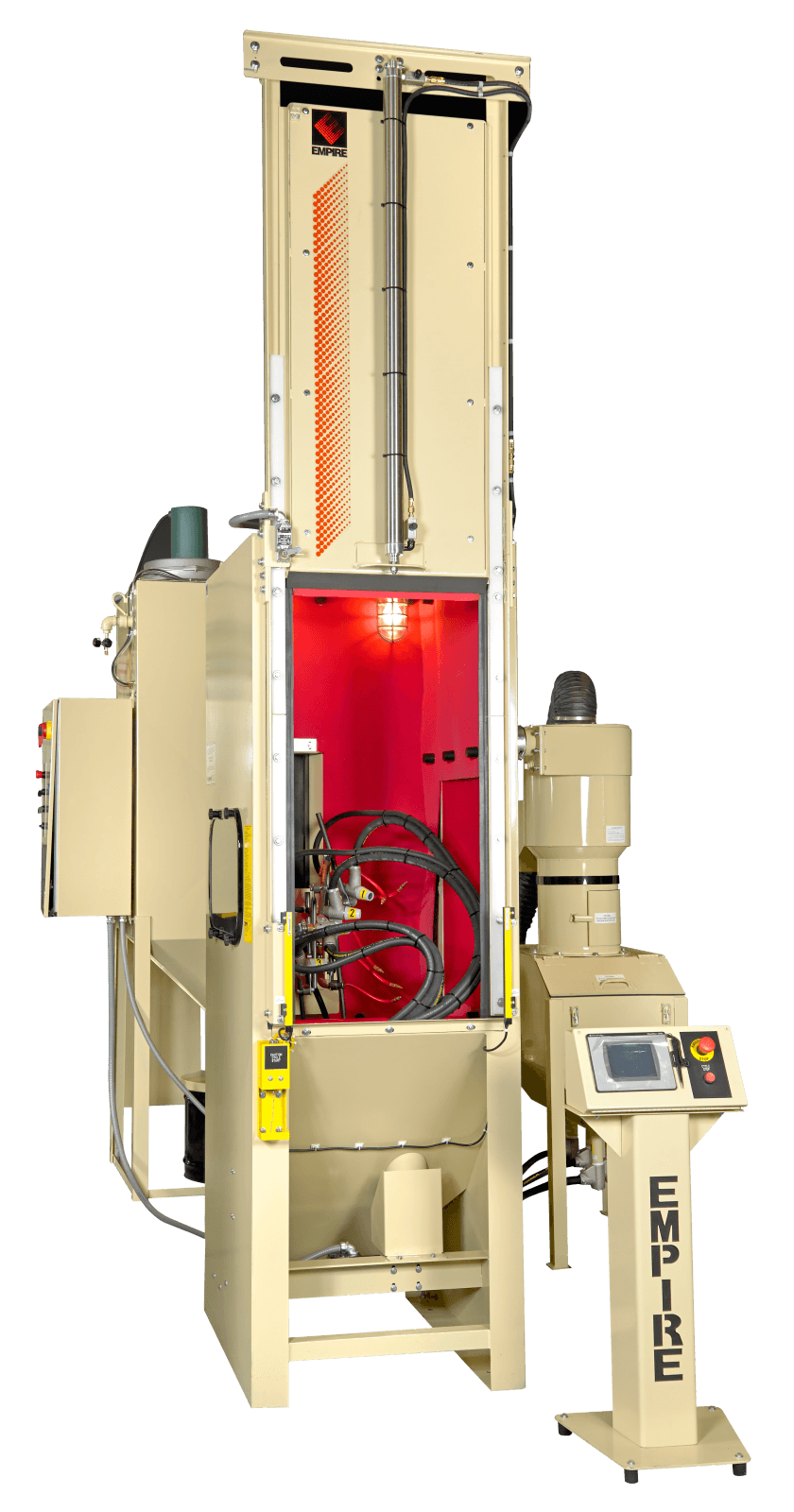

Manuel Wet Blasting Cabinet

Manual wet blasting cabinets are ideal for a facility that have multiple types of parts needing to pass through a wet blast system.

Portable Wet Blasting Equipment

The Wetblast FLEX brings wet blasting to the mobile job site, mixing the media and water at the nozzle to ensure your media stays dry.

Wet Blasting vs Dry Blasting

There is a lot to consider when trying to decide between wet and dry blasting. We have a more in-depth article on the topic here. Below is a quick overview on ideal applications for wet blasting vs dry blasting.

Ideal Wet Blast Applications:

- Medical Parts

- Aerospace – Composites and Metals

- Automotive

- Firearms

- Remanufacturing

Lab Development Process

We run lab tests on your parts to dial in the best euipment and media seleection for your project! Talk to our team today to schedule the lab test.

Blending Machine Lines Using Wet Blasting Equipment

Wet blast equipment efficiently smooths out lines and defects on machined parts. The media/water combonation allows for precise control to minimally hit the surface to blend without removing metal.

Recent Comments