Why Tumbling Media Shape Matters

Why Tumbling Media Shape Matters

A Media Shape Resource Guide

Tumbling media comes in many sizes, compositions, and shapes. Each of these factors are a crucial decision within your finishing application. We’re going to breakdown the various shapes of tumbler media in this article. Here is a list of various shapes:

- Spheres and Balls

- Triangles

- Pyramids

- Pins

- Arrowheads

- Wedges

- Ellipses

- Nuggets

- Cylinders

- Quadrants

- Cones

- Ball Cones

- Ovals

- Stars

- Four-pointed stars

- Diamonds

- Tetrahedrons

- Random Shapes

Importance of Tumbler Media Shape

The various shapes of tumbler media all have different advantages for specific tumbling applications. The main items you need to consider when selecting a size are:

- The ability for the media to cover the full surface area of the part being tumbled.

- Media will not lodge in any holes or recesses.

- Speed and smooth flow through the tumbler.

- Allow for easy separation of media from the parts at the end of the cycle.

There are times when using a combination of media shapes is the best process for an application.

Triangle Media

Triangular tumbler media is ideal for harder to reach corners and slots on parts. The flat parts of the triangles are effective on straight edges while the edges provide coverage into the smaller areas. Triangular media consists of triangles, arrowheads, and angle-cut triangles, often used in cleaning and deburring applications.

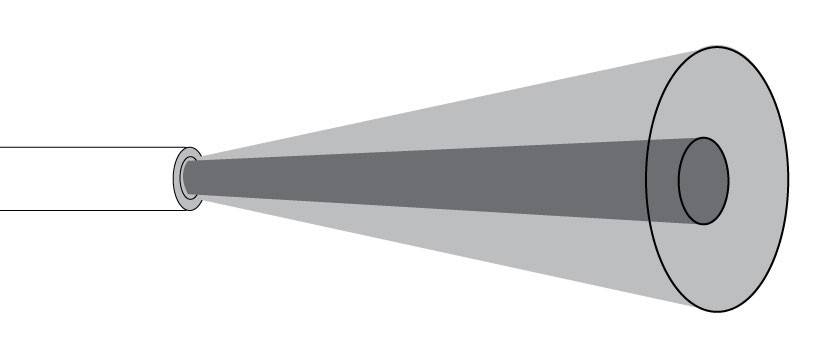

Cone Media

Conical tumbling media is effective for entering holes and passageways on parts without lodging. Typically used in applications that require aggressive action, ball cones are often used for burnishing.

Sphere Media

Spherical tumbling media is ideal for blending and smoothing surfaces. The round shape creates good flow and movement through the tumbler.

Wedge Media

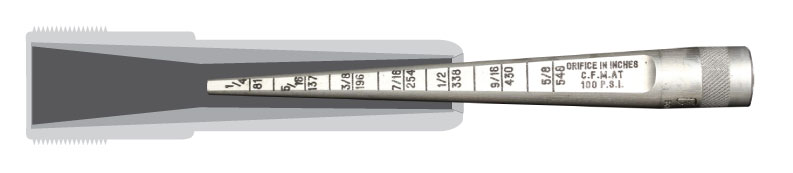

Wedge-cut tumbling media, or often referred to as V-cut cylinders, is a versatile shape that can be effective for many applications.

Cylinder Media

Cylindrical media is ideal for deburring holes and contours. The angled ends are effective at reaching into recesses on parts. Cylinders are also very efficient at removing rust from parts.

Oval Media

Oval tumbling media provides a larger surface-to-surface coverage than spheres, while still providing good flow and motion through the tumbler. Ovals are often used in barrel tumbling applications.

The composition of the media will have an affect on the available media shape options. Stainless steel media can’t be made into all of the same shapes as ceramic and plastic.

Process Testing

Testing your tumbling process is vital for selecting the right media. Send us your parts and our processing lab will determine the right media shape and type for your finishing application.

Recent Comments